22 23

must be performed at the installation site due to possible mis-

handling in shipment, or excessive pressure unknowingly be-

ing applied to the unit. Periodically check the whole system for

leaks, or immediately if the smell of gas is detected.

Before Testing:

Do not smoke while leak testing. Extinguish all open fl ames. Nev-

er leak test with an open fl ame. Make a soap solution of one part

liquid detergent and one part water. You will need a spray bottle,

brush, or rag to apply the solution to the fi ttings. For LP units,

check with a full cylinder. Remove the control knobs and battery

to disable accidental ignition. Open the drawer containing LP or

natural gas hook up, this is where all tests will be performed.

To Test:

Make sure all control valves are in the “OFF” position. Turn the gas

supply “ON”. Check all connections from the supply line, or LP

cylinder up to and including the manifold pipe assembly. Apply

the soap solution around the connection, valve, tubing and end of

the manifold. Soap bubbles will appear where a leak is present. If a

leak is present, immediately turn off gas supply, tighten any leak-

ing connections, turn gas on, and recheck. Check all the gas con-

nections at the base of the control valves where they screw into

the manifold pipe.

If you cannot stop a gas leak, turn off the gas supply and call your

local gas utility or the dealer you purchased the appliance from.

Only those parts recommended by the manufacturer should be

used on the grill. Substitution can void the warranty.

WARNING:

Do not use the grill until all connections have been checked and

do not leak.

Check all gas supply fi ttings for abrasions, cracks and leaks

before each use. It is recommended to keep a spray bottle fi lled

with soapy water near the shutoff valve of the gas supply valve.

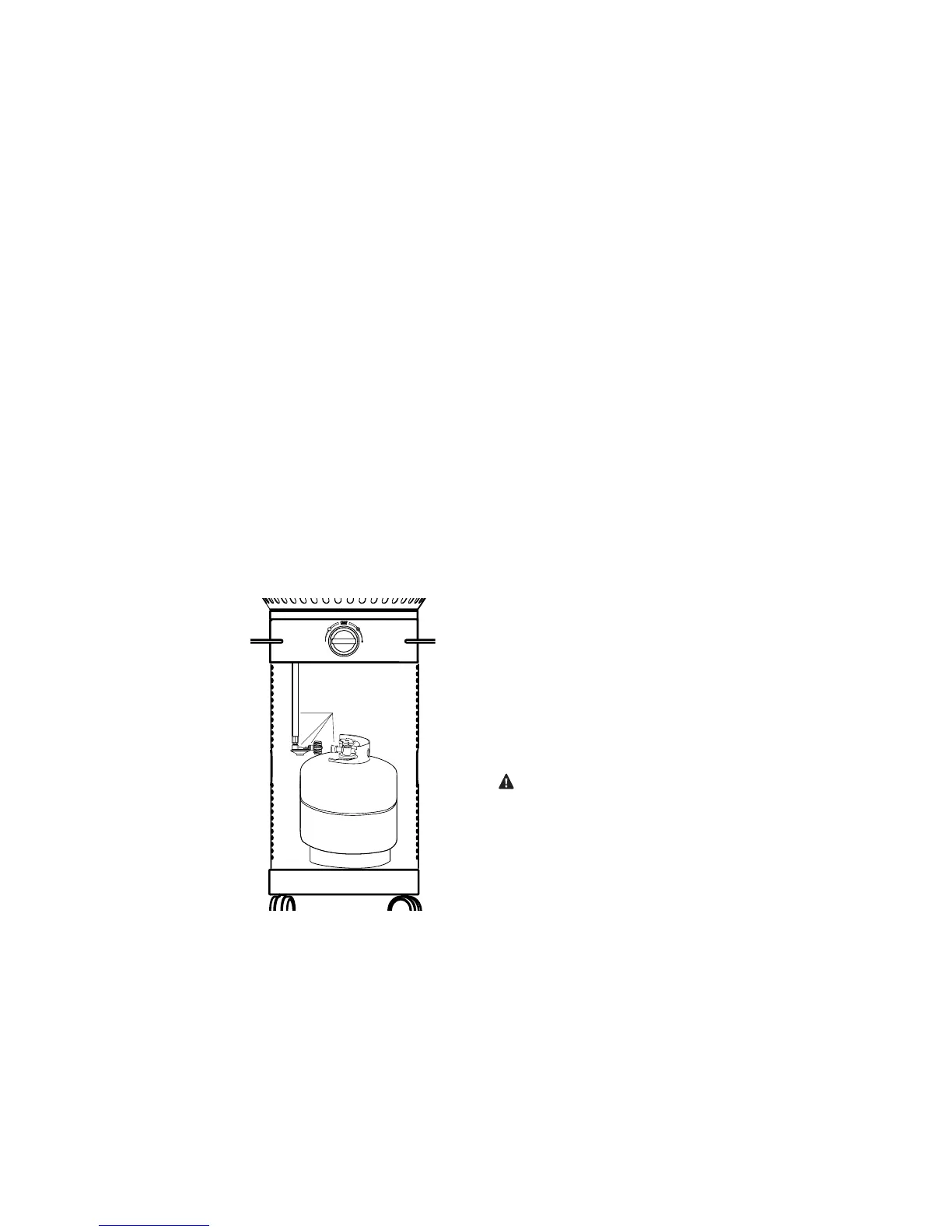

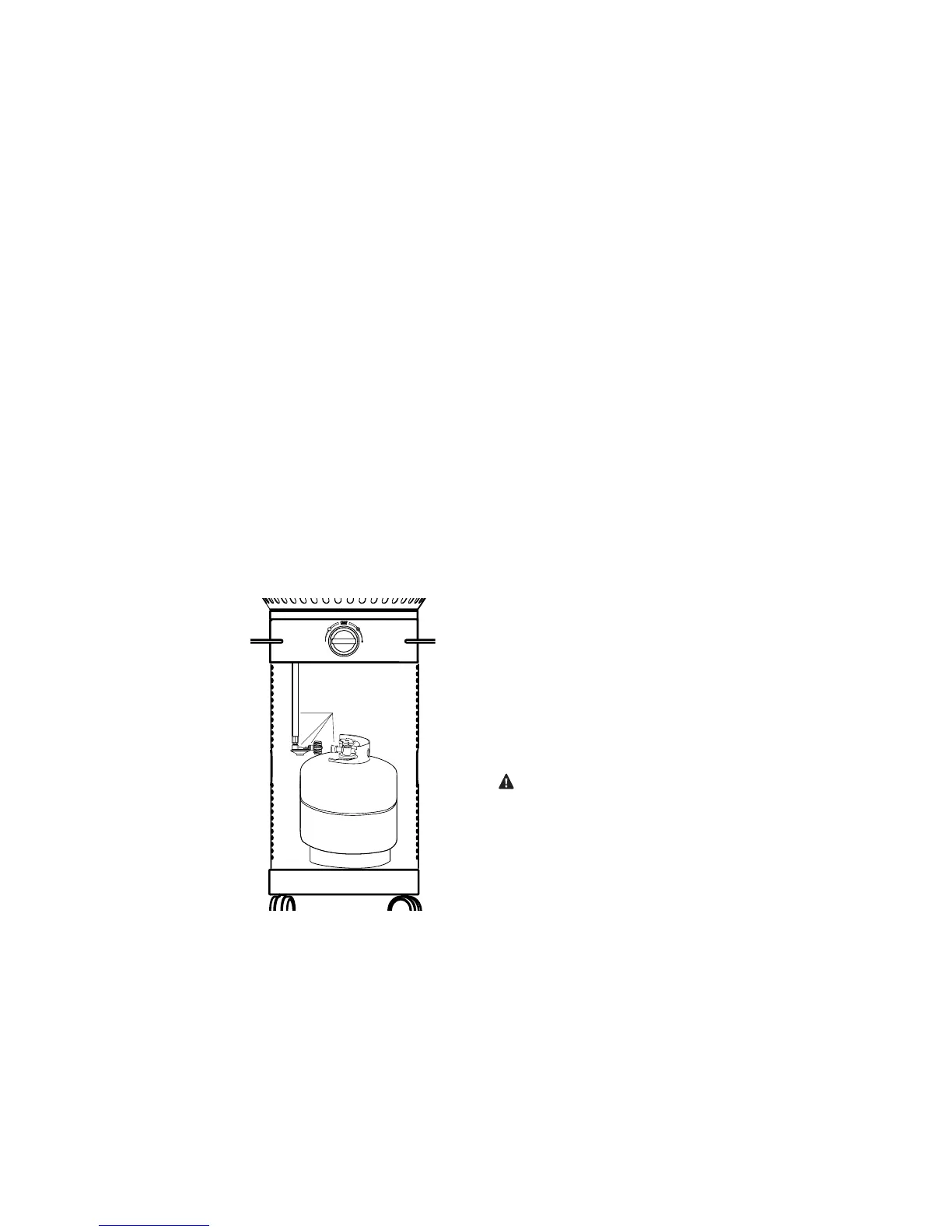

Spray all the fi ttings. Bubbles indicate leaks. (FIG. 02)

already done so when disengaged. Your local LP fi lling station

should be equipped with the proper equipment to fi ll your tank.

Lp Tank Requirements:

A dented or rust LP tank may be hazardous and should be

checked by your local supplier. Never use a cylinder with a dam-

aged valve. Always check for leaks after every LP tank change. The

LP gas cylinder must be constructed and market in accordance

with specifi cations for LP gas cylinders of the U.S. Department

of Transportation (DOT or CAN/CSA-B339) and designed for use

with a Type 1 system only. Do not change the regulator and hose

assembly from that supplied with the unit or attempt to use a

Type 1 equipped regulator and hose assembly with a standard 510

POL tank/valve assembly. The cylinder must be provided with a

shut-off valve terminating in an LP gas supply cylinder valve outlet

specifi ed, as applicable, for connection Type 1. If the appliance is

stored indoors, the cylinder must be disconnected and removed

from the appliance. Cylinders

must be stored outdoors in a

well-ventilated area out of the

reach of children.

Note: When an LP unit is di-

rectly attached into an LP house

system, the step down regula-

tor MUST be used to reduce the

supply pressure to a max. 14”

W.C. and a min. 11” W.C. to the

grill regulator.

Leak Testing

General:

Although all gas connections

on the grill are leak tested at

the factory prior to shipment, a

complete gas tightness check

Leak Test Spots

Check for

abrasions, cracks

and leaks

FIG. 02

Loading...

Loading...