www.gemu-group.com 21 / 32 GEMÜ 1434 µPos

NOTICE

Wrong mounting kit

▶ If no initial spring tension can be felt, it may be the case

that the wrong mounting kit with too short an operating

bush has been used.

▶ If the spring locks and the positioner cannot be correctly

mounted on the valve, it may be the case that the wrong

mounting kit with too long an operating bush has been

used or that a required adapter has not been used.

▶ In both cases, check the mounting kit parts and that they

are being used correctly and in their entirety.

4. Tighten the product 1 with the flat (size depending on ver-

sion) of the adapter 2.

5. Turn the housing clockwise to align the pneumatic or elec-

trical connections.

CAUTION

Incorrect installation of the product.

▶ Damage to the housing.

● Only tighten the product using the spanner flats provided

for this purpose.

The product with mounting kit. The product with mounting kit

and adapter.

• Mounting with or without the adapter depends on the re-

quirements of the construction. If an adapter is required, it

is included.

6. Connect the pneumatic supply to the positioner 1 and con-

nect to the process valve 3.

10.6 Direct mounting with mounting bracket

NOTICE

▶ The construction of the product with a mounting bracket

is used for valves which have larger position changes

than the integrated travel sensor on the positioner can de-

tect.

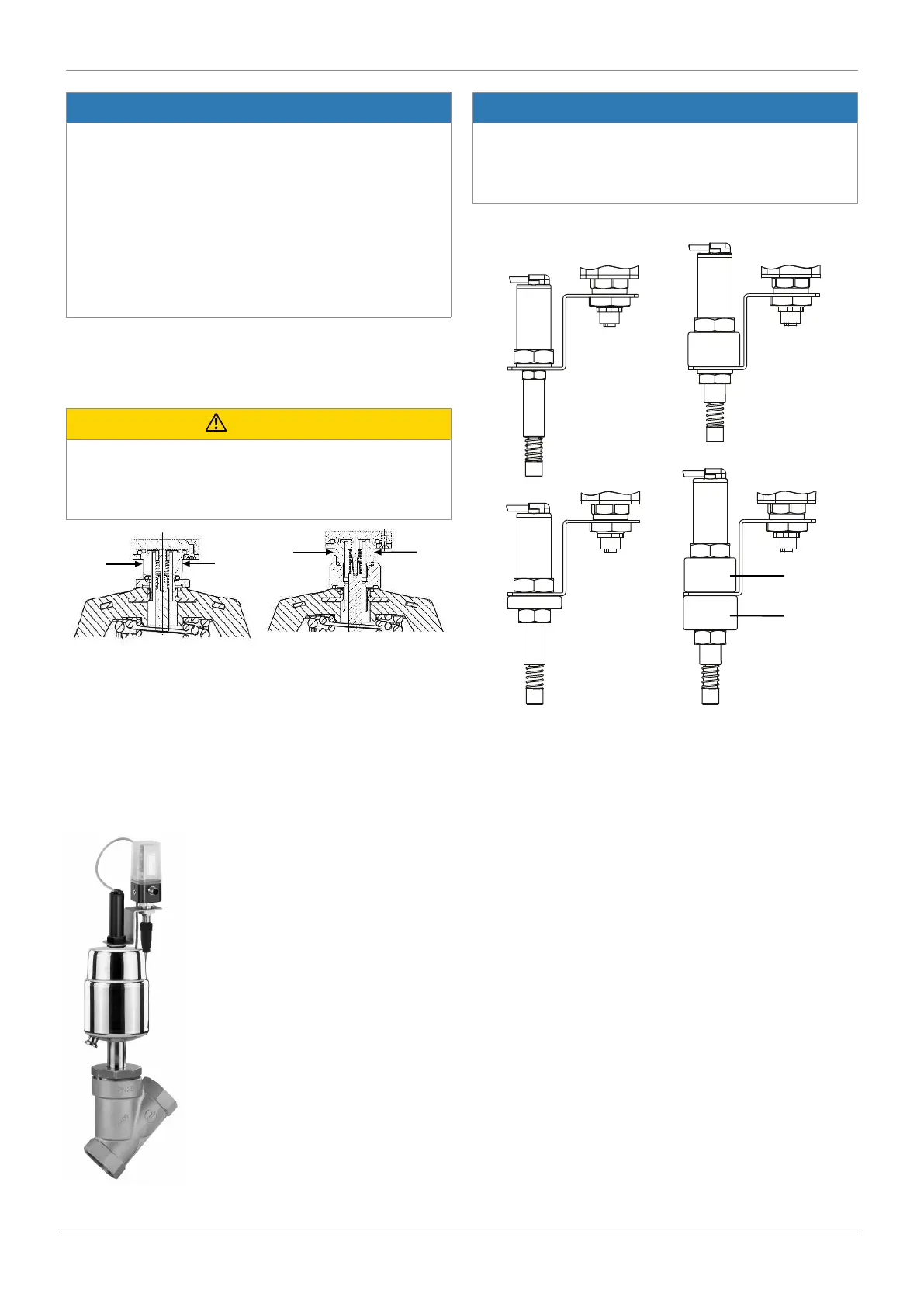

The following four versions are available:

Version 1:

Mounting bracket is fastened via the travel sensor without an

adapter.

Version 2:

Mounting bracket is secured via the adapter. Travel sensor is

screwed into the adapter.

Version 3:

Mounting bracket is fastened via the travel sensor and the ad-

apter screwed into the actuator opening.

Version 4:

Mounting bracket is fastened between the screwed-in adapter

in the actuator opening and a second adapter. The travel

sensor is screwed into the upper adapter. O-rings are located

between the adapters.

10 Mounting

Loading...

Loading...