Pub No. 31-14514

10-06 JR

IMPORTANT

SERVICE

INFORMATION

DO NOT

DISCARD

PGS908

MODEL NUMBER

OVEN CALIBRATION

Testing has shown that this oven has the best cooking performance at a control setting of 350°F

when the AVERAGE center oven temperature is between 350°F and 390°F. Customers may change

the average center oven temperature by ± 35°F to satisfy their own cooking needs.

To change:

• Press and hold BAKE and BROIL pads until “SF” appears in display.

• Press BAKE pad to enter oven calibration mode. “00” appears if oven calibration has not

been changed previously. If oven calibration has been changed previously, a temperature

between ± 35°F will be displayed.

• Press increase or decrease pads to change average oven temperature.

• Press START pad to return to Time of Day.

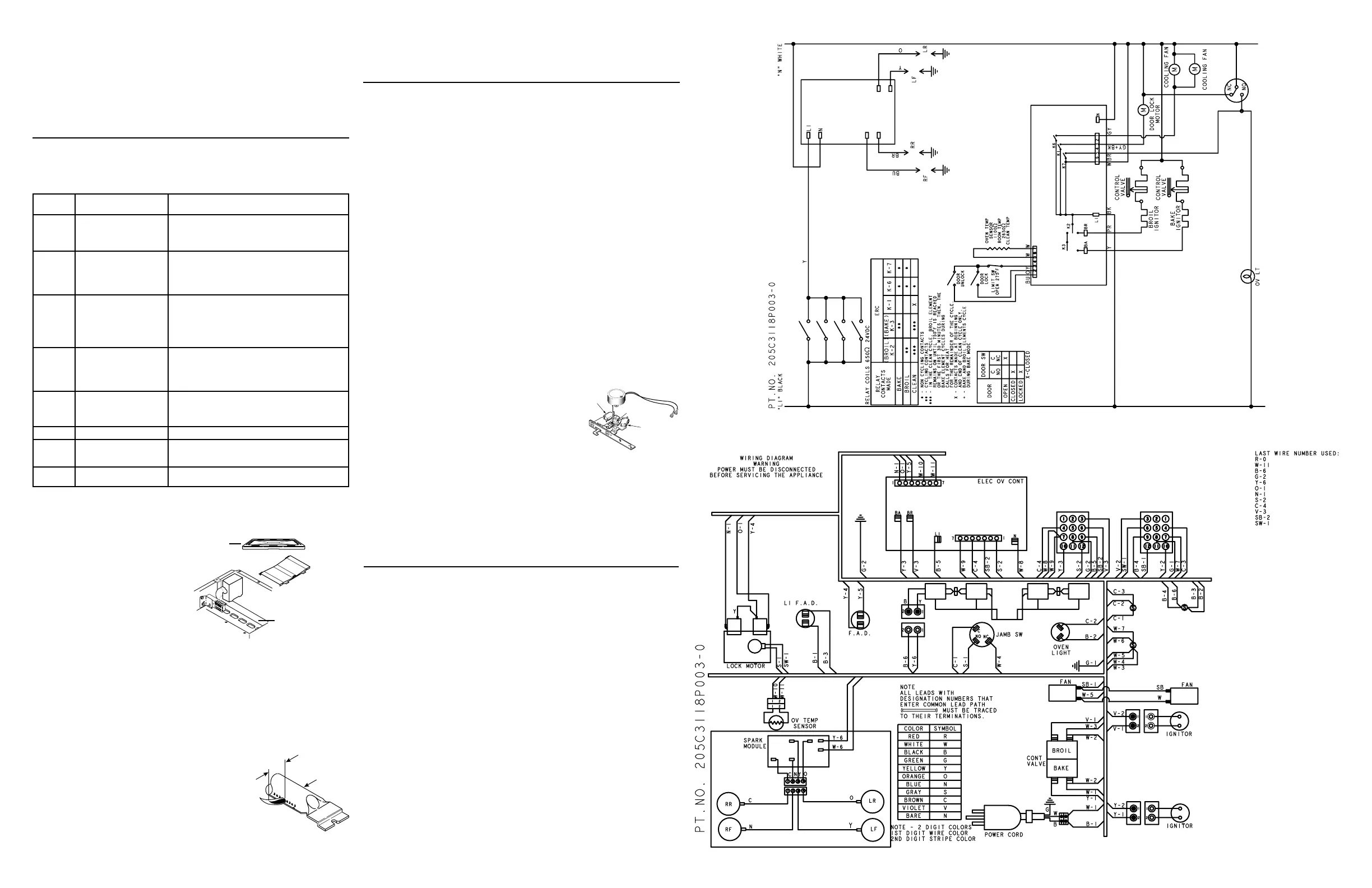

ERC FAILURE CODES

The oven may stop operating but not give an F code on the display immediately. F codes are stored

in nonvolatile eeprom memory until the same fault occurs twice consecutively. After that, the F code

will be displayed. F codes can be recalled by pressing together TIMER, CLOCK, MIN DOWN or 9.

While F codes are displayed, pressing MIN UP or 8 and HR DOWN or 6 together will clear them.

A fault must exist continuously for 5 minutes before an F code is recorded (F2 and F8 are sooner).

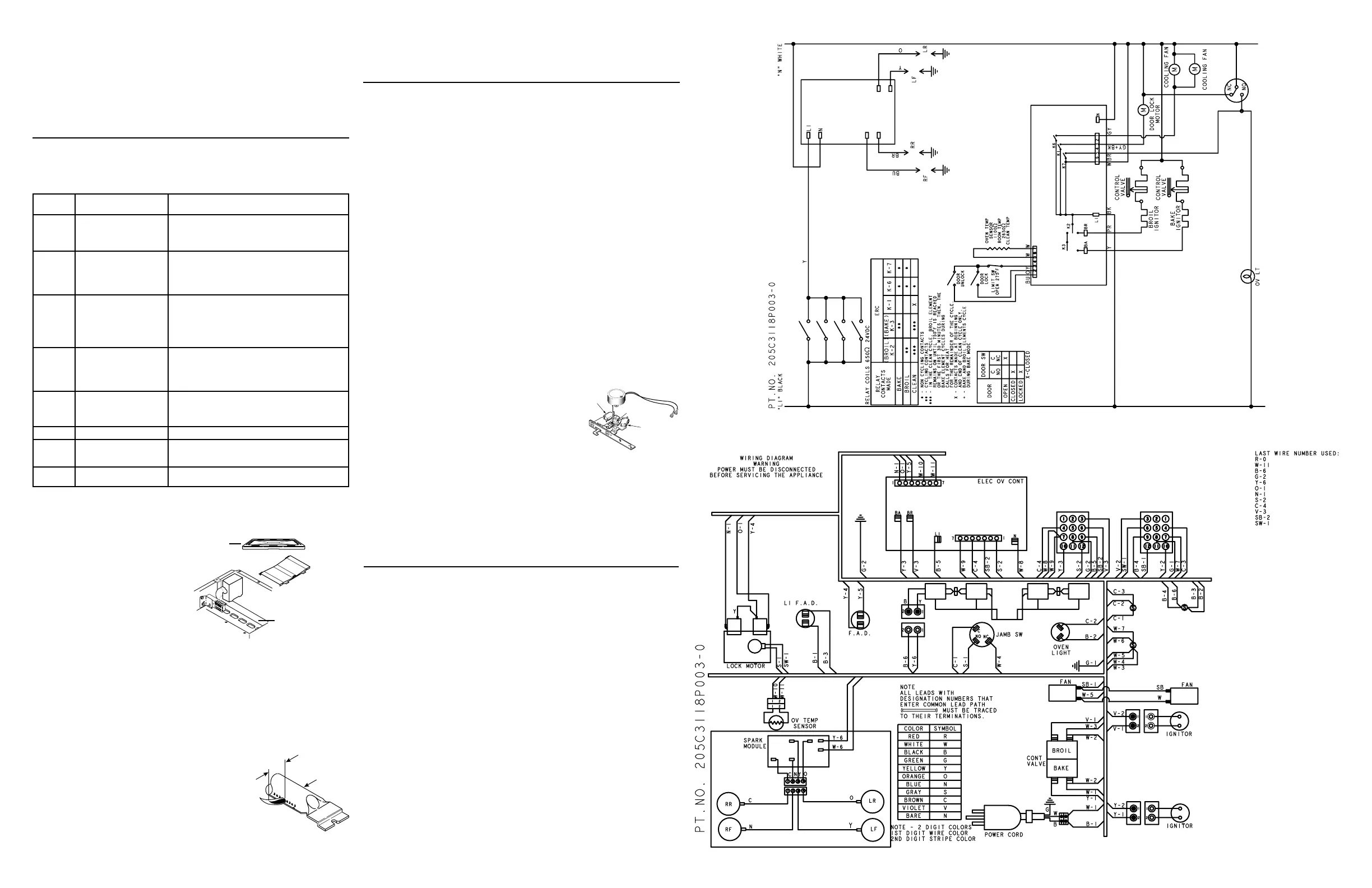

COLD START ODOR ADJUSTMENTS

NOTE: A small amount of odor is normal and will be present when the range is first turned on.

Also, adjustments require disassembly of the burner section. To prevent handling hot parts,

oven should be cool.

STEP 1: Remove oven door, oven

bottom, flame spreader (burner baffle),

orifice cover and oven burner. See below.

STEP 2: Closely Examine the Angle of

the Orifice. The orifice must point straight

into the burner. Check the angle by

looking at the orifice from above and from

the front. A socket Head Nut Driver may

be placed over the maintop orifice to help

determine any out of alignment condition.

The angle can be corrected by using a

small adjustment wrench clamped loosely

over the orifice to bend the orifice and its

mounting assembly as needed. See below.

STEP 3: Inspect the Primary Air Opening. The opening must be clear and free of insulation

all the way down to the metal shield below (0.314 inch opening). See above.

STEP 4: Using a drill bit as a gauge, adjust the air shutter opening.

COLD START ODOR ADJUSTMENTS

STEP 5: Examine the orifice cover. The cover must be as air-tight as possible. Bend the cover

to close off gaps between the sides and the top of the cover.

STEP 6: Install the oven door and observe the burner flame. Before installing the flame spreader

and oven bottom, close the oven door, set the control for BAKE and observe the burner flame.

Note: The door should remain closed during this test.

FLAME

SPREADER

ORIFICE COVER

OVEN BOTTOM

BURNER

FAILURE

CODE MEANING CORRECTION

Shorted OFF key

-F0-

Determine if problem is with key panel or control by

disconnecting ribbon cable and measuring flat cable

pins 13 to 14. Should be open. Should be 100–150

ohms while pressing OFF key.

Over temperature

1. Inside oven cavity as

measured by sensor

over 650°F unlatched

or 915°F latched

• Welded relay contacts

• Cooling fan stalled or blocked

• Airflow to rear of unit

• High resistance in oven sensor leads/connectors

(especially at sensor in rear)

-F3-

Open oven sensor (under

950 ohms)

• Disconnect power. Disconnect sensor harness from

control. Measure sensor resistance (white leads) to

be ~1080 ohms at room temperature with 2 ohms

per degree change.

• Look for damaged harness terminals if not a bad

sensor.

Shorted oven sensor

(over 2900 ohms)

• Disconnect power. Disconnect sensor harness from

control. Measure sensor resistance (white leads) to

be ~1080 ohms at room temperature with 2 ohms

per degree change.

• Separate sensor from harness to determine fault.

Shorted matrix or START

key

Determine if problem is with key panel or control by

disconnecting ribbon cable and measuring flat cable

using pinout chart. Allow up to 1000 ohms when

pressing a key.

-F2-

-F4-

-F7-

EEPROM data shift failure

If repeated, replace control.

Cooling fan or airflow to control area.

Cooling fan stalls while

above 650°F; open thermal

switch in yellow or blue leads

-F8-

-F9-

Loss of latch motor safety

circuit

Replace control.

-FF-

Observe the flames for a period of at least 2 minutes. The flame

should not “lift or blow off” the burner during any period of operation.

It should be blue with approximately a 1/2" to 3/4" inner cone.

LP Gas Installations: If flames lift off the burner and appear

unstable, reduce the air shutter openings an additional 1/32",

cool range and repeat Step 6 from a cold start. If flames are too

large but appear stable, check to be sure the range was properly

converted.

Natural Gas Installations: If flames are too large but appear stable,

tighten the orifice hood to reduce the gas flow to the burner.

1/2" To 3/4"

Inner Cone of Flame

Oven Broiler

Burner

REMOVABLE OVEN DOOR

COMPONENT COMPARTMENT AIRFLOW

The oven uses a fan for cooling the components. Air is pulled in by the fan blades and circulated in

the component compartment. The air is exhausted through louvers below the control panel and out

the slots above the door.

DOOR ASSEMBLIES:

The doors can be separated into two assemblies: (1) Outer assembly which consists of handle, vent

trim, outer glass, bottom trim and frame; (2) Inner assembly which consists of inner panel, gasket,

glass panels and insulation. The assemblies are held together by 2 screws on each side, along with

4 screws across the bottom.

CAUTION: Care must be taken when mounting door handle not to overtighten handle screws.

Overtightening screws can damage handle. Hand-tighten screws (do not use electric driver).

Make sure handle fits snugly to door panel.

SELF-CLEAN DOOR GASKET: The door gasket is attached to the inner door panel by a chain of

spring clips.

1. Locate spring clip at center of gasket and insert in hole on inner door panel near top.

2. Install gasket by bending at 90° beside clip and rocking into hole.

3. Tuck loose ends into slot at the bottom of inner panel.

STEP 7: Examine Flame Spreader for signs of warpage. If warped, spreader will have to be

replaced.

STEP 8: Install Flame Spreader and Oven Bottom. With customer present, test range from a cold

start to be sure odor problem has been corrected.

SELF-CLEAN & MOTORIZED DOOR LOCK

OPERATION LOCK CIRCUITS

There are two circuits controlling the locking and unlocking of the door. These are the lock motor

circuit and the lock switch circuit.

The lock motor circuit applies voltage (120 VAC) to the lock motor. This circuit is from L, through

the door switch, lock relay, lock motor to neutral. For this circuit to be complete, the lock relay must

be energized by the “B” control and the door must be closed. An open oven door results in “LOCK

DOOR” flashing in the display after the control has been programmed for clean and “START” has

been depressed.

The lock switch circuit “tells” the control if the lock motor is in the unlocked or locked position or

somewhere in between. There are two lock switches mounted to and operated by the lock motor.

The lock switch circuit is from the “B” control, through one of the lock switches (switch 2 for

unlocked or switch 1 for locked) back to the “B” control. If neither switch is closed, and the oven

temperature is below 600 degrees, the “B” control will energize the lock motor circuit until the correct

switch closes to complete the circuit. (If circuit to the correct switch is open, lock motor will run

continuously with the oven below 600 degrees.)

CLEAN CYCLE AND LOCK SEQUENCE

1. Program the Clean Cycle:

• Press “SELF-CLEAN” pad. 4 hours (4:00) appears on the time display. (Cleaning time can

be changed from the 4-hour starting point by pressing the “SELF-CLEAN” pad a second time.

• After “START” has been pressed, the word “ON” illuminates in red to indicate the cycle

has begun.

2. Locking the Door:

• After programming the clean cycle and pressing START pad, the control energizes the lock

relay. Voltage (120 VAC) is applied to the lock motor circuit. Oven door must be closed before

lock motor can run. “LOCK DOOR” will flash and control will beep until the door is closed.

• The lock motor begins to revolve and turns a cam mounted to the motor shaft.

• The words “LOCKED DOOR” will flash on and off on the display while the lock motor

is in motion.

• As the cam revolves about 1/2 revolution (approximately 12 seconds), it has moved the

lock “hook” into a corresponding slot in the oven door which secures the door.

• The movement of the cam has also closed lock switch 1 which “tells” the control the door is

locked. The control then removes power from the lock motor

circuit by de-energizing the lock relay.

• The lock motor stops and lock switch 1 is held closed by the

cam through the clean cycle.

• The words “LOCKED DOOR” stop flashing and remain

illuminated in the display.

• The word “ON” illuminates in the display.

3. During the Clean Cycle:

• The BROIL relay closes (audible “click”) and the broil burner

begins to heat. The broil burner only will operate during the first 30 minutes of the clean cycle

followed by the bake burner only during the remaining time.

• As the clean cycle progresses and the temperature of the oven control area rises, the cooling fan

is activated.

• A normally closed thermal switch is mounted on a bracket in front of the cooling fan. This switch

is in the lock switch circuit and will open the lock switch circuit in the event of an over-temperature

condition in the control area (caused by a stalled fan, fan switch failure or similar condition).

An -F2- (over-temperature) failure code will appear on the control if this switch opens while the

oven is above 600 degrees. With the oven between 400 to 600 degrees, the clean cycle will be

cancelled by the opening of the switch and the control will revert back to the time-of-day mode.

Below 400 degrees, the lock motor will revolve continuously and the words “LOCKED DOOR”

will flash on the control until the circuit is reestablished.

• The oven will cycle to maintain an average clean temperature of 840°F.

HTI

HTI Tech & Ind

HTSYG048B002FL45

-0001

Date:

Made in China

LOCK SW.

N.O. CONTACT

CLOSED

UNLOCK SW.

N.O. CONTACT

OPEN

CAM IN

LOCK POSITION

LOCKED

229C4059P559

Loading...

Loading...