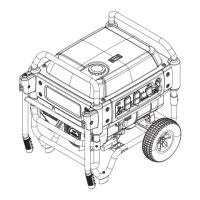

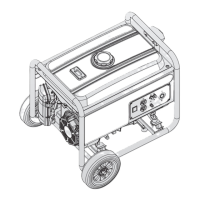

This document is an Owner's Manual for Stationary Industrial Generators, specifically covering models 0065791 and 0065771, which are standalone gas units. The manual emphasizes that installation and initial startup are not "do-it-yourself" projects and must be performed and documented by an Authorized Service Dealer or other competent, qualified contractor. It also stresses the importance of reading the manual thoroughly and understanding all instructions for proper and safe use.

Function Description:

The Generac Stationary Industrial Generators are revolving field, alternating current type generator sets designed to supply electrical power to compatible electrical loads when the utility power supply is unavailable or has dropped to an unacceptable level. The generator's revolving field is directly connected to and driven by an engine, either by flexible discs or a gearbox. Four-pole rotors operate at 1,800 rpm for 60 Hertz frequency or 1,500 rpm for 50 Hertz frequency. The units are equipped with a control panel (H-100 Panel Interface) that allows operators to monitor and manually start the generator, and it includes protective devices to ensure safe operation.

Important Technical Specifications:

- Models Covered: 0065791, 0065771

- Fuel Type: Standalone Gas (Natural Gas or LP Gas, with options for vapor or liquid withdrawal, and dual fuel NG/LP systems).

- Engine Oil Recommendations:

- Gaseous Engines (6.8L displacement or smaller): SAE 5W-20

- Gaseous Engines (Displacement larger than 6.8L): SAE 40

- Diesel Engines: SAE 15W-40

- Recommended API Service Category for gaseous engines: SJ, SL, SM, or SN.

- Recommended API Service Category for diesel engines: CH-4, CI-4, or CJ-4.

- Coolant: Deionized or distilled water and Ethylene glycol antifreeze (50-50 mixture recommended). Propylene glycol can also be used but not mixed with Ethylene glycol.

- Gearbox Lubrication (If Equipped): SAE 90 gear oil with Lucas Heavy Duty Oil Stabilizer (specific volumes provided for 390 and 520 Gearbox models).

- Voltage Codes: A variety of single-phase and three-phase voltage options are available, ranging from 110/220 volts (50 Hz) to 346/600 volts (60 Hz), with different lead configurations.

- Load Imbalance Limits (Three-Phase Units): Maximum load imbalance between phases cannot exceed 25% of rated load (current).

- Engine RPM Rating: 2,300 Engine rpm rating (15 = 1500 rpm, 18 = 1,800 rpm, etc.). Engines operating above 1,500 or 1,800 rpm use a gearbox to reduce engine rpm to the desired alternator rotor rpm.

- Alternator Features: Class "H" rated rotor and stator insulation, self-ventilated and drip-proof construction, acceptable voltage waveform deviation, total harmonic content, and telephone influence factor according to NEMA MG1-22. All prototype tested models have passed three-phase symmetrical short circuit tests.

- Battery Chargers: Available in 2.5-amp (12 VDC only) and 10-amp (12 VDC or 24 VDC) float types, fully automatic and fuse protected.

Usage Features:

- Control Panel (H-100 Panel Interface): Allows monitoring and manual starting. Includes an Emergency Stop Button, Common Alarm Horn, Key Switch (AUTO, OFF, MAN positions), Left Display Window (Volts, Amps, Frequency, Hertz, Kilowatts), Right Display Window (Alarm information, HOME menu, MENU for navigation), and Arrow Keys Pad.

- Automatic Operation: When connected to an Automatic Transfer Switch (ATS) and the generator control is in the AUTO position, the unit will automatically start upon sensing a utility power loss or reduction.

- Manual Operation: Can be manually started and transferred to load using a Manual Transfer Switch. Specific steps are provided for manual engine startup, transfer, re-transfer, and shutdown.

- Protective Devices: Numerous sensors provide information to the control panel to protect the engine and generator, including coolant temperature, low coolant level, oil pressure, overspeed, overcrank, RPM sensor loss, and low fuel pressure warnings. The control panel is designed to shut down the engine if potentially damaging conditions occur.

- Starting Aids (If Equipped): Engine coolant heater, engine oil sump heater, and battery warmer are available to ensure quicker, easier starts in cold conditions. These are powered by the utility source during non-operating periods.

Maintenance Features:

- Maintenance Schedule: Detailed schedules are provided for various intervals:

- Extended Run-Time Maintenance Checks: Daily checks (every 24 continuous operating hours) for leaks, loose components, fluid levels, belts, hoses, and fuel system.

- Maintenance Level 1A (One-Time): Post-installation inspection after 50 hours or 3 months, requiring 2.5 hours. Includes checking valve clearance (if applicable), changing engine oil and filter, checking belts, hoses, wiring connections, and a 15-minute load test.

- Maintenance Level 1 (Monthly): Or every 24 hours of operation, requiring 0.5 hours. Includes checking engine oil, coolant, battery electrolyte, battery connections, charger operation, air inlets/outlets, fuel system, and a 5-minute no-load operational test.

- Maintenance Level 2 (Semi-Annual): Or every 100 hours of operation, requiring 2.0 hours. Includes checking belts, hoses, load testing battery, and a 15-minute load test.

- Maintenance Level 3 (Annual): Or every 250 hours of operation, requiring 6.0 hours. Includes changing engine oil and filter, inspecting air filter, inspecting/gapping spark plugs and ignition wires (gaseous units), testing/filtering diesel fuel and changing filters (diesel units), checking belts, hoses, radiator, coolant thermal protection, wiring connections, and a 1-hour load test.

- Maintenance Level 4 (Bi-Annual): Or every 500 hours of operation, requiring 6.0 hours. Includes changing gearbox oil (if equipped), replacing air filter(s), replacing spark plugs (gaseous units), replacing belts, draining/flushing cooling system, replacing flexible hoses, and a 2-hour load test.

- Disabling for Maintenance: Procedures are outlined for safely disabling the generator from starting, including setting the control panel to OFF, removing the control panel fuse, turning off battery charger power, and disconnecting the negative battery cable.

- Battery Inspection and Replacement: Instructions for monthly visual inspection, semi-annual hydrometer testing, and replacement with equivalent size, voltage, and CCA battery. Emphasizes safety precautions when working with batteries due to explosive hydrogen gas and caustic electrolyte.

- Gearbox Oil Check/Change: Monthly or every 100 operating hours for level checks, and biannually or every 600 hours for draining and refilling.

Loading...

Loading...