Maintenance Precautions

Attach a “DO NOT OPERATE” tag

Severe injury could result if an unauthorized

person starts the engine or touches controls

during inspection or maintenance.

Stop the engine and remove the key

before performing maintenance.

Attach a “DO NOT OPERATE” tag to the

ignition switch or control lever.

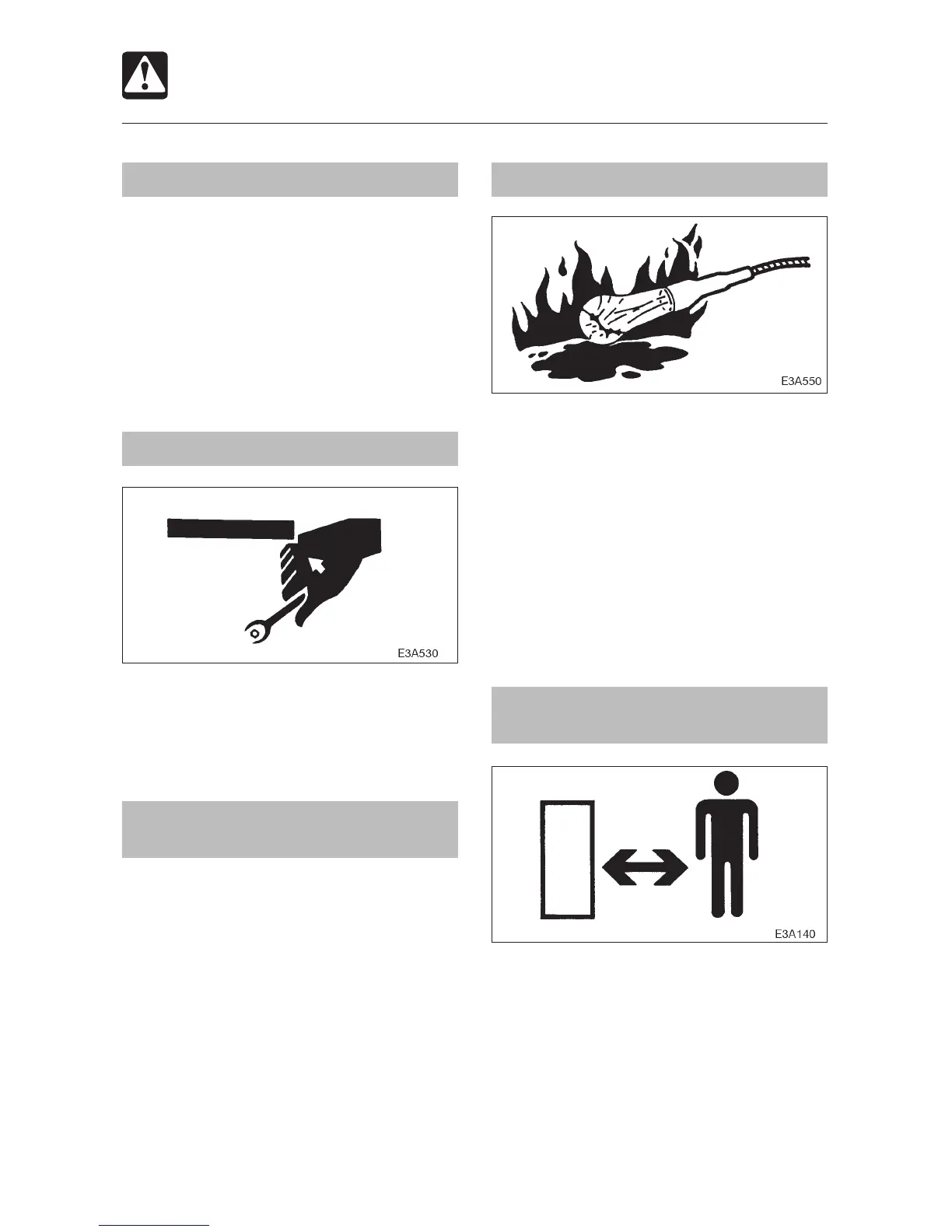

Use the correct tools

Do not use damaged or weakened tools, or

tools designed for other purposes. Use tools

suited for the operation.

Replace important safety parts

periodically

Replace fuel hoses periodically. Fuel

hoses become weaker over time, even if

they appear to be in good condition.

Replace important safety parts whenever

an malfunction is found, even if it is before

the normal time for replacement.

Refer to the section titled “Important

Parts” for further details.

Anti-explosive lighting

Use anti-explosive electrical fixtures and

lights when inspecting fuel, oil, coolant,

battery fluid, etc. If lighting that is not anti-

explosive breaks, the substance could ignite,

resulting in serious injury or death.

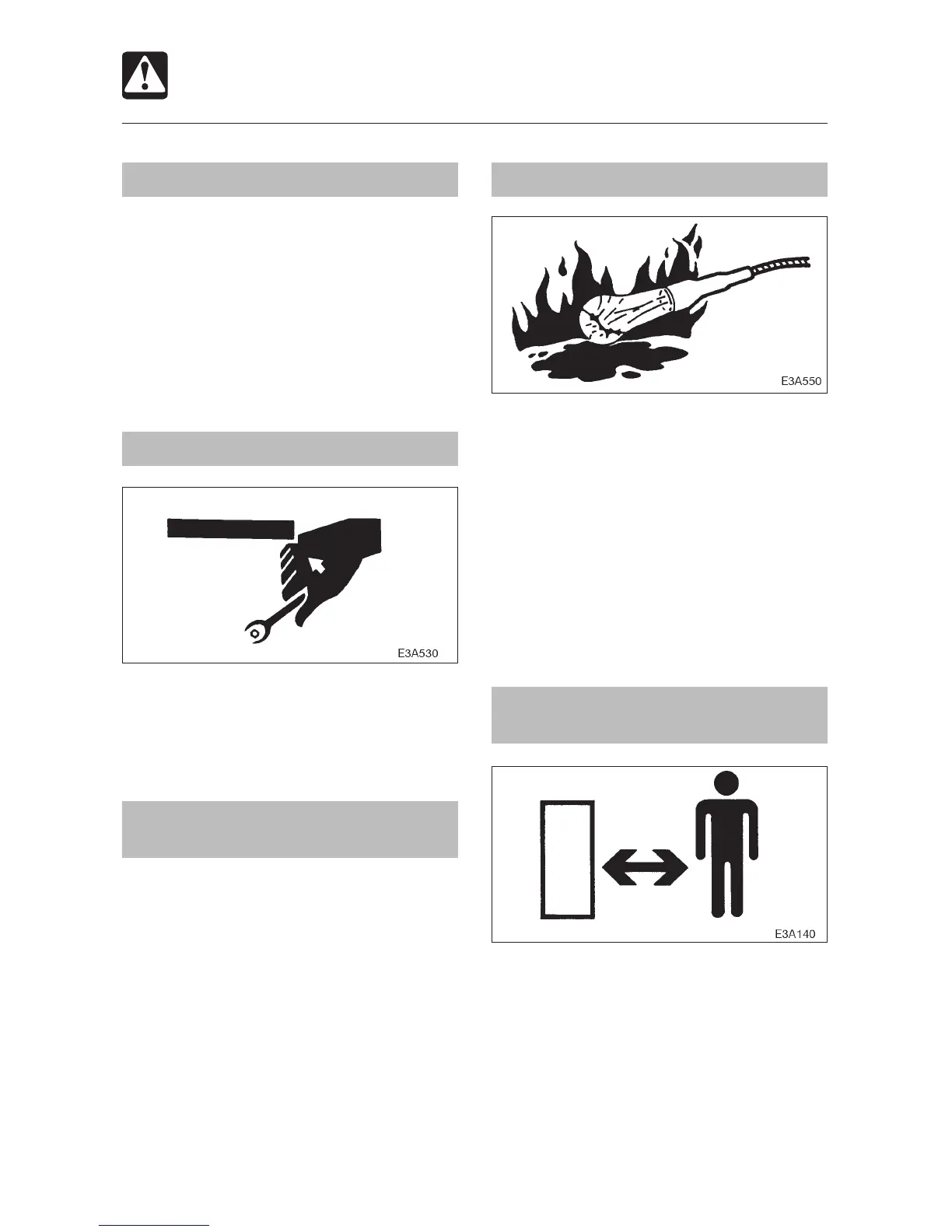

Do not allow unauthorized

personnel in the work area

Do not allow unauthorized personnel in the

work area. Chips or other debris can fly off

machine parts when grinding, welding or

using a hammer.

Loading...

Loading...