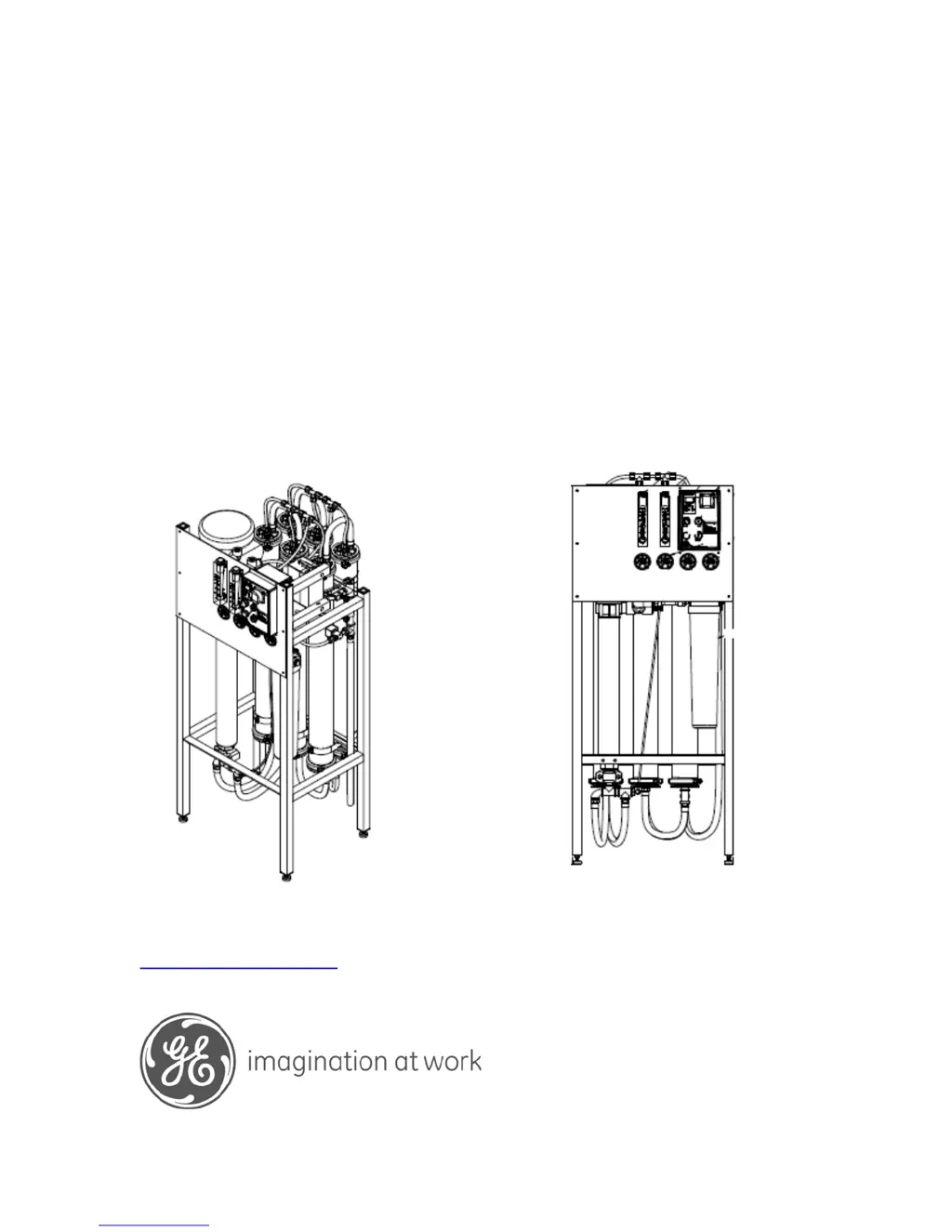

Why is my GE Water Filtration System's operating pressure high?

- TThomas OrozcoAug 16, 2025

High operating pressure in your GE Water Filtration System can occur due to several reasons. The recycle or concentrate lines might be plugged, which requires disassembling the plumbing to the recycle orifice to remove any foreign particles. The pressure gauge could be inaccurate, needing replacement or calibration. Ensure that the service and CIP valves are not closed simultaneously, verifying that the water path to both is open. A restricted or reduced permeate flow rate can also cause high operating pressure; refer to the causes for low permeate flow rate to resolve this.