13-1

SECTION 13: ENGINE ASSEMBLY

INSTALL CRANKSHAFT

Lubricate magneto bearing and inside edge of oil seal with engine oil

and install crankshaft.

Figure 13-1. Installing Crankshaft

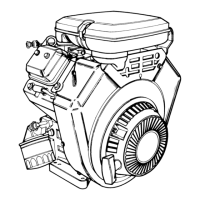

INSTALL PISTON AND CONNECTING ROD

Note: Install #1 piston and connecting rod first.

1. Lubricate piston rings, piston skirt, and Ring Compressor, with

oil.

a. Rotate the rings so that the ring end gaps are 90 degrees from

each other.

b. Place piston inside of ring compressor and set upside down on

bench with projections on compressor facing up Figure 13-2.

c. Tighten ring compressor until rings are fully compressed.

d. Remove connecting rod cap.

2. Lubricate cylinder bores and crankpin and rotate crankshaft until

it is at bottom of stroke.

3. Install #1 piston with notch or casting mark towards flywheel

side. See Figure 13-3.

a. Push piston down by hand, or with a wood handle, until

connecting rod is seated on crankpin.

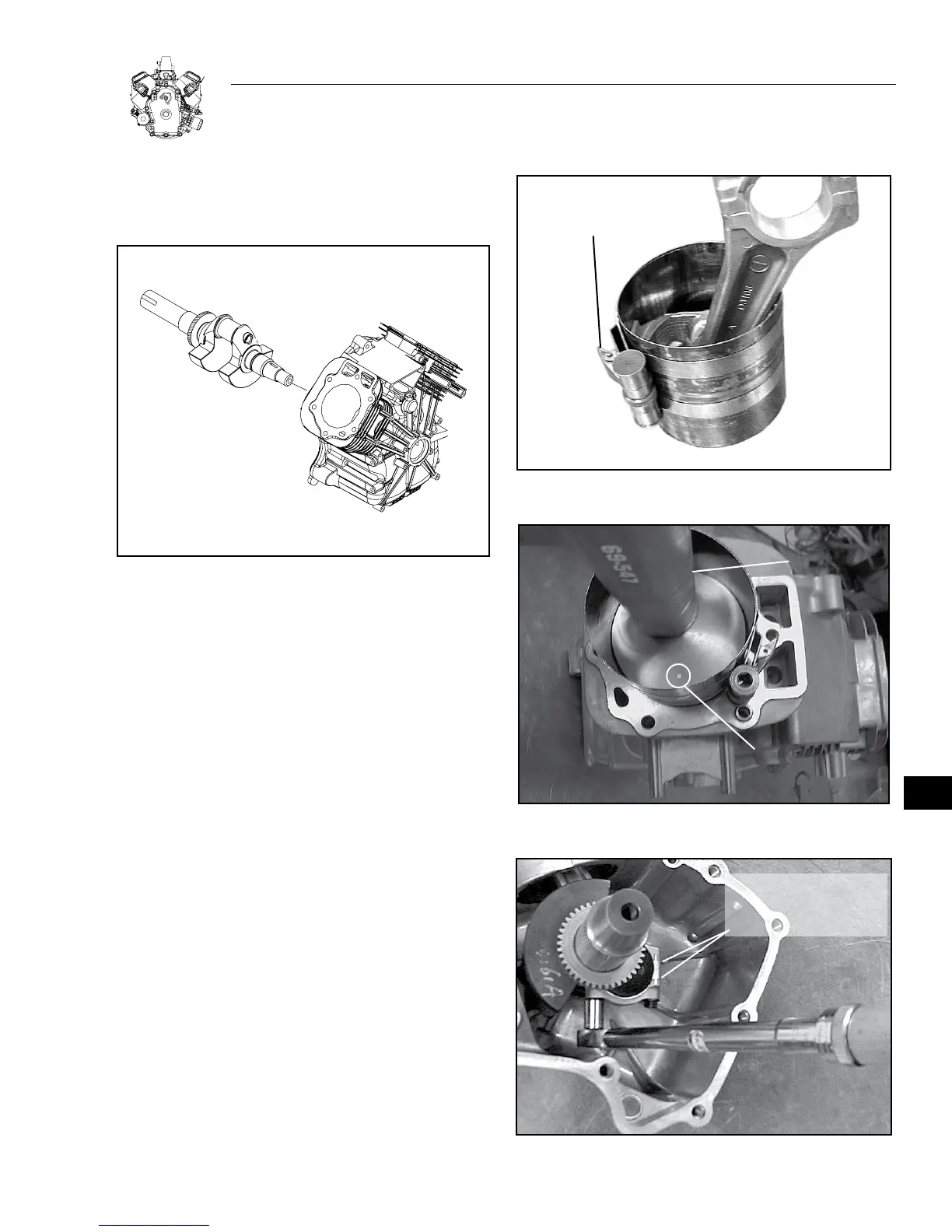

4. Assemble connecting rod cap to rod with match marks aligned,

Figure 13-4.

a. Torque screws to 24.4 Nm (216 in. lbs.).

5. Rotate crankshaft two revolutions to check for binding. Rod should

also be free to move sideways on crankpin.

Repeat Steps 1-5 for #2 cylinder.

RING

COMPRESSOR

Figure 13-2. Compressing Rings

NOTCH OR

CASTING MARK

TOWARD

FLYWHEEL SIDE

HAMMER

HANDLE

Figure 13-3. Installing Piston And Connecting Rod

ALIGN MARKS ON

ROD AND CAP

WHEN ASSEMBLING

Figure 13-4. Torque Connecting Rods (#2 rod shown)

13

Loading...

Loading...