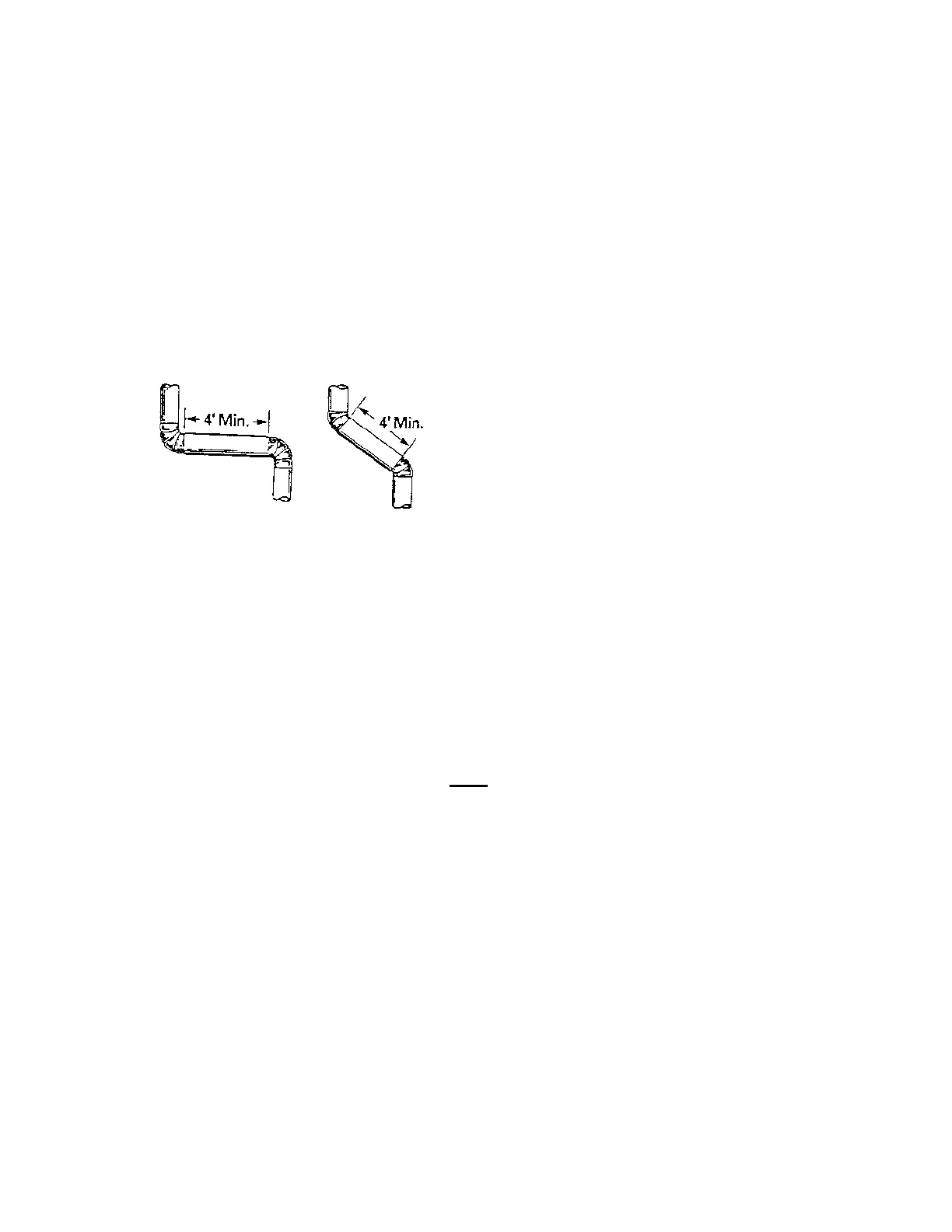

2. Separation of turns in the ductwork

All turns in the exhaust system, external to the dryer itself, including the distance from

the last turn to the dampered wall cap, should be separated by at least 4 feet of straight

metal duct. This requirement will reduce the added resistance to airflow, which results

from rapid changes of airflow direction inside the ducting.

If two turns must be closer than 4’, deduct 10’ from the maximum lengths shown in.

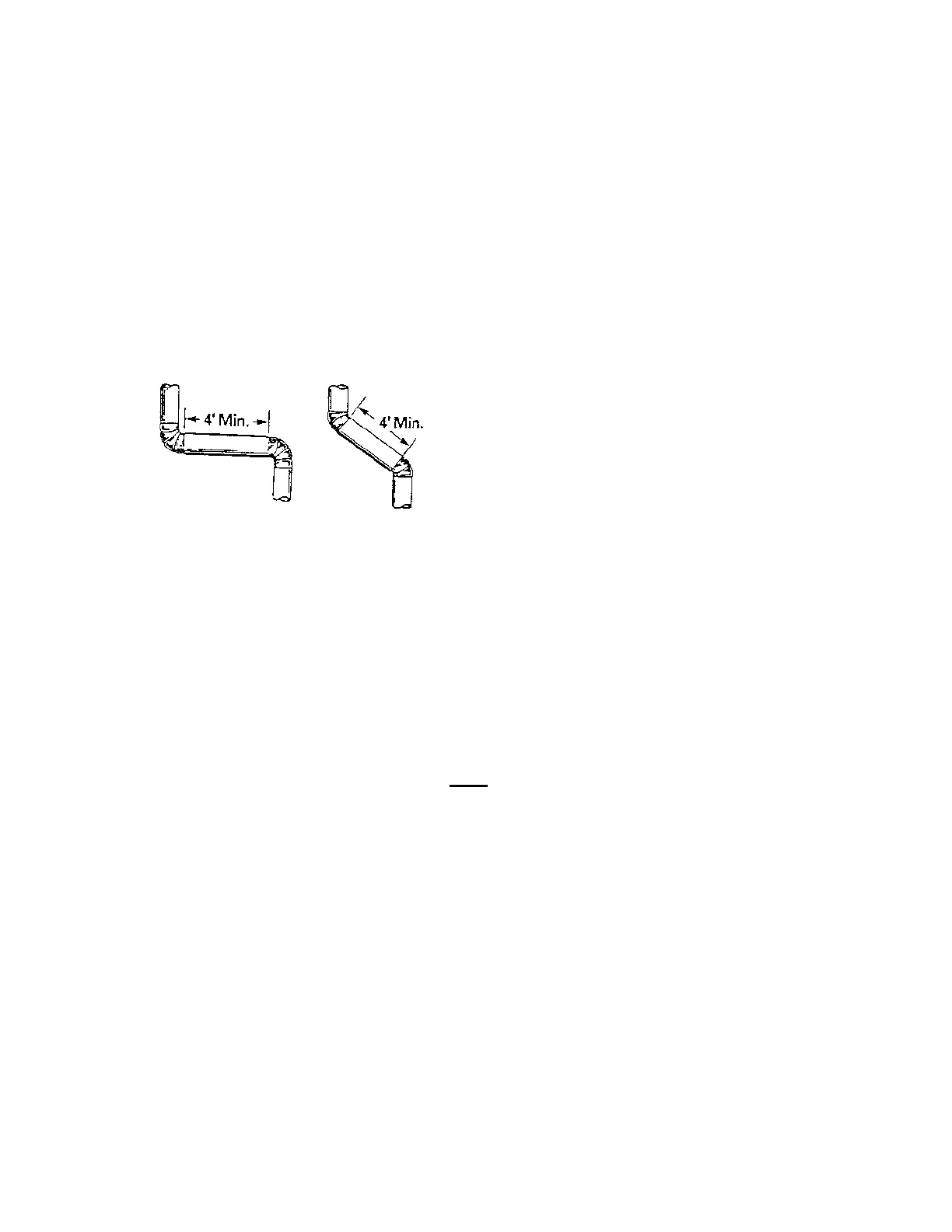

3. Treatment of turns other than 90 degrees

One turn of 45 degrees or less may be ignored. Two such turns should be treated as one

90-degree. Each turn over 45 degree should be treated as one 90 degree. Refer to specific

dryer installation for maximum duct lengths and for allowable 90 degree bend.

Note: Some dryers are limited to only rear exhausting. Consult the installation

instruction for the type of dryer being used.

4. Use of Flexible metal ducting

We recommend the use of 4” diameter rigid metal ducting. Flexible ducting is

susceptible to unforeseen restrictions, turns or kinks. However, if flexible metal

ducting must be used, the following precautions must be adhered to:

a. Use only 4” diameter metallic flexible ducting.

b. Never use foil or other thin ducting that can be easily punctured with a

screwdriver or nail.

c. The flexible duct must not be allowed to collapse, kink or sag when the

dryer is pushed to its final installed position. It is suggested that required

turns in the exhaust system be made with rigid elbows.

d. Minimize ducting length. Don’t exceed the maximum allowable duct

lengh specified in the installation instructions. Account for all bends.

e. To reduce the risk of fire, NEVER USE FLEXIBLE PLASTIC OR

OTHER COMBUSTIBLE DUCTWORK.

Loading...

Loading...