PROTECTIVE :VINYL

This adhesive vinyl (included inside the packing) protects the instruments against

water drippings, as in commercial refrigerators, for example. Do the application after

finishing the electrical connections.

Remove the protective paper

and apply the vinyl on the entire

superior part of the device,

folding the flaps as indicated by

the arrows.

72 mm

Dimension of the clipping

for setting of the instrument

in panel

29 mm

®

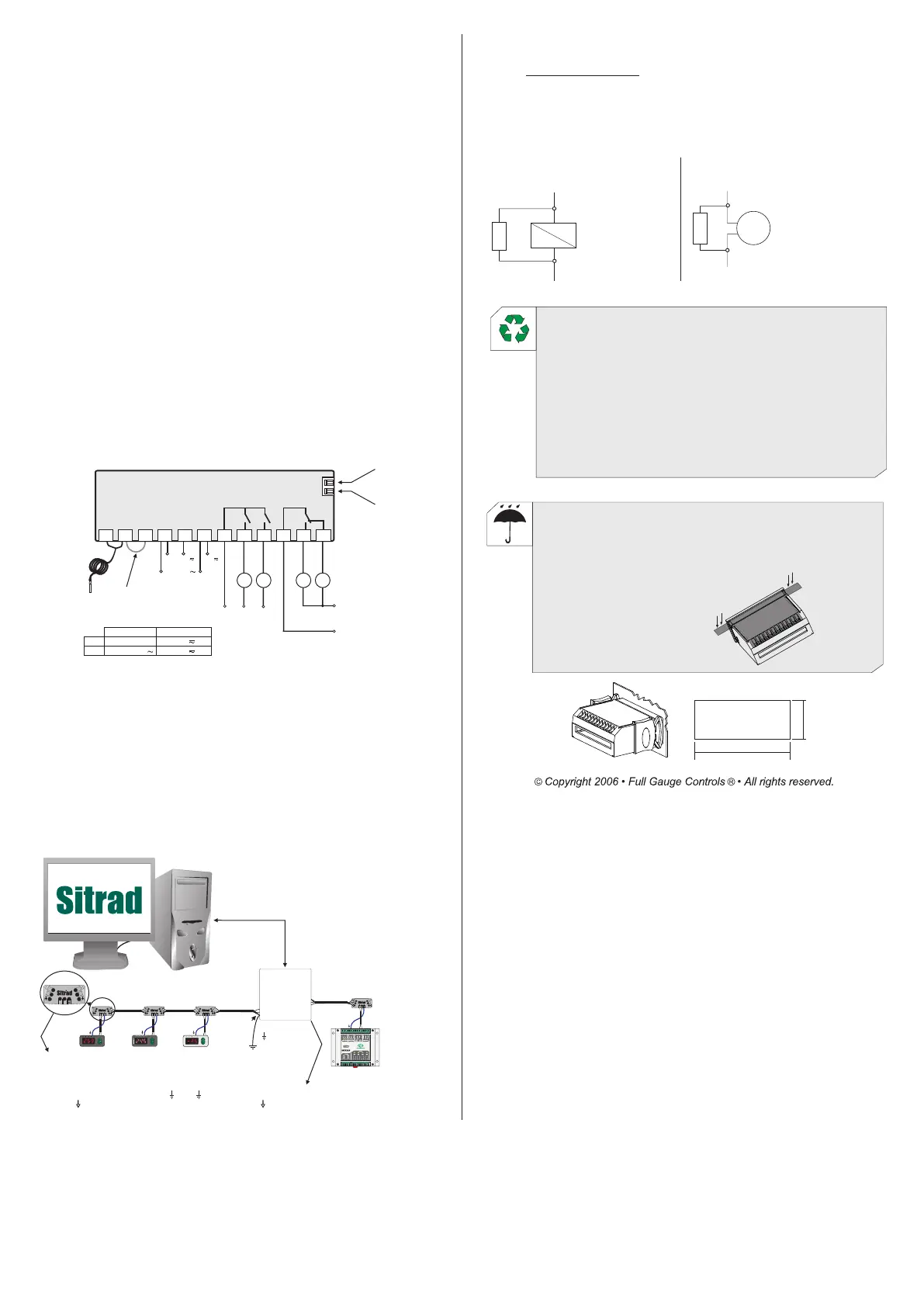

12 - INTEGRATING CONTROLLERS, RS-485 SERIAL INTERFACE AND

COMPUTER

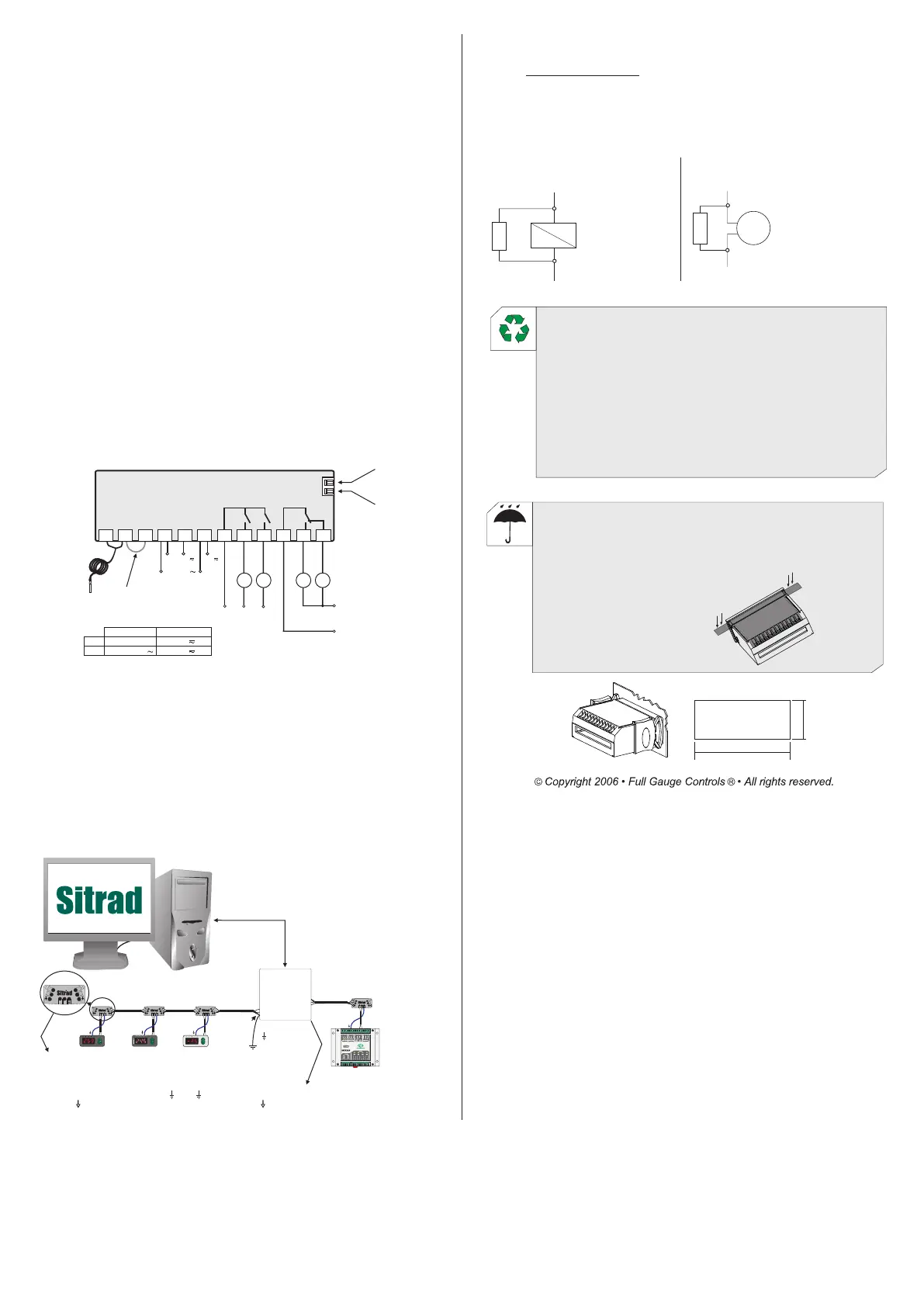

11 - WIRING DIAGRAM

ENVIRONMENTAL INFORMATION

Package:

The packages material are 100% recyclable. Just dispose it through specialized

recyclers.

Products:

The electro components of Full Gauge controllers can be recycled or reused if it is

disassembled for specialized companies.

Disposal:

Do not burn or throw in domestic garbage the controllers which have reached the end-of-

life. Observe the respectively law in your region concerning the environmental

responsible manner of dispose its devices. In case of any doubts, contact Full Gauge

controls for assistance.

10.3 - Data recording in the event of a power outage

With the battery connected, as described in item 10.1 and the datalogger activated, the

MT-543Ri LOG will record the temperature in the internal memory even in the event of a

power outage. These records can be configured to be recorded at preset time intervals (F37)

and/or with the temperature variation (F38). If the temperature variation data record is disabled,

the device will read the temperature sensor only at the set time intervals, therefore using less

energy. With the temperature change recording activated, the sensor will be constantly read,

using more energy, but recording all the details of the temperature variation.

10.4 - Battery Precautions

- Avoid unnecessarily draining the battery;

- If the appliance is not in use, the battery should be disconnected;

- If a greater time interval between each sample is set, the datalogger will use less battery power;

- If not required, disable the F38 function to avoid wasting the energy used in reading the

temperature sensor.

OUT 1

OUT 2

C2

C1

COMMON OUT 1 AND 2

OUT 3 NO

OUT 3 NC

C3B

C3A

Loads

supply

C3A and C3B

S1

(black)

Sensor

4

5

6

7

8

9

10

11

12

321 21

Serial communication

RS-485

Digital input

A B

COMMON OUT 3

Loads

supply

C1 and C2

Power

supply

IMPORTANT

According to the chapters of norm IEC 60364:

1: Install protector against overvoltage on the power supply

2: Sensor cables and signal cables of the computer may be joined, but not in the same electric conduit

through which the electric input and the activation of the loads run

3: Install transient suppresors (RC filters) parallel to the loads as to increase the product life of the

relays.

Schematic for the connection of supresors

to contactors

Suppresor

A1

A2

A1 and A2 are the

contactor coil terminals.

Schematic for the connection of supresors to

direct activation loads

Load

Suppresor

For direct activation the maximum

specified current should be taken

into consideration.

A B

RS-485 Network

RS-485 Serial Interface

®

Device used to establish the

connection Full Gauge Controls’

instruments with the Sitrad .

Instrument

RS-485 Network

External

mesh

A

B

A

A

B B

A

B

A

A

B B

A

B

A

A

B B

A

B

A

B

A

B

A

A

B B

A

B

Serial interface

RS-485

Full Gauge

MOD 64

A

A

B B

A

B

terminal

grounded

Distribution Box

Used to connect more than one instrument to the Interface. The wire's connections must

be made in agreement with the following rules: terminal A of the instrument connects to

the terminal A of the distribution box, that must be connected with the terminal A of the

Interface. Repeat the action for terminals B and , being the cable shield.

The terminal of distribution box must be connected to the respective terminals of

each instrument.

Battery

connection (*)

Above specified current use

a contactor.

Note 1: Sensor cable length can be increased by the user until 200 meters, using 2 x 24 AWG cable. For

immersion in water use thermometric well.

(*) The MT-543Ri LOG comes with an internal battery disconnected for storage. Before installing

the instrument, connect it to the terminals 2 and 3 through a wire, as shown.

Note 2: After connecting the terminals as indicated, keep the instrument powered on for at least

ten hours for battery charging.

4 - 5

4 - 6

12V

24V

MT-543Ri LOG

-

90 ~ 264V

MT-543RiL LOG

0

(12V ) (24V )

90 ~ 264V

10 - INTERNAL BATTERY

10.1 - Battery connection

The MT-543Ri LOG has an internal rechargeable battery. This battery provides the power to

operate the clock and record the data in the memory in the event of a power outage. The device leaves

the factory with the battery disconnected for storage. Before installing the instrument, the battery must

be connected using terminals 2 and 3, using a wire as shown in the wiring diagram.

10.2 - Clock

The MT-543Ri LOG has an internal clock to record data in its memory. To continue operation,

even in the event of a power outage, the battery must be connected as described in item 10.1. If the

battery is disconnected or discharged, when energizing the device, the following message will appear

indicating that the date and time should be set.

PUMP

AUX

1

AUX 2

MICROSOL II plus

OUT

1

OUT 2

OUT 3

PCT-400R plus

OUT 4

ALMR

Loading...

Loading...