Flying Shear for Roll Forming machines – Instruction manual Pag. 20 / 29

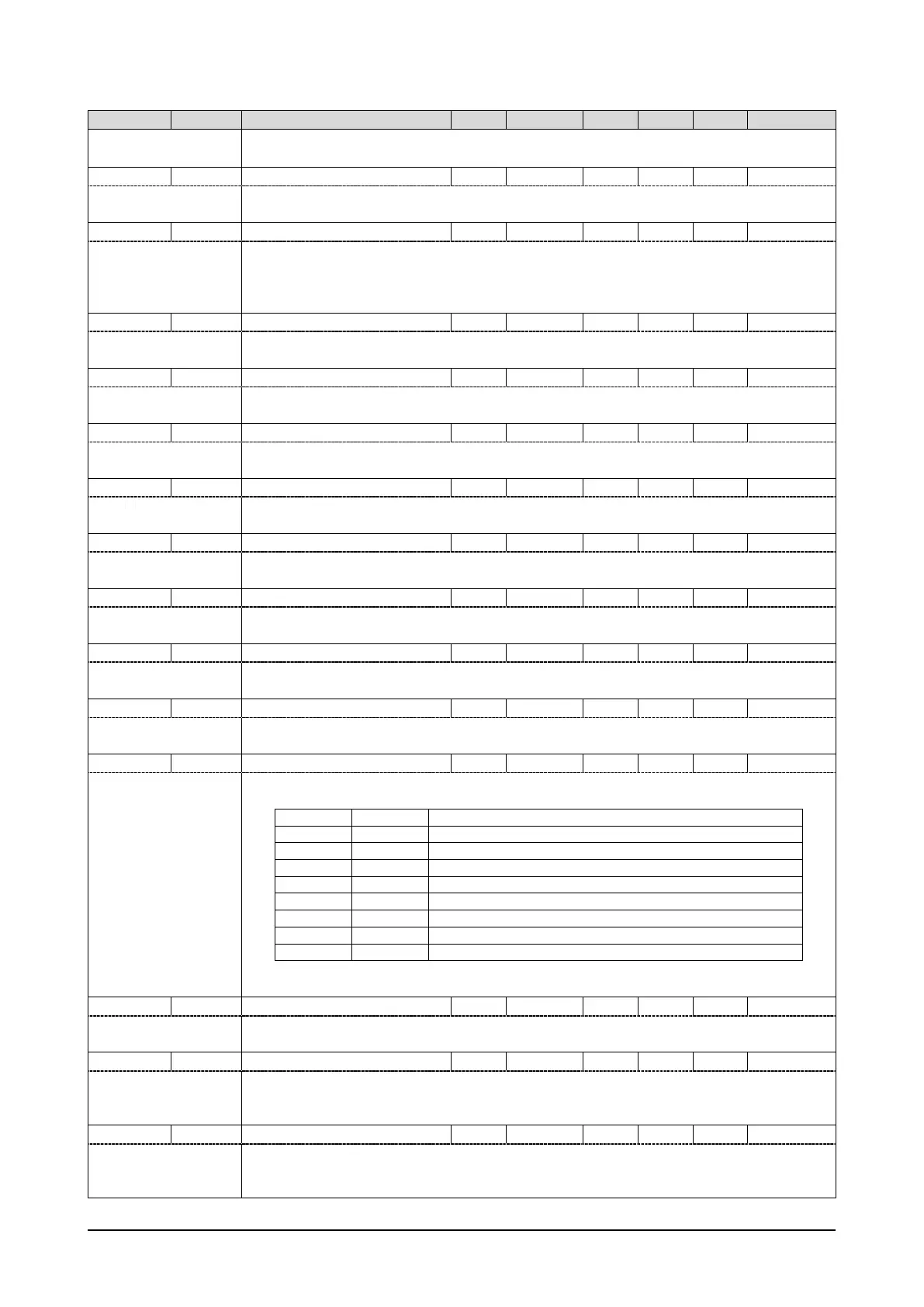

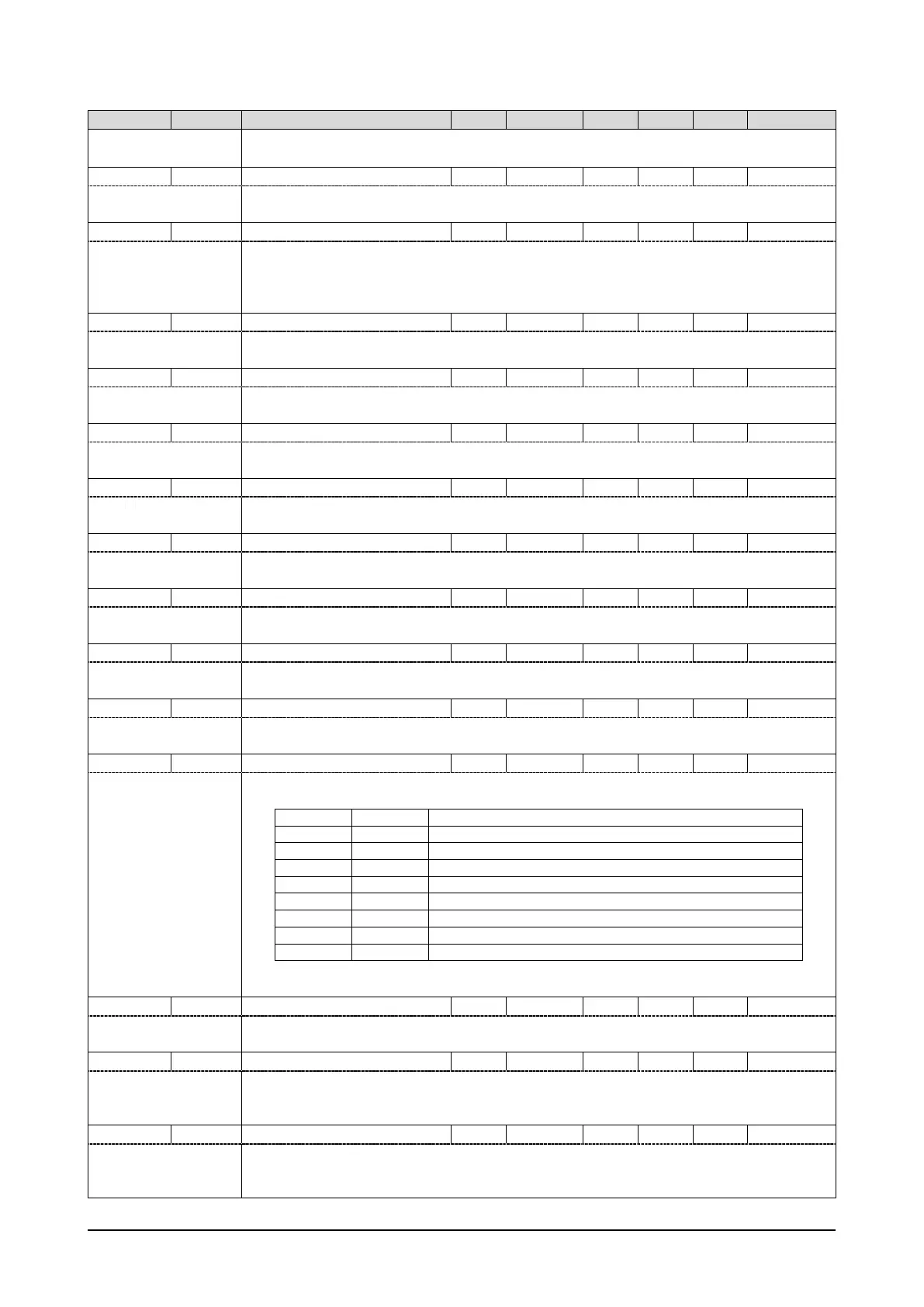

Blade simulator activation monitor.

Material count reset monitor.

Cut time monitor, measured as the time elapsed between the command being sent

and the blade release.

The monitor is updated after a cut in “automatic cut” mode, or after an immediate cut.

Acceleration time monitor.

Deceleration time monitor.

Trolley position monitor.

Monitor the length of the last cut tube.

Monitor of the material not yet cut that passed under the shear.

Maximum permitted line speed monitor.

Automated cut status monitor:

Shear deceleration at the end of the line.

Standby at the end of the line.

Shear acceleration towards the tracking start point for cut.

Constant shear speed to the tracking start point for cut.

Shear deceleration to stop at the tracking start point for cut.

Shear standby at the tracking start point for cut.

Shear acceleration at tracking start point for cut.

Synchronization and cut phase.

Required cut length monitor.

Alarm status word monitor.

(See Table 6 and Section 6 for more information)

Command status word monitor.

(See table 7)

Loading...

Loading...