18

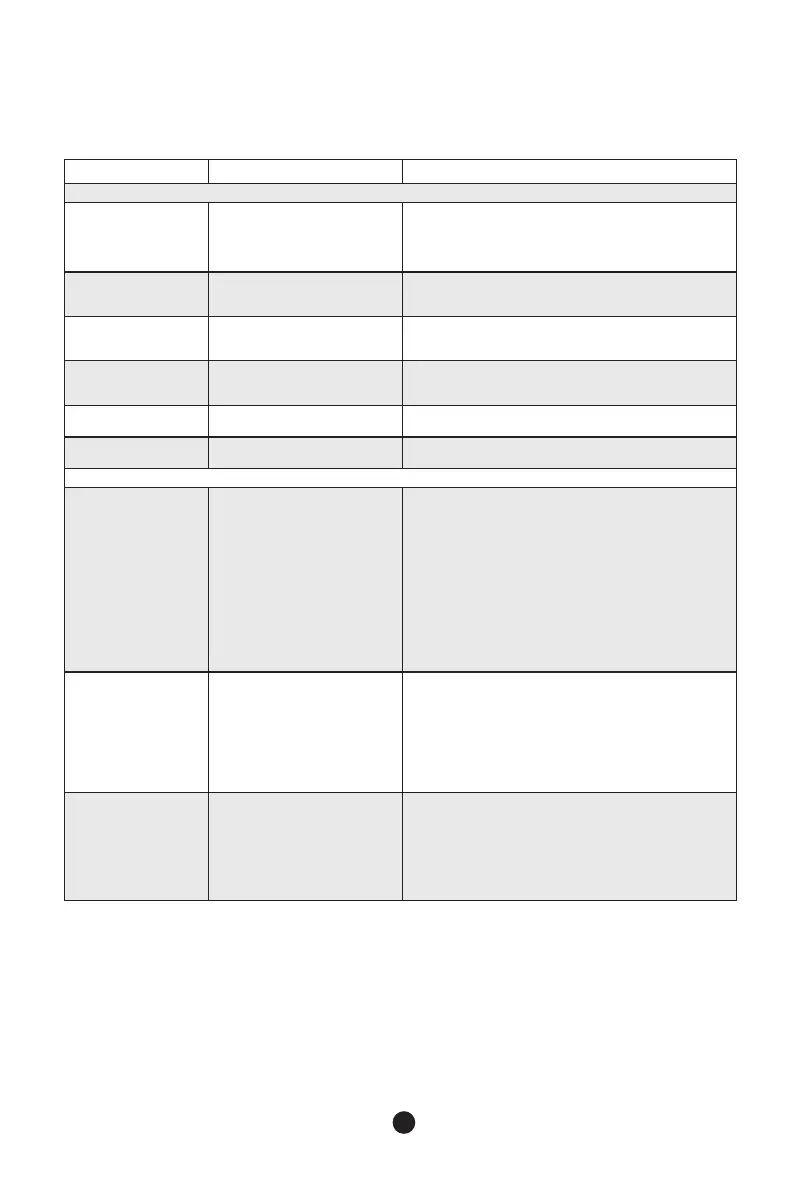

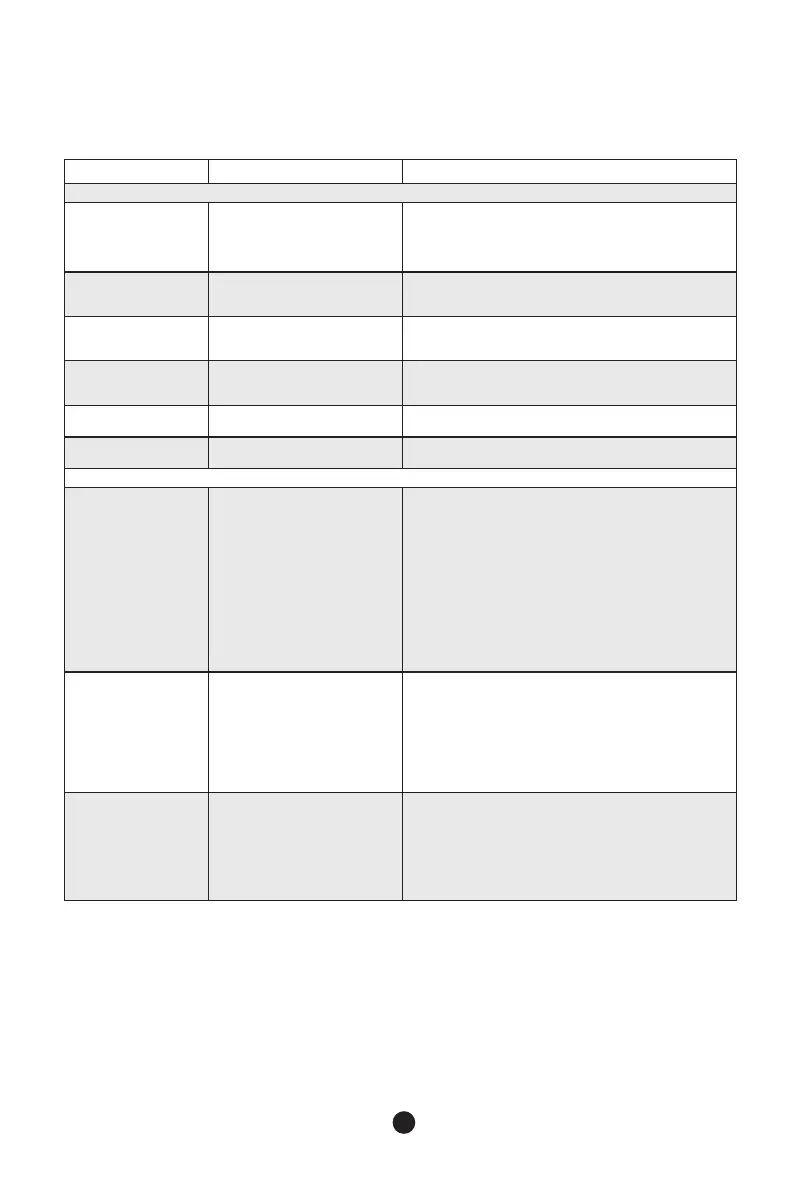

CONCERN POTENTIAL CAUSE COMMON SOLUTION

SOUND AND NOISE

Louder sound levels

whenever keg cooler

is on.

• Modern keg coolers have in-

creased storage capacity and

more stable temperatures. They

require a high-efficiency compres-

sor.

• This is normal. When the surrounding noise level is low, you

might hear the compressor running while it cools the interior.

Longer sound levels

when compressor

comes on.

• Keg cooler operates at high

pressure during the start of the

“ON”

cycle.

• This is normal. Sound will level off or disappear as the keg

cooler continues to run.

Popping or cracking

sound when compres-

sor comes on.

• Metal parts undergo expansion

and contraction, as in hot water

pipes.

• This is normal. Sound will level off or disappear as the keg

cooler continues to run.

Bubbling or gurgling

sound like water boil -

ing.

• Refrigerant (used to cool keg

cooler) is circulating throughout

the system.

• This is normal.

Vibrating or rattling

noise.

• Keg cooler is touching the wall. • Move keg cooler slightly away from the wall.

Snapping noise. • Temperature control turning keg

cooler on and off.

• This is normal.

COMMON DRAFT PROBLEMS

WILD BEER - Beer,

when drawn, is all

foam, or too much

foam and not enough

liquid beer.

• Beer drawn improperly.

• Creeping regulator.

• Applied pressure is set too high.

• Hot spots in line.

• Tapped into a warm keg (should

be 1.1

°C-3.5°C(34°F-38°F)

• Centre malfunctioning.

• Faucet is in bad, dirty or worn

condition.

• Make sure faucet is opened all the way. Close quickly when

done.

• Replace with a new regulator.

• Readjust regulator to a lower pressure until foam subsides.

When pressure is properly set, you should be able to pour 10

oz. of beer in (5)five seconds.

• Make sure beer del

ivery line is not pinched and is fully inside

the interior of the keg cooler.

• Wait until keg cools down to proper temperature.

• Have keg cooler serviced to return it to proper operating

condition.

• Thoroughly clean faucet with recommended cleaning kit.

Replace all worn seals.

FLAT BEER - Foamy

head disappears

quickly; beer lacks

usual zestful brewery

• Dirty glasses.

• Applied pressure is set too low.

• CO

2

is cut off.

• Beer too cold.

• Loose tap or vent connections.

• Sluggish regulator.

• Wash glasses using soap-free detergent.

• Increase pressure until beer at a rate of 2 oz. per

second.

• Do not turn off CO

2

supply line to keg until keg is empty and

ready to be removed.

• Increase temperature of keg cooler. See SETTING THE

TEMPERATURE CONTROL section.

• Check that coupler is properly installed in keg.

• Replace regulator.

CLOUDY BEER - When

beer in glass appears

hazy, not clear.

• Frozen or near frozen beer.

• Unrefrigerated beer for long periods

of time.

• Dirty glasses.

• Dirty faucet.

• Unrefrigerated foods placed on top

of cold keg.

• Return keg to place of purchase and exchange for one that

has been properly refrigerated.

• Exchange keg for fresh one.

• Wash glasses using soap-free detergent.

• Clean faucet with recommended cleaning kit.

• Remove items from atop k

eg and place in a separate refrig-

erator.

fresh flavour.

flows

Loading...

Loading...