18

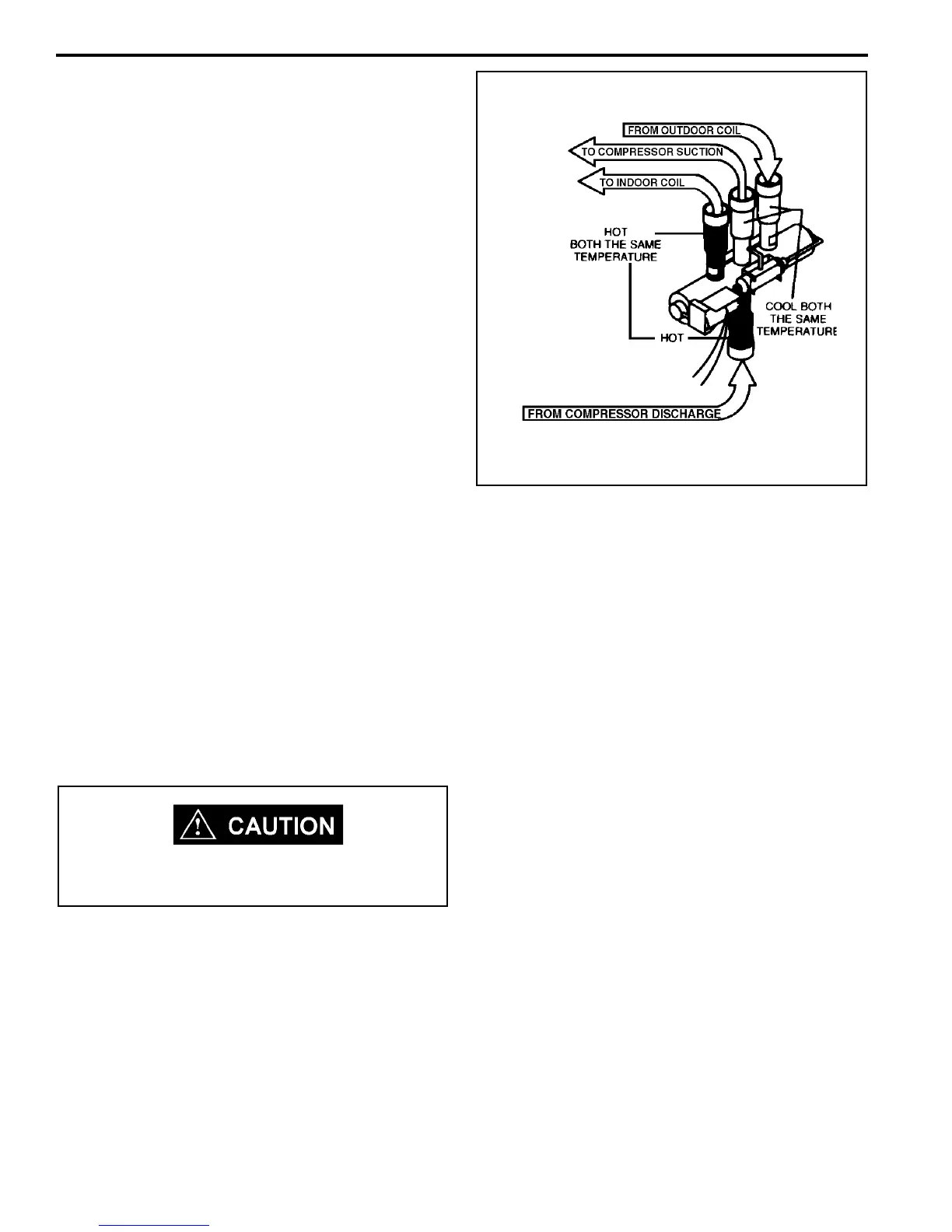

Touch Test in Heating/Cool ing Cycle

The only definite indications that the slide is in the

mid-position is if all three tubes on the suction side of the

valve are hot after a few minutes of running time.

NOTE: A condition other than those il lus trat ed above, and

on Page 28, indicate that the re vers ing valve is not shift ing

prop er ly. Both tubes shown as hot or cool must be the same

corresponding tempera ture.

Procedure For Changing Reversing Valve

1. Install Process Tubes. Recover refrigerant from sealed

sys tem. PROPER HANDLING OF RECOVERED RE-

FRIG ER ANT AC CORD ING TO EPA REG U LA TIONS

IS RE QUIRED.

2. Remove solenoid coil from reversing valve. If coil is to be

reused, protect from heat while changing valve.

3. Unbraze all lines from reversing valve.

4. Clean all excess braze from all tubing so that they will

slip into fi ttings on new valve.

5. Remove solenoid coil from new valve.

6. Protect new valve body from heat while brazing with

plastic heat sink (Thermo Trap) or wrap valve body with

wet rag.

7. Fit all lines into new valve and braze lines into new

valve.

Reversing Valve in Heating Mode

TESTING THE COIL

1. Turn off high voltage electrical pow er to unit.

2. Unplug line voltage lead from re vers ing valve coil.

3. Check for electrical continuity through the coil. If you

do not have con ti nu ity re place the coil.

4. Check from each lead of coil to the cop per liquid line as

it leaves the unit or the ground lug. There should be no

con ti nu ity between either of the coil leads and ground;

if there is, coil is grounded and must be replaced.

5. If coil tests okay, reconnect the elec tri cal leads .

6. Make sure coil has been assembled cor rectly.

Checking the Reversing Valve

NOTE: You must have normal op er at ing pressures before

the reversing valve can shift.

Check for proper refrigerant charge. Slug gish or sticky

reversing valves can some times be remedied by reversing

the valve several time with the airfl ow re strict ed to increase

system pres sure.

To raise head pressure during the cool ing season the

airfl ow through the out door coil can be restricted . During

heating the indoor air can be restricted by blocking the

return air.

Dented or damaged valve body or cap il lary tubes can

prevent the main slide in the valve body from shifting.

If you determine this is the prob lem, re place the reversing

valve.

After all of the previous inspections and checks have been

made and de ter mined cor rect, then perform the "Touch

Test" on the reversing valve.

Never energize the coil when it is re moved

from the valve as a coil burn out will result.

Loading...

Loading...