20

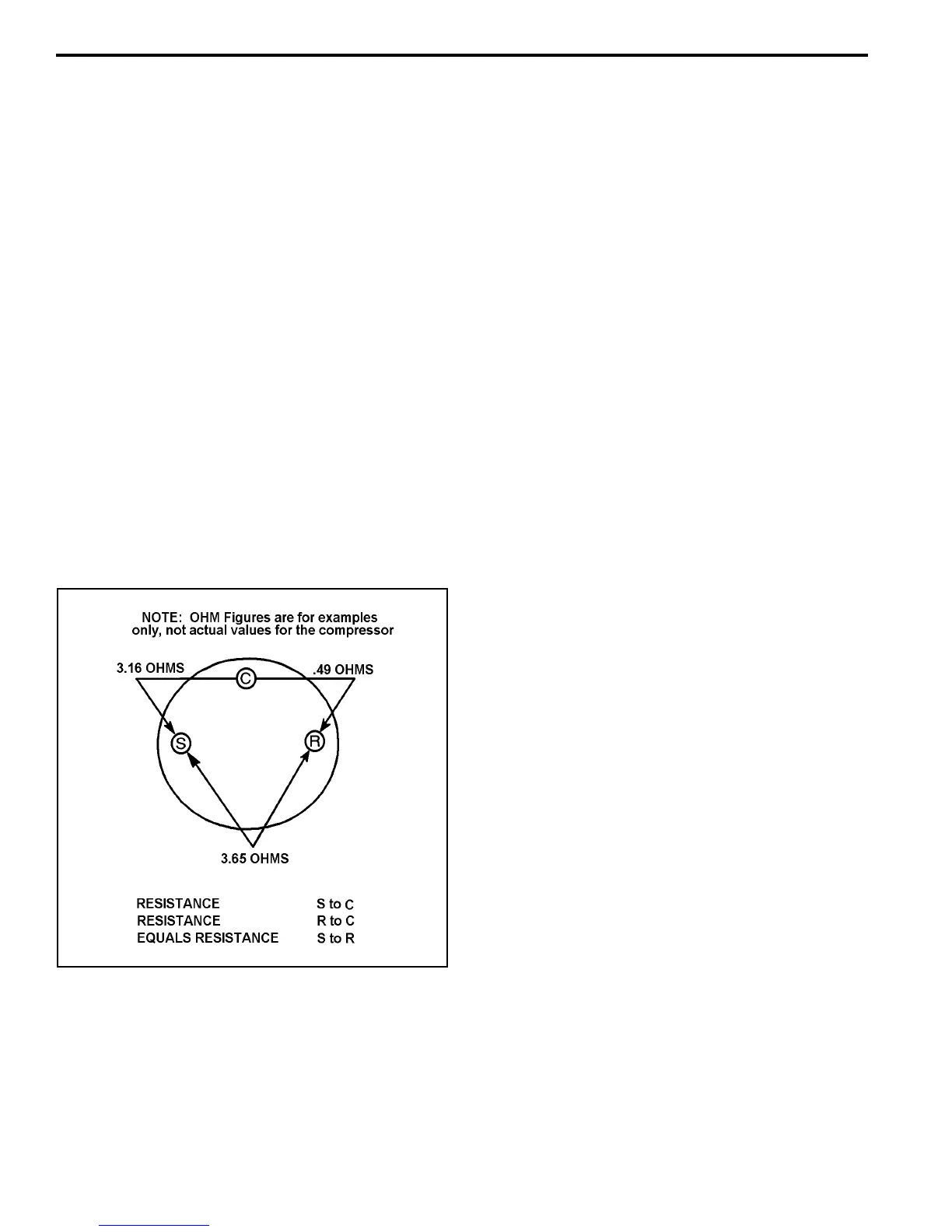

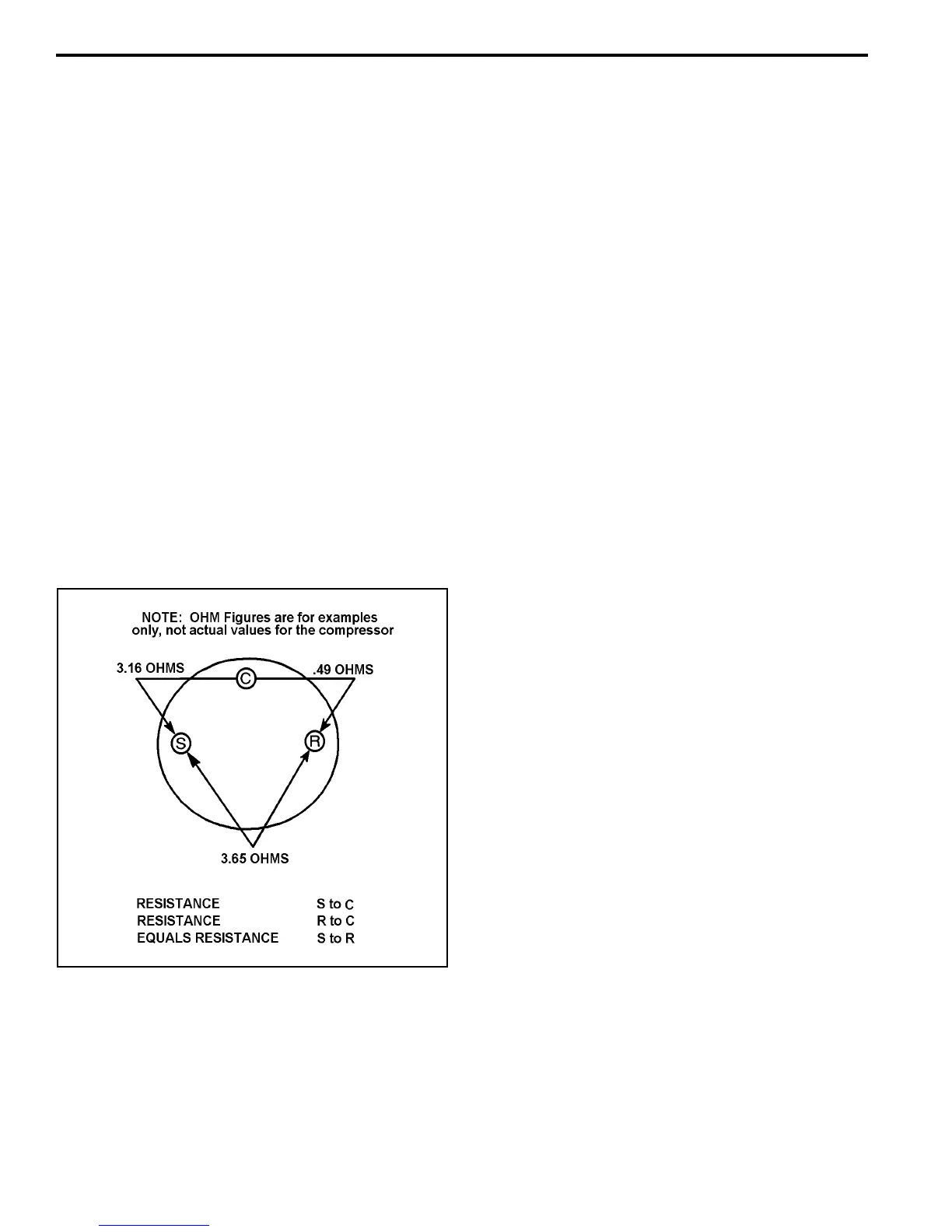

Single Phase Resistance Test

Remove the leads from the com pres sor ter mi nals and set

the ohm me ter on the low est scale (R x 1).

Touch the leads of the ohmmeter from ter mi nals com mon

to start ("C" to "S"). Next, touch the leads of the ohm me ter

from ter mi nals com mon to run ("C" to "R").

Add values "C" to "S" and "C" to "R" to geth er and

check resistance from start to run ter mi nals ("S" to "R").

Re sis tance "S" to "R" should equal the total of "C" to "S"

and "C" to "R."

In a single phase PSC compressor mo tor, the highest

value will be from the start to the run connections (“S” to

"R"). The next highest resistance is from the start to the

common con nections ("S" to "C"). The lowest resistance

is from the run to com mon. ("C" to "R") Before re plac ing a

com pres sor, check to be sure it is de fec tive.

Check the complete electrical sys tem to the com pres sor

and compressor internal elec tri cal system, check to be

certain that compressor is not out on internal over load.

Complete evaluation of the system must be made when ev er

you suspect the com pres sor is defective. If the com pres sor

has been operating for some time, a careful ex am i na tion

must be made to determine why the com pres sor failed.

Many compressor failures are caused by the fol low ing

conditions:

1. Improper air fl ow over the evaporator.

2. Overcharged refrigerant system caus ing liq uid to be

re turned to the compressor.

3. Restricted refrigerant system.

4. Lack of lubrication.

5. Liquid refrigerant returning to com pres sor causing oil

to be washed out of bear ings.

6. Noncondensables such as air and mois ture in

the system. Mois ture is ex treme ly de structive to a

refrigerant sys tem.

Recommended procedure for compressor

replacement

NOTE: Be sure power source is off, then dis con nect

all wiring from the com pres sor.

1. Be certain to perform all necessary elec tri cal and

re frig er a tion tests to be sure the compressor is actually

de fec tive be fore re plac ing .

2. Recover all refrigerant from the sys tem though

the pro cess tubes. PROPER HAN DLING OF

RECOVERED RE FRIG ER ANT ACCORDING TO

EPA REG U LA TIONS IS REQUIRED. Do not use

gauge manifold for this purpose if there has been

a burnout. You will con tam i nate your man i fold and

hoses. Use a Schrader valve adapt er and copper

tubing for burnout failures.

3. After all refrigerant has been re cov ered, disconnect

suction and dis charge lines from the compressor and

remove compressor. Be certain to have both suc tion

and discharge process tubes open to at mo sphere.

4. Carefully pour a small amount of oil from the suction

stub of the de fec tive com pres sor into a clean

con tain er.

Loading...

Loading...