Flying Shear for Roll Forming machines – Instruction manual Pag. 14 / 29

Suppose we have a cutting system with these specifications:

• The carriage advances 36 mm per motor revolution.

• The encoder on the carriage motor has 1024 ppr.

• The advancement of the metric wheel on the material is 314 mm.

In this case, an encoder with 8192 ppr is suitable.

4.2.3.2 Configuration with 2 Encoders

Enter the encoder data in the ENCODER CONFIG. menu.

Table 3 shows the encoder configurations to be used with 2 encoders..

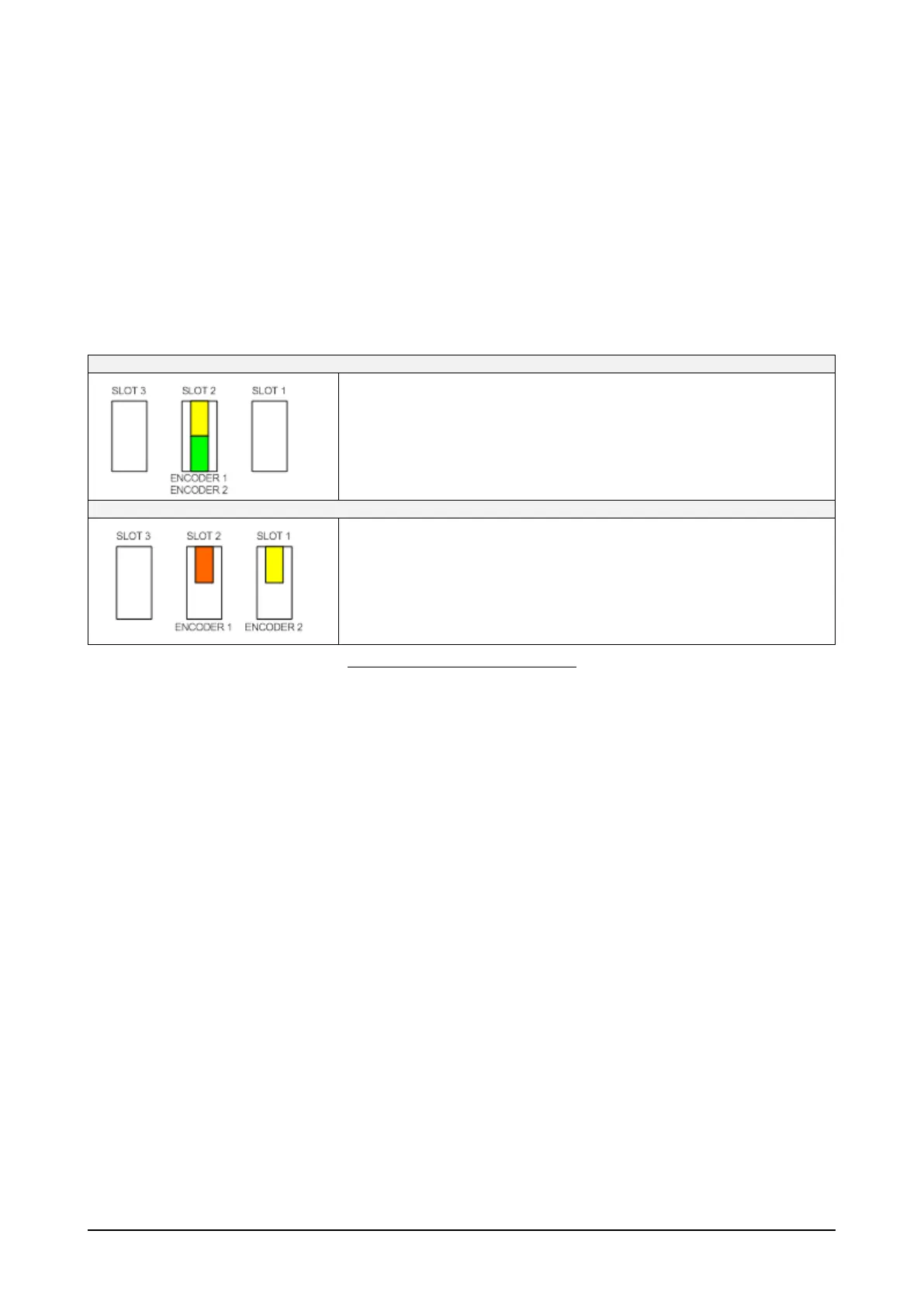

CONFIGURATION FOR ASYNCHRONOUS MOTOR WITH TWO ENCODERS

Encoder 1 (yellow) digital encoder on the metric wheel

Encoder 2 (green) digital encoder on the carriage motor

Encoder sel src = One

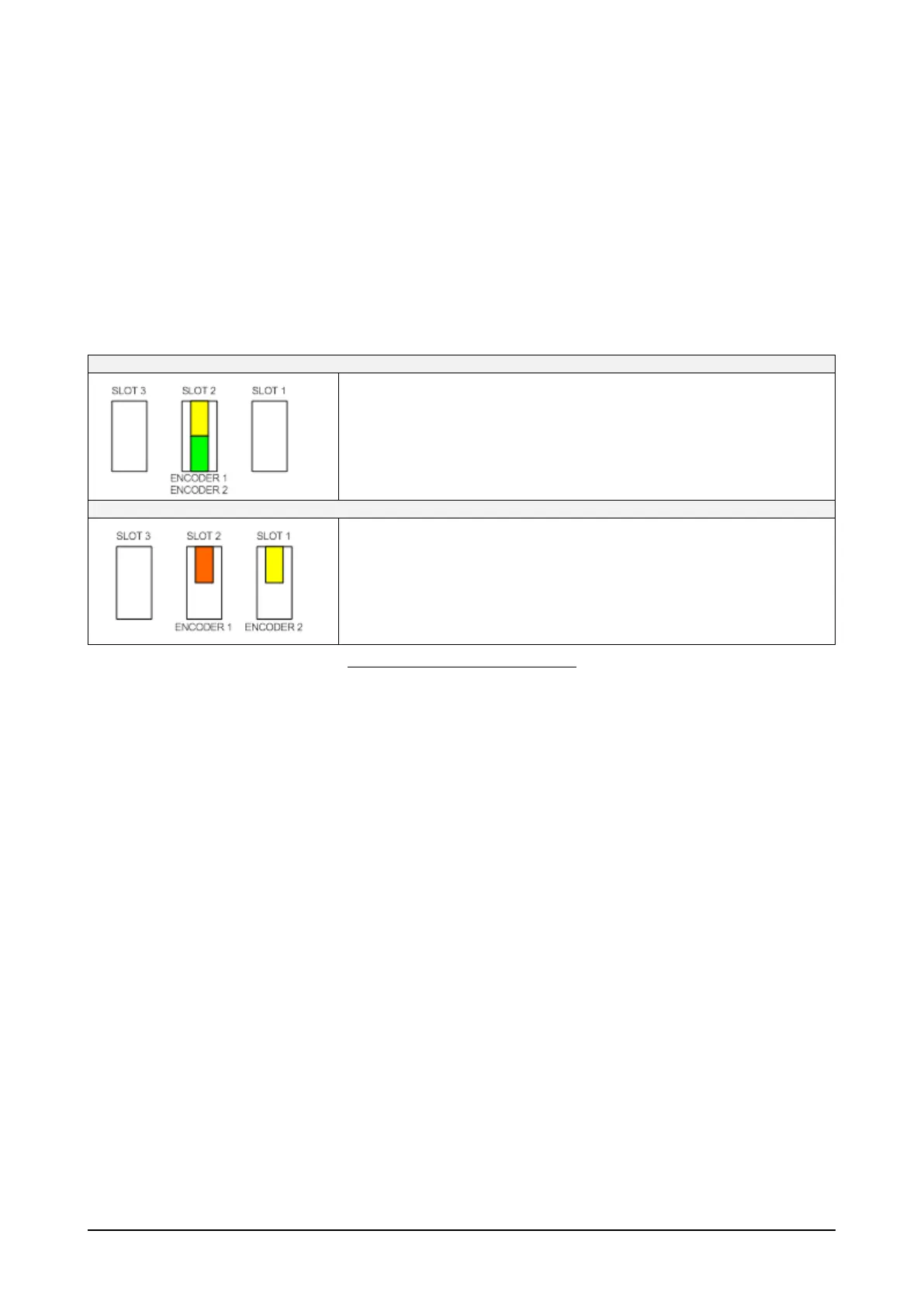

CONFIGURATION FOR SYNCHRONOUS MOTOR WITH TWO ENCODERS

Encoder 1 (red) 5-track sin cos encoder on the carriage motor

Encoder 2 (yellow) digital encoder on the metric wheel

Encoder sel src = Null

Table 3: Configuration with 2 encoders

Loading...

Loading...