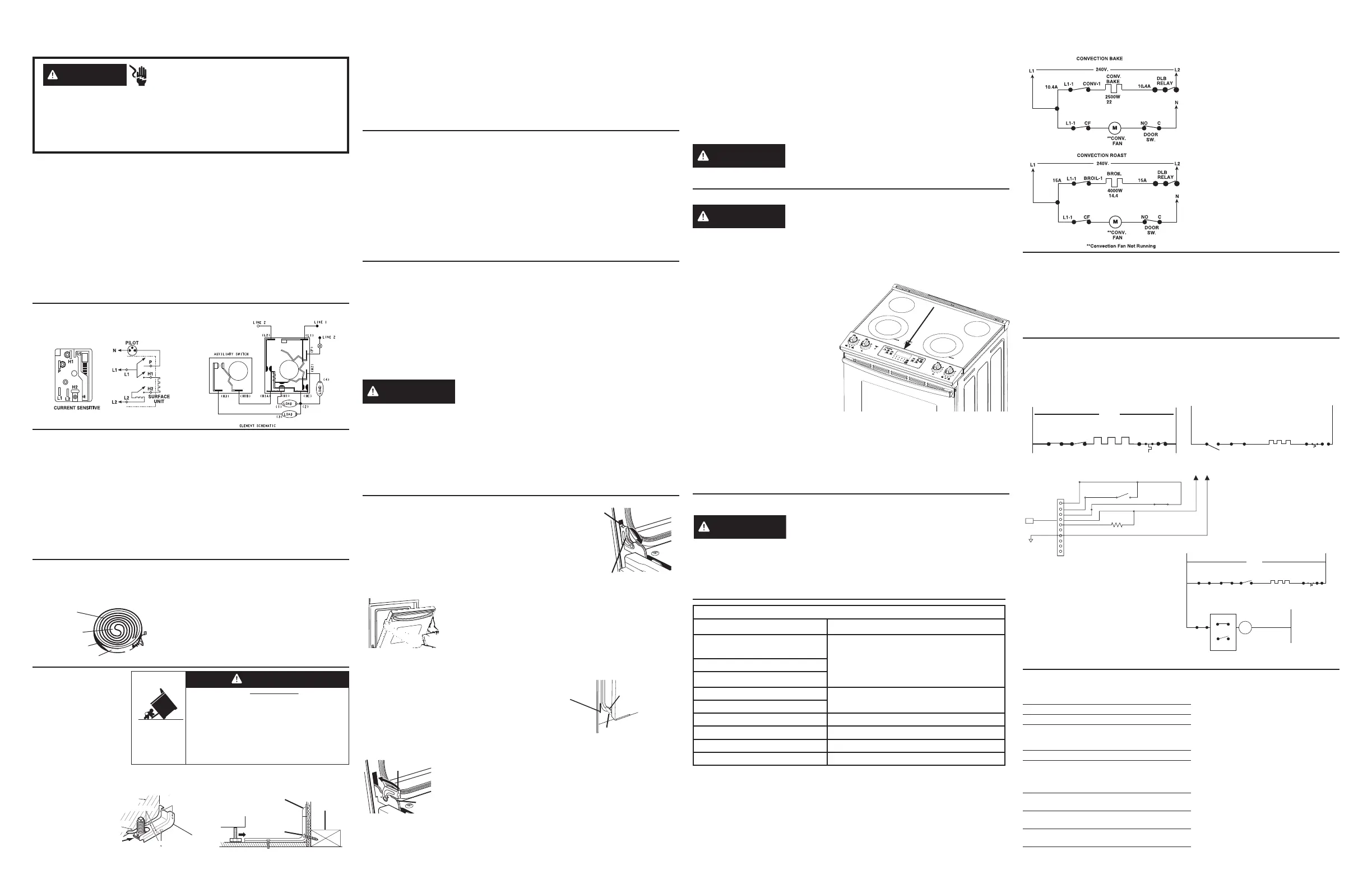

30” RADIANT SLIDE-IN CONVECTION RANGE

SURFACE UNIT SWITCHES

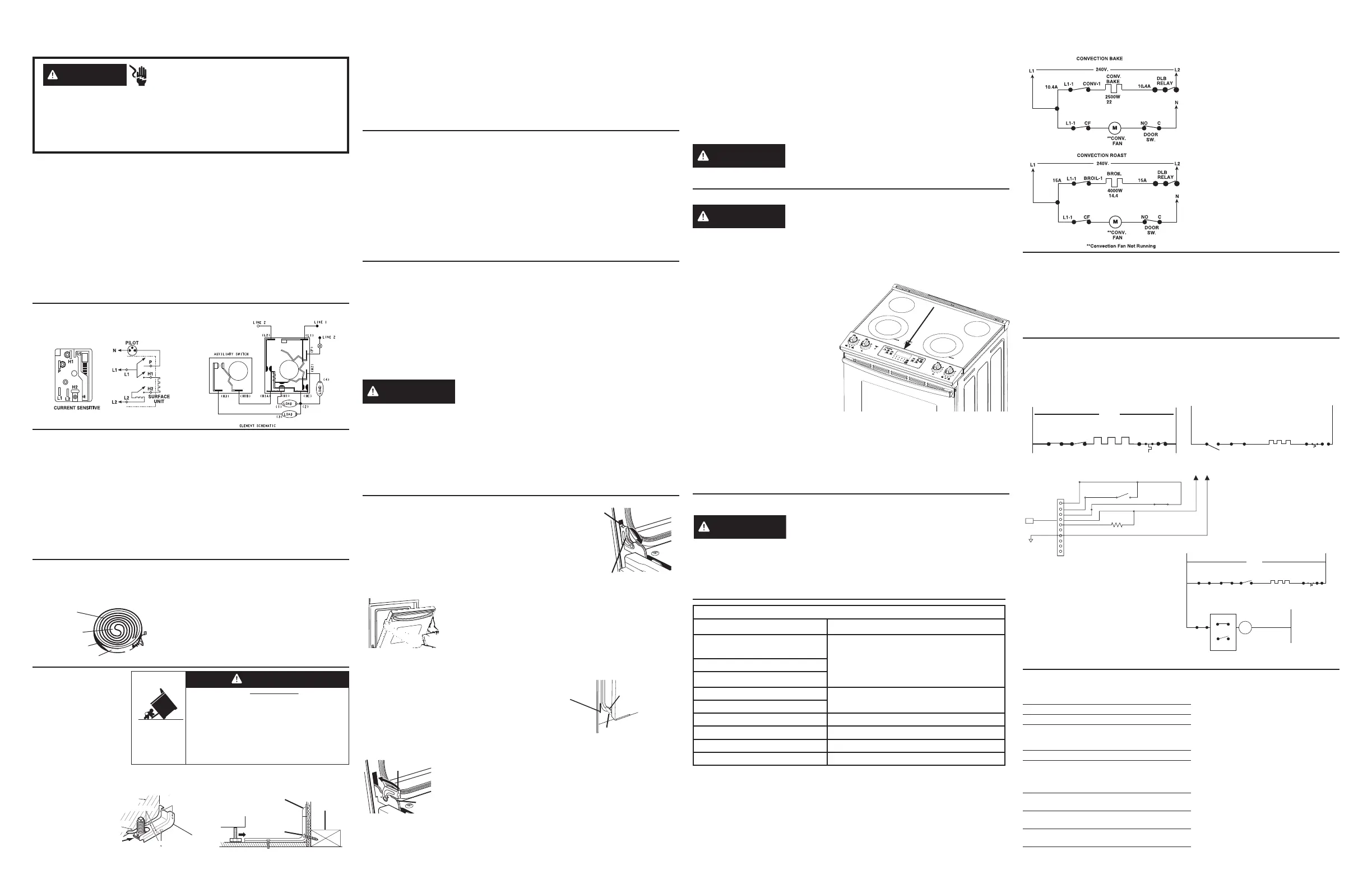

RADIANT HEATING ELEMENT SYSTEMS

Heating Elements: The radiant heating element consists of a resistance

ULEERQDWWDFKHGWRPLFURSRURXVLQVXODWLRQZLWKPROGHGFHUDPLF¿EHUZDOOVLQ

a corrosion-protected metal tray.

The Heating Elements come in four sizes:

• 6” – 240 Volt, 1200 Watts

• 9”/6” – 240 Volt, 3100 Watts

• 12”/9” – 240 Volt, 3000 Watts

• Warmer – 240 Volt, 120 Watts

CONTROL PANEL ASSEMBLY

5HSODFLQJ,Q¿QLWH6ZLWFKHV

1. Remove the two screws holding the

LQ¿QLWHVZLWFK

2. Remove steel control panel insert by

UHPRYLQJVFUHZV

3. From the rear of the control panel

assembly, unplug wires and remove

LQ¿QLWHVZLWFK

4. Repeat steps in reverse order to

UHDVVHPEOHWKHXQLW

Removing Faceplate

1.7XUQWKHSRZHURႇWRWKHXQLW

2.5HPRYHDOONQREV

3. Unscrew all faceplate retainers while

holding the faceplate against the

FRQWUROWULP7KHUHWDLQHUVPXVWRQO\

EHKDQGWLJKWHQHG

4. Move the faceplate 3 inches away

from the control panel and unplug the

KDUQHVVIURPWKHSDQHO

5. Repeat steps in reverse order to

UHDVVHPEOHWKHXQLW

NOTE: Installation

information is for reference

only. See Installation

Instructions shipped with

the product for complete

details and before

attempting to install.

Bracket should be

DWWDFKHGWRWKHÀRRURUZDOO

to hold either the right or

left rear leveling leg. Make

sure the leveling leg re-engages the bracket when the range is moved for any reason.

TEMPERATURE LIMIT/HOT LIGHT SWITCH

The Temperature Limit/Hot Light Switch performs two functions:

1. Turns on HOT LIGHT DVVRRQDVJODVVWHPSHUDWXUHUHDFKHV)7KHHOT LIGHT

will remain on until the glass surface above the heating unit has cooled below 150°F

HYHQDIWHUVXUIDFHXQLWVZLWFKKDVEHHQWXUQHGRႇ

2. Detects when glass temperature above a unit has exceeded its limit of approximately

)DQGGLVFRQQHFWVSRZHUWRWKDWXQLW:KHQJODVVWHPSHUDWXUHFRROVEHORZ

)WKHXQLWZLOOWXUQEDFNRQ

The Temperature Limit/Hot Light Switch cannot be calibrated.

REMOVABLE OVEN DOOR

COMPONENT COMPARTMENT AIRFLOW

The oven uses a fan for cooling the components. Air is pulled in by the fan blades

and circulated in the component compartment. The air is exhausted through

louvers below the control panel and out the slots above the door.

DOOR ASSEMBLIES:

The doors can be separated into two assemblies: (1) Outer assembly which

consists of handle, vent trim, outer glass, bottom trim and frame; (2) Inner

assembly which consists of inner panel, gasket, glass panels and insulation.

The assemblies are held together by 2 screws on each side, along with 4 screws

across the bottom.

CAUTION

Care must be taken when mounting door handle not to

overtighten handle screws. Overtightening screws can damage handle. Hand-

WLJKWHQVFUHZVGRQRWXVHHOHFWULFGULYHU0DNHVXUHKDQGOH¿WVVQXJJO\WRGRRU

panel.

SELF-CLEAN DOOR GASKET: The door gasket is attached to the inner door panel

E\DFKDLQRIVSULQJFOLSV

1. /RFDWHVSULQJFOLSDWFHQWHURIJDVNHWDQGLQVHUWLQKROHRQLQQHUGRRUSDQHOQHDUWRS

2. ,QVWDOOJDVNHWE\EHQGLQJDWEHVLGHFOLSDQGURFNLQJLQWRKROH

3. 7XFNORRVHHQGVLQWRVORWDWWKHERWWRPRILQQHUSDQHO

REMOVABLE OVEN DOOR

The door is very heavy. Be careful when removing

and lifting the door. Do not lift the door by the handle.

To Remove:

1. )XOO\RSHQWKHGRRU

2. Push the hinge locks down toward the door frame,

WRWKHXQORFNHGSRVLWLRQ$WRROVXFKDVDVPDOO

ÀDWEODGHVFUHZGULYHUPD\EHUHTXLUHG

3.)LUPO\JUDVSERWKVLGHVRIWKHGRRUDWWKHWRS

To Replace:

1. Firmly grasp both sides of the door at

WKHWRS

2. With the door at the same angle as the

removal position, seat the indentation of

the hinge arm into the bottom edge of the

KLQJHVORW7KHQRWFKLQWKHKLQJHDUPPXVW

EHIXOO\VHDWHGLQWRWKHERWWRPRIWKHVORW

Removal position

Push hinge locks up to lock

3. )XOO\RSHQWKHGRRU,IWKHGRRUZLOOQRWIXOO\RSHQ

the indentation is not seated correctly in the bot-

WRPHGJHRIWKHVORW

4. Push the hinge locks up against the front frame of

WKHRYHQFDYLW\WRWKHORFNHGSRVLWLRQ

5. &ORVHWKHRYHQGRRU

4. Close door to the door removal position, which is halfway

EHWZHHQWKHEURLOVWRSSRVLWLRQDQGIXOO\FORVHG

5./LIWGRRUXSXQWLOWKHKLQJHDUPLVFOHDURIWKHVORW

Bottom Edge

of Slot

Hinge Arm

Indentation

Hinge Arm

Screw Must

Enter Wood or

Metal

Anti-Tip Bracket

Attachment to Wall or Floor

Hinge

Lock

Wall

Plate

Adjacent Cabinet or Final

Location of Range Side Panel

Wood Floor Holes

Anti-Tip Bracket Side

Rear Leveling

Leg of Range

Concrete Floor Holes

Wall Holes

Slot

Hinge Lock

Pull hinge locks down to unlock

OVEN SENSOR AND DOOR SWITCH OHMMETER TEST

(See “Motorized Door Lock Operation” for door switch function explanation.)

Remove power from oven. Make resistance measurement from side of sensor

and lock switch connector, with exposed terminals disconnected from

control.

**If convection fan is not working,

make the following checks:

• Check the voltage from terminal CF

to N on control—it should read 120V

in Conv Bake or Roast mode. If not,

replace the control.

• If voltage is OK, check the

convection fan motor. It reads

approximately 15–20 at room

temperature. Check to make sure the

fan shaft is not rubbing on the oven

liner.

Heating Element

Micro Porous

Insulation

Ceramic Fiber

Molded Walls

Metal Tray

SH. 1 of 4 31-17264

WARNING

Electrical Shock Hazard

'HDWKRUVHULRXVLQMXU\FDQUHVXOWIURPIDLOXUHWRIROORZWKHVHLQVWUXFWLRQV

6HUYLFHE\DTXDOL¿HGVHUYLFHWHFKQLFLDQRQO\

'LVFRQQHFWSRZHUEHIRUHVHUYLFLQJWKLVSURGXFW

5HFRQQHFWDOOJURXQGLQJGHYLFHVDIWHUVHUYLFH

5HSODFHDOOSDUWVDQGSDQHOVEHIRUHRSHUDWLQJ

A child or adult can tip the range and be killed.

Verify the anti-tip bracket has been properly

installed and engaged.

Ensure the anti-tip bracket is re-engaged when

the range is moved.

Do not operate the range without the anti-tip bracket

in place and engaged.

Failure to follow these instructions can result in

death or serious burns to children or adults.

Tip-Over Hazard

WARNING

CONTROL PANEL ASSEMBLY AND REMOVAL

The control panel contains the Main Logic Board, burner cooktop touch boards and

RYHQWRXFKERDUG

To service:

5HPRYHWKHVFUHZVIURPVLGHVHFXULQJWKHFRQWUROSDQHODVVHPEO\WRWKH

FRQWUROHQFORVXUH

/LIWWKHSDQHODQGGLVFRQQHFWWKHZLULQJKDUQHVVWRUHPRYH

/D\WKHSDQHODVVHPEO\RQWKHFRRNLQJVXUIDFH

5HYHUVHWKHSURFHVVWRLQVWDOO

WARNING

3ODFHDSURWHFWLYHFRYHULQJVXFKDVDWRZHOEHWZHHQWKH

FRQWUROSDQHODQGWKHFRRNLQJVXUIDFHWRDYRLGGDPDJHWRWKHFRQWUROSDQHO

COOKTOP REMOVAL

CAUTION

5DLVLQJWKHFRRNWRSWRRKLJKFDQEUHDNWKHJODVV

To Remove:

1.'LVFRQQHFWWKHSRZHU

2.5HPRYHWKHVFUHZVIURPVLGHVVHFXULQJWKHFRQWUROSDQHODVVHPEO\WRWKH

SODVWLFORZHUWULP

3.7RGLVHQJDJHWKHVQDS¿WRIWKHFRQWUROSDQHODVVHPEO\WRWKHSODVWLFORZHUWULPGR

the following:

8VLQJD´SXWW\NQLIH¿UPO\

press the center of the plastic lower

trim at the maintop contact point

towards the control panel assembly

XQWLOLWGLVFRQQHFWV

4. Unplug the wiring connections

that connect to the enclosure and

XQVFUHZWKHJURXQGZLUH

5. Unplug the remaining connections

from the main harness that connects

WRWKHFRQWUROSDQHODVVHPEO\6HW

WKHFRQWUROSDQHODVLGH

6. Remove 6 screws securing the plastic lower trim to the maintop frame and remove

LW

7.5HPRYHVFUHZVVHFXULQJWKHFRQWUROHQFORVXUHWRWKHPDLQWRSIUDPH

8./LIWWKHFRRNWRSDWWKHIURQWDQGSXOOIRUZDUG

9.'LVFRQQHFWWKHZLULQJKDUQHVVDWWKHUHDURIWKHPDLQWRS

5HYHUVHWKHSURFHVVWRUHLQVWDOO

DISCONNECT POWER BEFORE SERVICING

IMPORTANT: Reconnect all grounding devices. All parts of this appliance capable

of conducting electrical current are grounded. If grounding wires, screws, straps,

clips, nuts or washers used to complete a path to ground are removed for service,

they must be returned to their original position and properly fastened.

GROUNDING SPECIFICATIONS

*URXQG3DWK5HVLVWDQFH

0D[

Insulation Resistance 250K

0LQ

INSTALLATION REQUIREMENTS

Power Supply:7KLVDSSOLDQFHPXVWEHVXSSOLHGZLWKSURSHUYROWDJHDQGIUHTXHQF\

and connected to an individual properly grounded branch circuit, protected by a circuit

EUHDNHURUWLPHGHOD\IXVHDVQRWHGRQUDWLQJSODWH:LULQJPXVWFRQIRUPWRWKH1DWLRQDO

(OHFWULFDO&RGHV7KHUDWLQJSODWHLVORFDWHGRQORZHUIURQWIUDPHEHKLQGWKHVWRUDJH

GUDZHU

DUAL CIRCUIT CONTROL

This element has two cooking zones:

• To use the large cooking area, push to turn the control knob clockwise to the

GHVLUHGVHWWLQJ

• To use the small cooking area, push to turn the control knob counterclockwise to the

GHVLUHGVHWWLQJ

When a cooking zone is activated, coils beneath the zone radiate heat through the

JODVVFRRNWRSWRWKHXWHQVLO7KHUHGJORZRIWKHFRLOVZLOOEHYLVLEOHWKURXJKWKHJODVV

,WZLOOWDNHWKHFRRNLQJ]RQHRQWKHJODVVVXUIDFHDIHZPRPHQWVWRKHDWXS7KHFRLO

F\FOHVRQDQGRႇWRPDLQWDLQWKHVHOHFWHGVHWWLQJ

ELECTRONIC OVEN CONTROL

CAUTION

Components are electrically HOT on control when

voltage is connected to oven. The Electronic Oven Control system consists

of the control, key panel, oven sensor, door and lock assembly.

NOTE:7HPSHUDWXUH0RGH6HOHFWLRQQHFHVVDU\IRURSHUDWLRQRI5HOD\FRQWDFWV

VOLTAGE MUST BE PRESENT ACROSS TERMINALS L1 TO N FOR CON-

TROL TO OPERATE.

CONTROL VOLTAGE

Terminals Voltage

%URLO&20SLQWR47+12

SLQ

9$&DOOWKHWLPH

/WR1

/WR1

/WR%$.( 9$&ZKHQFRRNLQJPRGHLVDFWLYHDQG

oven is not calling for heat

L1 to BROIL

-WR1 9$&ZKHQIDQLVWXUQLQJ&&:

-WR1 9$&ZKHQIDQLVWXUQLQJ&:

-WR1 9$&ZKHQOLJKWLVRQ

-WR1 9$&ORFNLQJRUXQORFNLQJ

2YHQOLJKWQRWZRUNLQJ0DNHWKHIROORZLQJFKHFNV

&KHFNRYHQOLJKWEXOE

/LJKWLVWRFRPHRQZKHQGRRULVRSHQHG²FKHFNYROWDJHDFURVVOLJKWVRFNHW

7HUPLQDOVVKRXOGUHDG9$&,IYROWVFKHFNMDPEVZLWFKDQGZLULQJ

• /LJKWLVWRFRPHRQZKHQFRQWUROOLJKWSDGLVSUHVVHGK906VKRXOGFOLFN&KHFN

voltage from

J903

WR16KRXOGUHDG9$&,IYROWVUHSODFHFRQWURO

ELECTRONIC OVEN CONTROL (Cont)

THERMAL CUT-OUTS

THERMAL CUTOUT SWITCH

$RQHVKRWWKHUPDOIXVHLVPRXQWHGWRWKHUHDURIWKHRYHQ7KHVZLWFKZLOO

open the L2 leg of the power to the heating elements in the event of an over-

WHPSHUDWXUHFRQGLWLRQ7KHVZLWFKZLOORSHQZKHQWKHSDQHOLWLVPRXQWHGWR

UHDFKHVDSSUR[LPDWHO\)DQGZLOOQRWUHVHW7KHRYHQZLOOQRWKHDWDIWHUWKH

VZLWFKRSHQVDQGWKHVZLWFKZLOOQHHGWREHUHSODFHG

V

J401

RTD1

Oven Sensor and Lock Switch Connector

10

Door Plunger

YR

YR

Door Lock

MOTOR SWITCH

YR

5 V-Splice

GND

OX

VX

NW

WX

"L1" BLACK

CONV BAKE

L1

"L2" RED

BAKE

RLY

BROIL

RLY

BAKE

2850 W

240 V

TCO

14.2A

DBL

RLY

“L1” BLACK

L1

L1

K902

RLY

DLB

RLY

BROIL RLY BAKE RLY CONV RLY

CONVECTION

CONV FAN

2500 W

10.42 A

TCO

CW

M

N

CCW

240 V

CONVECTION

CONV FAN RLY

“L2” RED

BROIL AND CLEAN UNTIL AFTER 750 F IS REACHED

“L1” BLACK

L1 BR

TCO

16.7 A

BROIL

40000 W

“L2” RED

DLB

RELAY

QTH

RELAY

BROIL

RELAY

CONTROL VOLTAGE

TERMINALS VOLTAGE

L1-N 120VAC ALL THE TIME

L2-N 120 VAC ALL THE TIME

L1-L2 240 VOLTS when oven is not calling for

heat (BAKE, CONV., and BROIL relay

contacts open).

CN600-7-N 120 VOLTS when light is on.

CN600-1-N 120 VOLTS not locking or unlocking, door

closed

CIRCUIT TERMINALS OHMS

2YHQVHQVRU ȍ#5P7HPS

ȍ#)

Door Unlatched 1-2 open

and open 1-3 open

'RRU/DWFKHG ȍ

DQGFORVHG ȍ

*If oven light is not working, make

the following checks:

• Check oven light bulb.

• Light is to come on when door is

opened–check voltage across light

socket terminals; voltage should

read 120 VAC. If 0 volts, check

jamb switch and wiring.

• Light is to come on when control

light pad is pressed. K906 should

click–check voltage from J703-1

to Neutral. Voltage should read

120 VAC. If 0 volts, check oven

light keypad using ohmmeter test.

If keypad is good, replace the

control.

Loading...

Loading...