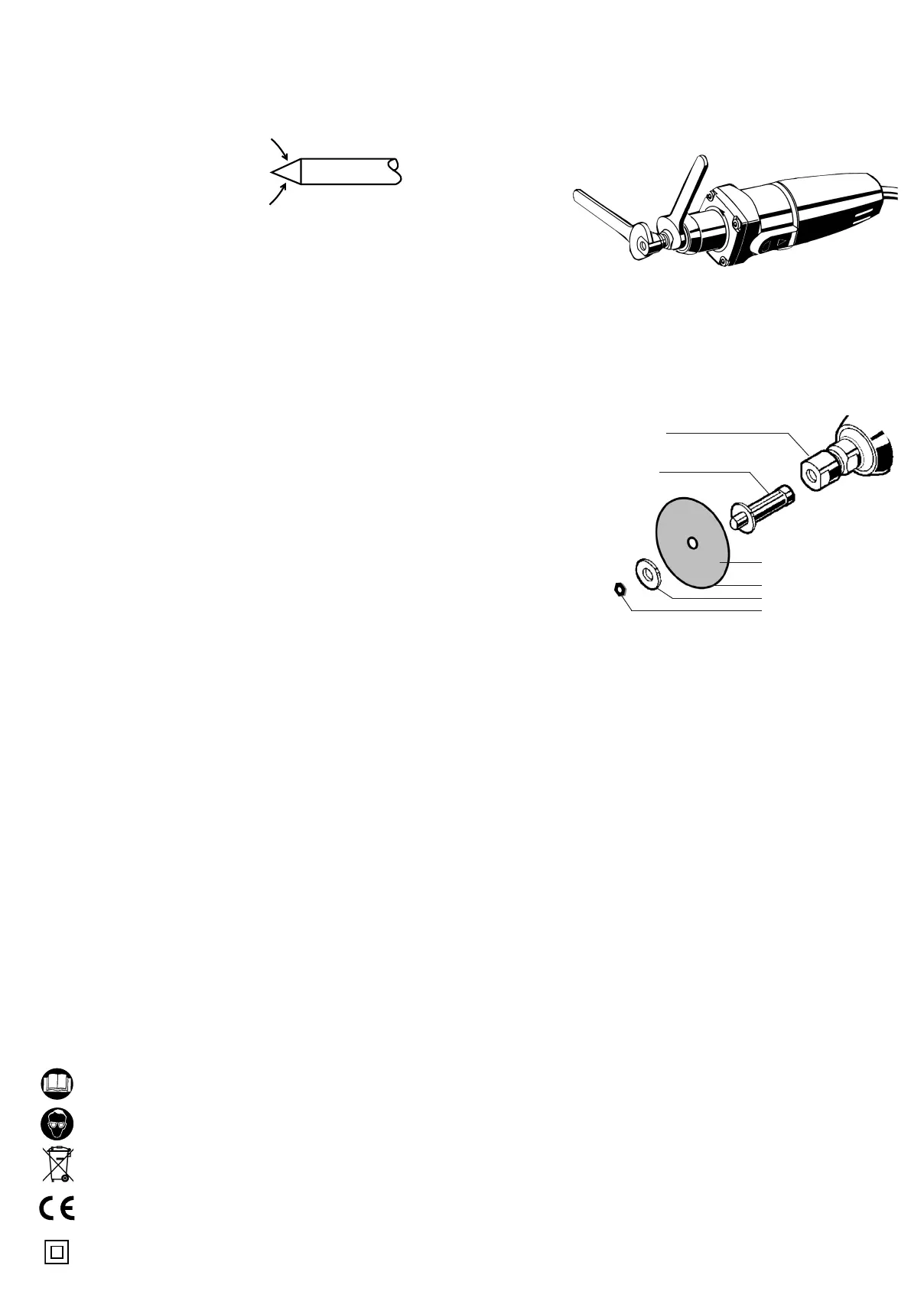

Spindle + Nut

Wheel take-off shaft

Coated side

of wheel

Wheel

Washer

Nut

GENERAL SAFETY INSTRUCTIONS

USEFUL TIPS

SYMBOLS

Read the instructions before

using this equipment.

Protect your eyes ! Wear safety goggles when using this equip-

ment.

Removal of used equipment, this tool can be disposed, free of

charge , at indicated local agencies.

This equipment has been tested according to

2014/30/EU,2006/42/EC,2011/65/EU

EN60745-1:2009+A11:2010,EN60745-2-23:2013.

Safety class II, safety insulation

7. How to Use :

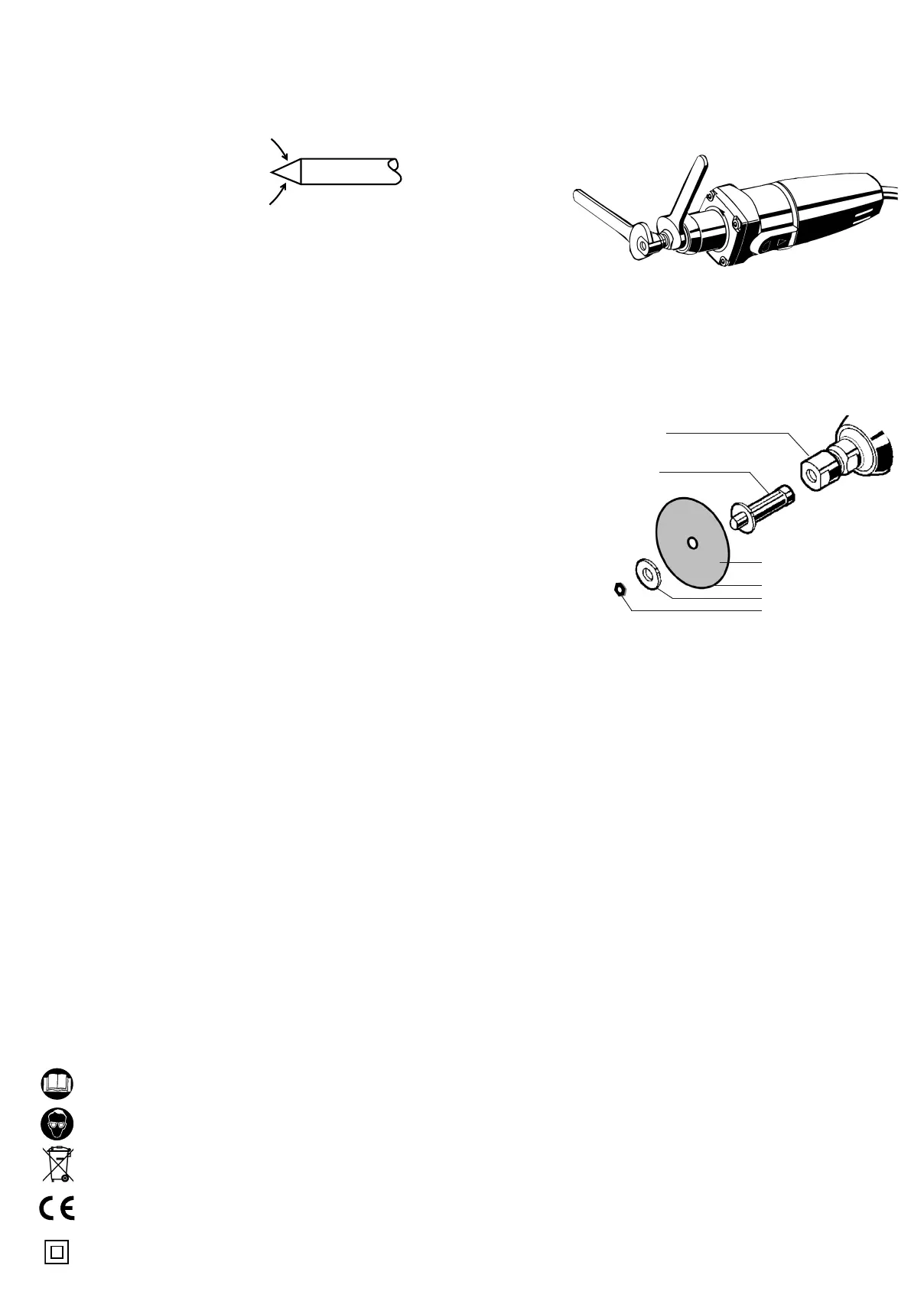

● Makeadjustmentsfortheangleofthepoint(indegrees)

and the electrode diameter

- Loosen the central screw on the head

- Set the degree and the electrode

diameter by turning the head

- Tighten the central screw

The number of degrees equals the angle

ofthepointonthesharpenedelectrode:

● Guide the tungsten electrode through the opening that coincides with its

diameter;

● TurnontheTIGGRINDERMOBILE;

● Carefully press the tungsten electrode onto the revolving disc, while at the

same time rotating it with light pressure;

● Continue to rotate the electrode as it is removed from the disc until there is

no longer any contact;

● Inspect the results and, if necessary, repeat the process;

● The multi-functional cover with integrated opening slide makes it possible to

surface grind electrodes that have welding deposits due to the welding

process. In addition, ground electrodes can be optimised for aluminium

welding by being given a truncate cone.

● 3stepsadjustmentfortripleuseofthegrindingdiscbyturningthegrindingin

position 1,2 or 3.

Warning ! Do not sharpen bent or burnt electrodes. Remove any drops on the point

of the electrode before it is sharpened. Use the electrode holder for short electrodes.

BRIEF DESCRIPTION

CHANGING THE GRINDING WHEEL

Remove the plug from the electrical socket before doing any maintenance on

this machine !

● LoosentheM6screwsandremovethemcompletely

● Removeheadshowingtheangleadjustment

● Loosen the stud bolts on the sides

● Remove the house

● Loosen and unscrew the tension nut

● Change the wheel

● Warning ! Ensure that the wheel is mounted correctly

● Replace the washer

● Screw the nut back on and tighten it

CHANGING THE WHEEL MOUNT

Remove the plug from the electrical socket before doing any maintenance on

this machine !

● Position spanner SW 13 on the spindle

● PositionspannerSW19onthenut

● Loosen the nut

● Replace the wheel mount

● Tighten the nut

Followthesame

procedure to change

thespringcollet,except

that the nut must be completely

unscrewed in order for the spring to be changed.

Theseproceduresmustbefollowedexactlyastheyareexplainedandillustrated.

Remove the plug from the electrical socket before doing any maintenance on

this machine !

The tension rod must have the same diameter

as the take-off shaft; otherwise the tension

rod will be damaged.

Fitthetake-offshaftinto

the tension rod.

The take-off shaft must rest

on the nut.

Very important !!!

Position spanner SW 13

on the spindle and tighten

thenutwithSW19.

Place the wheel on

thetake-offshaft.Ensure

that it is properly mounted

and not crooked. Put on the

washer, screw on the nut and

tighten with spanner SW 10.

PAYATTENTION.Pleaseobservethesesafetyguideli-

nes.Notfollowingthemcancauseelectricalshock,re

and/orheavyinjuiries.Thefollowingconcept”electrical

tool”concernstoolswithelectricalexasalsotools

with build-in batteries.

PLEASEGUARDTHESEINSTRUCTIONSCARE-

FULLY;

1. Working place.

a) Keepittidyandclean.Disorderandlowlightcan

occur accidents.

b) Don’tusethetoolinandangerousexplosiveen-

vironment,whereammableproducts,gasesand

dustarepresent.Electricaltoolsproducesparkles,

that can ignite the dust or gases.

c) Keepchildrenandotherpersonsawaywhenusing

anelectricaltool.Withanunexpecteddeviationone

can loose control on the tool.

2.Electrical safety.

a) Theplugandsocketmustbeappropriate.Don’t

changethepluganddon’tuseanadaptertogether

with an earthed tool. Unchanged plug and socket

decrease the risk of electrical shocks.

b) avoidbodycontactwithearthedsurfaces,suchas

pipes,radiators,stoves and refrigerators. There is a

high risk of electrical shock if your body is earthed..

c) Protectthetoolfromrainandhumidity.Water

penetration can cause electrical shock.

d) Don’tusetheexasahandletocarrythetool,for

hanging it on the wall or to pull out the plug from

thesocket.Keeptheexfarfromheat,oil,sharp

edges or revolving parts of equipment. Damaged

ortwistedexesincreasestheriskofelectrical

shocks.

e) Whenworkingoutsideonlyuseextensionexes

that has been approved for outdoor use. Doing so

one decreases the risk of electrical shock.

3. Safety of people.

a) Beattentive,lookwhatyouaredoing,andbe

ingenious when working with an electrical tool.

Don’tusethetoolwhenyouaretiredorunderthe

inuenceofdrugs,alcoholormedicine.Oneshort

momentofinattentioncanleadtosevereinjuries.

b) Alwayswearpersonalprotectionequipment,such

as safety goggles,anti slip shoes,safety helmet

orearmufes,dependingonthetypeofelectrical

toolsinuse.Doingsoreducestherisksofinjuries.

c) Preventtheequipmentfromstartingunexpectedly.

Makesurethattheswitchison”off”beforeplug-

ging in. Never carry equipment that is connected

withyourngeronthepowerswitch.

The best results will be obtained by applying light pressure to the electrode while

at the same time rotating it on the disc. Remove the electrode before turning off

the grinder.

Using too much pressure while grinding will damage the grinder and require more

grinding discs; performance will suffer.

Warning : Always keep the air-intake vents clean.

Accessories :OnlyuseFRONIUSaccessoriesandspareparts.

Spare parts :

Order No.

Grinding wheel 42,0411,0012

PleaserefertotheFRONIUSProductCatalogueforotherreplacementparts,or

ask your dealer.

d) Checkbeforestartingthatthekeyandadjustment

tools have been removed.

e) Don’toverestimateyourself.Makesuretohavea

secure posture and balance. Doing so ,you are in

better position to control the tool.

f) Wearthecorrectclothing.Don’twearlooseclothing

orjewellery.Keeplonghair,clothesandgloves

away from revolving parts.

g) Ifmountingfume-andordust-extractorsmake

sure that they are connected and used the right

way. Doing so is avoiding dust-problems.

4. Carefully handling and use of electrical tools.

a) Don’toverloadthetool.Foreveryjobusethe

appropriate electrical tool. Doing so you will obtain

a better and safer result .

b) Don’tuseanelectricaltoolwithadefectswitch.A

toolwithadefectswitchcannotbeswitched”off”

or”on”,isdangerousandmustberepaired.

c) Pullouttheplugfromthesocketbeforeyouwish

tochangetheadjustments,changesomeparts

or putting away the tool. These measures prevent

unexpectedstartofthetool.

d) Keepunemployedelectricaltoolsoutofreachof

childrenDon’tleavethistoolinhandsofpeoplenot

usedtohandleitorhaven’tnotreadtheseinstruc-

tions.Electricaltoolsaredangerouswhenusedby

inexperiencedpersons.

e) Takecareofyourtool.Pleasecontrolifeverytur-

ningpartcanworkfreelyandisn’tblocked,orthat

some parts are broken or damaged. Let the tool

berepairedbeforeuse.Manyaccidentsaredueto

badly maintenance of electrical tools.

f) Keepcuttingtoolscleanandsharp.Doingsoone

getsabettergripandeasierjobdone.

g) Onlyuseelectricaltools,sparesaso,conformthese

instructions for this tool .Take also into conside-

rationtheenvironmentandthejobthathastobe

done. The use of electrical tools for inadequate

jobscanleadtodangeroussituations.

5. Service.

Haveyourtoolservicedbyqualiedpersonaland

repaired only with original spare parts. Than you will be

sure that the safety of the tool is guaranteed.

- 3 -

Loading...

Loading...