and Table 2 for tie-rod end clamp nut

torque specifications.

Detroit Axle Tie-Rod End Nut

Thread Torque: lbf·ft (N·m)

5/8–16 60 to 115 (81 to 156)

5/8–18 60 to 115 (81 to 156)

3/4–16 90 to 170 (122 to 230)

7/8–14 160 to 300 (217 to 407)

Table 1, Detroit Axle Tie-Rod End Nut

Detroit Axle Tie-Rod End Clamp Nut

Thread Torque: lbf·ft (N·m)

1/2–13 35 to 45 (47 to 61)

5/8–11 40 to 60 (54 to 81)

5/8–18 50 to 64 (73 to 87)

3/4–10 155 to 175 (210 to 237)

Table 2, Detroit Axle Tie-Rod End Clamp Nut

33–03 All-Axle Alignment

Checking

NOTE: The final stage manufacturer is respon-

sible for setting the vehicle ride height with air

suspension and some vehicle alignments. On

full-railed chassis, this includes the final toe-in

setting on the front axle. For modular style

chassis, both the front axle toe-in and rear axle

thrust angle settings are included.

Drive Axle Alignment Checking

NOTE: The maximum tolerance from perpen-

dicular for rear axle alignment should be ±0.25

degree.

Check the axle alignment, parallelism, and thrust

angle measurements for the rear axle. Use the appli-

cable procedure and specifications in Group 35 of

the Recreational Vehicle Chassis Workshop Manual,

or take the vehicle to an authorized Freightliner

dealer.

Toe-In Inspection

For vehicle alignment to be accurate, the shop floor

must be level in every direction. The turn plates for

the front wheels must rotate freely without friction,

and the alignment equipment must be calibrated

every three months by a qualified technician from the

equipment manufacturer. Freightliner dealers must

have proof of this calibration history.

NOTE: Toe-in should be within 0 to 1/32 inch

(0.8 mm).

1. Apply the parking brake, and chock the rear

tires.

2. Raise the front of the vehicle until the tires clear

the ground. Check that the safety stands will

support the combined weight of the body, axle,

and frame. Place safety stands under the axle.

3. Using spray paint or a piece of chalk, mark the

entire center rib of each front tire.

4. Place a scribe or pointed instrument against the

marked center rib of each tire, and turn the tires.

Hold the scribe firmly in place so that a single

straight line is scribed all the way around each

front tire.

f320033a

1

OK

OK

02/27/2007

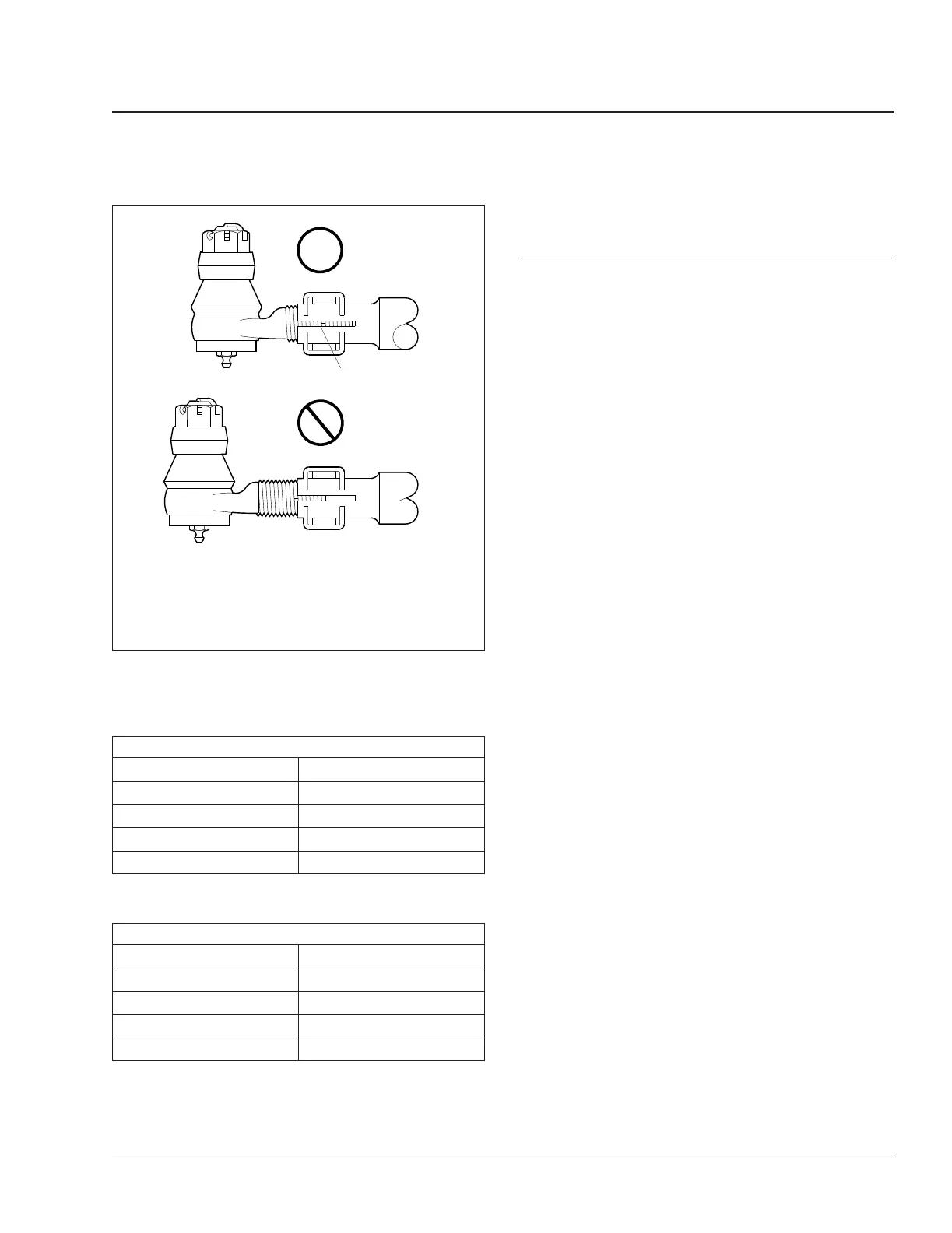

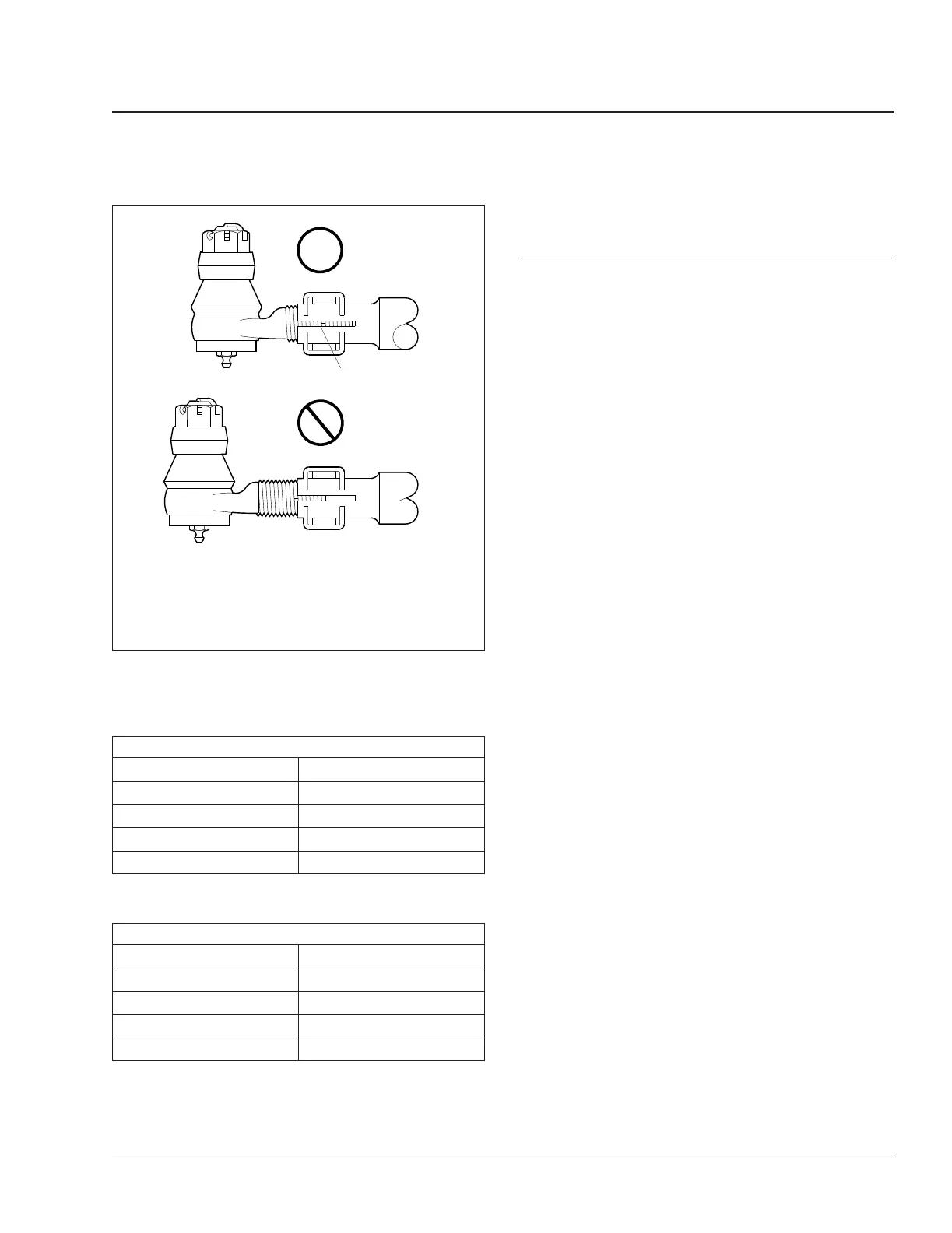

IMPORTANT: The tie-rod end threads must be visible

throughout the entire length of the split.

NOTE: Pinch bolt not shown to provide clarity.

1. Cross-Tube Split

Fig. 5, Tie-Rod End Adjustment

Front Axle 33

Recreational Vehicle Chassis Maintenance Manual, June 2015 33/3

Loading...

Loading...