NOTE: The grease seal will accept the grease

pressure without damaging the seal, and is de-

signed to have grease pumped out through it

during lubrication. Even if grease leaks out

around the top or bottom plate, continue pump-

ing until new grease is seen at the seal on the

bushing opposite the grease fitting.

When lubricating knuckle pin bushings after the IM

maintenance interval, first wipe the lube fittings

clean. Then apply multipurpose chassis grease until

new grease is seen at the grease seal on the bush-

ing opposite the fittings.

33–02 Tie-Rod End Lubricating

and Inspecting

IMPORTANT: DOT roadside tie-rod assembly

replacement criteria specifies that if tie-rod end-

play is 1/8 inch (3 mm) or greater, measured on

the road, the vehicle must be taken out of ser-

vice immediately. If less than 1/8 inch (3 mm),

the vehicle does not have to be taken out of

service but a major out-of-service inspection

and maintenance must be scheduled as soon

as possible.

1. For any Detroit or Meritor axle that requires lubri-

cation of the tie-rod ends, wipe the grease fit-

tings clean, then pump multipurpose chassis

grease, NLGI Grade 1 (6% 12-hydroxy lithium

stearate grease) or NLGI Grade 2 (8% 12-

hydroxy lithium stearate grease), into the tie-rod

ends until all used grease is forced out and fresh

grease is seen at the ball stud neck. See

Fig. 4.

NOTE: Inspect the tie-rod end boots for cracks,

wear, or damage. If a boot is cracked, worn, or

damaged, replace the tie-rod assembly.

2. Inspect the tie-rod ends, as follows.

2.1 Shake the cross-tube. Movement or

looseness between the tapered shaft of

the ball and the cross-tube socket mem-

bers means that the tie-rod end assembly

must be replaced.

2.2 The threaded portion of the tie-rod end

assembly must be inserted all the way

into the cross-tube split for adequate

clamping. See

Fig. 5. Replace the parts if

this cannot be done. For instructions, see

the axle manufacturer’s service manual.

2.3 Check the tie-rod end nut and clamp nut

torques. For Meritor axles, tighten the tie-

rod end nut 100 lbf·ft (136 N·m), and

tighten the clamp nut 40 to 55 lbf·ft (54 to

75 N·m). For Detroit axles, see

Table 1

for tie-rod end nut torque specifications

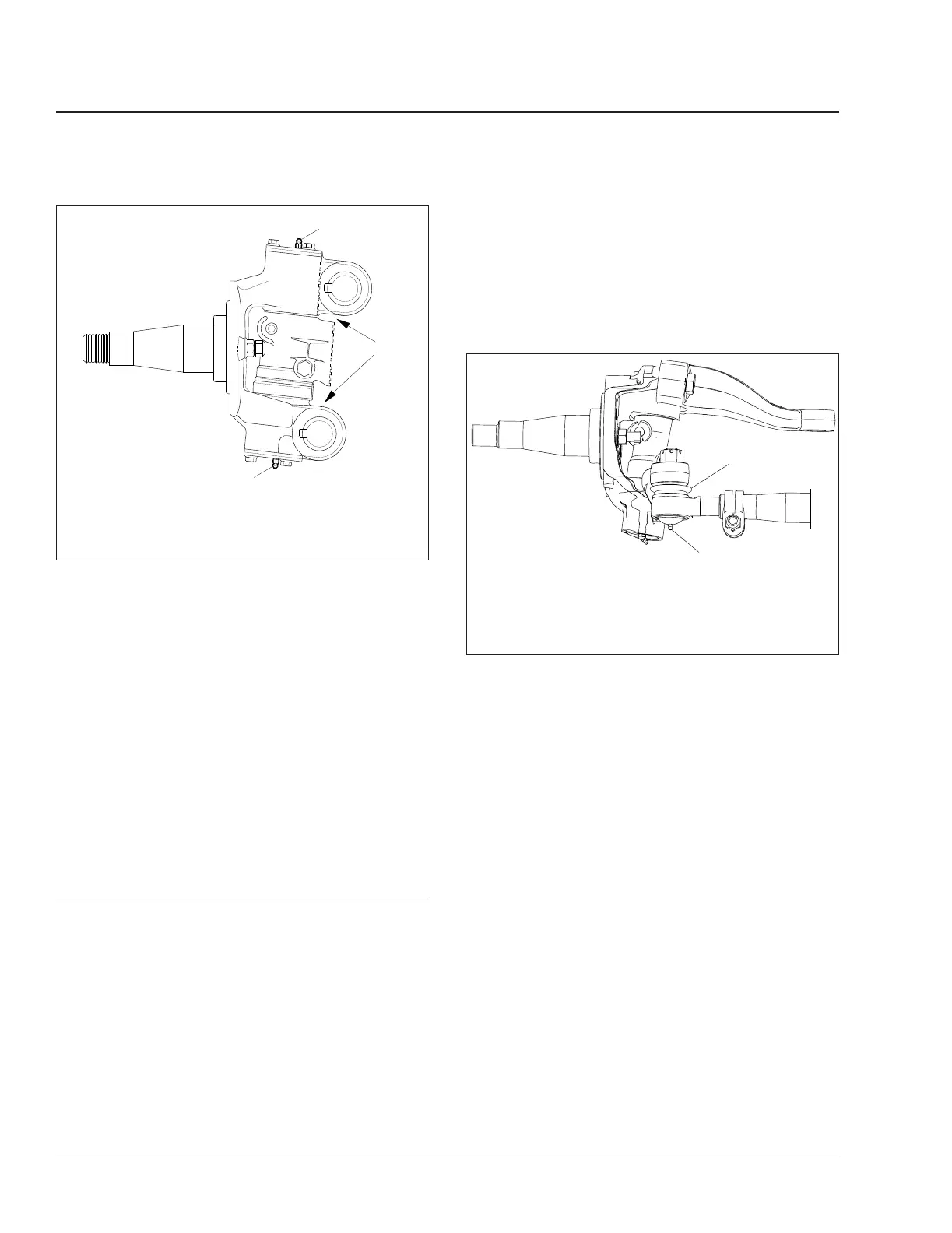

09/06/96 f320032a

A

1

1

Pump lubricant into each grease fitting until fresh grease

comes out at A.

1. Grease Fitting

Fig. 3, Meritor Axle Grease Fittings

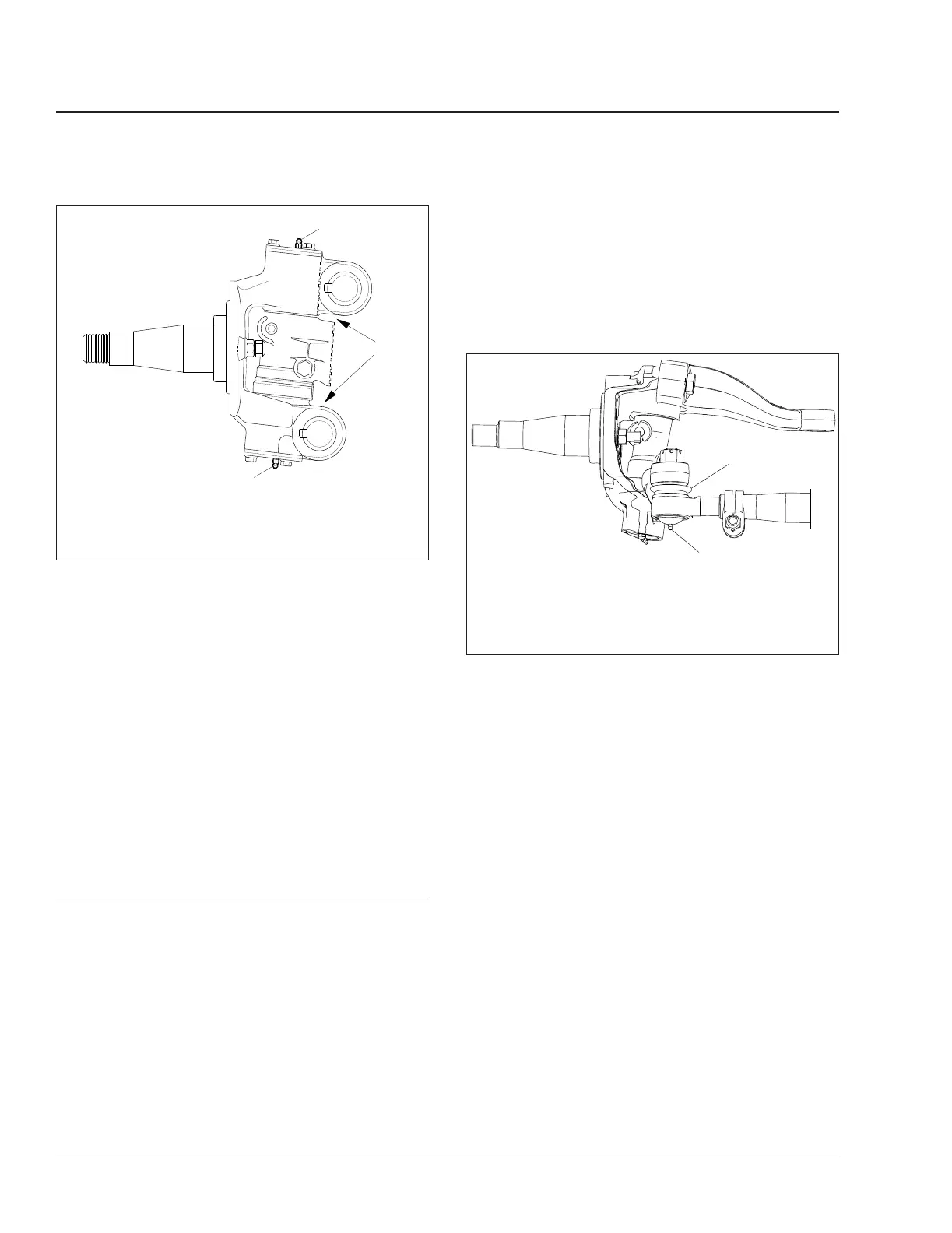

06/12/2012 f330273

1

2

NOTE: No grease should emit from the tie-rod boot. If

grease emits from the tie-rod boot, the boot is dam-

aged.

1. Grease Fitting 2. Boot

Fig. 4, Grease Fitting and Boot (Detroit axle shown)

Front Axle33

Recreational Vehicle Chassis Maintenance Manual, June 201533/2

Loading...

Loading...