210 ONE MAN HOLE DIGGER, FORM GOM-1061-1189, VERSION 2.0, AUTHORIZATION: DVR, PAGE: 21

The 210 Hole Digger utilizes a fully enclosed, double

reduction transmission for multiplying and transmitting

engine torque to the auger. The principle involves

engine horsepower and torque being transmitted

through a centrifugal clutch and two sets of gear

reductions into a final driveshaft. Grease is provided for

lubrication and heat dissipation for the bearings, gears

and clutch assembly.

A pressure relief valve, PN 5677, is located on the top

surface of the transmission cover to relieve any excess

pressure created in the transmission due to heat rise.

Should this valve become plugged, the following

problems can occur:

1) Lubrication grease can be forced out between the

bearings and the final driveshaft.

2) The gasket that separates the two halves of the

transmission can push out, causing a loss of lubrication

grease.

The potential for these problems can be minimized by

cleaning the pressure relief valve at regular intervals

with an approved safety solvent. The transmission is

shipped from the factory filled with approximately 6

ounces (0.2 liter) of high temperature lubricant. This

lubricant contains an extreme pressure additive which

is designed to cling to the gear teeth at high rotational

speeds.

1) Change the transmission lubricant every 25 hours of

operation, or more often as necessary, if the Hole

Digger is operated in extremely dusty or dirty

conditions.

2) Drain the gasoline from the gasoline tank into a UL®

approved container. Refer to the material supplied by

the engine manufacturer for more detailed information.

3) Position the Hole Digger on a suitable work bench

with the operator handle level with the ground. Wipe

any dust or dirt from the area where the transmission

separates.

GASOLINE IS AN ETREMELY FLAMMABLE FUEL.

USE EXTREME CAUTION WHEN HANDLING

GASOLINE. DO NOT SMOKE OR BRING FIRE OR

FLAME NEAR THE FUEL.

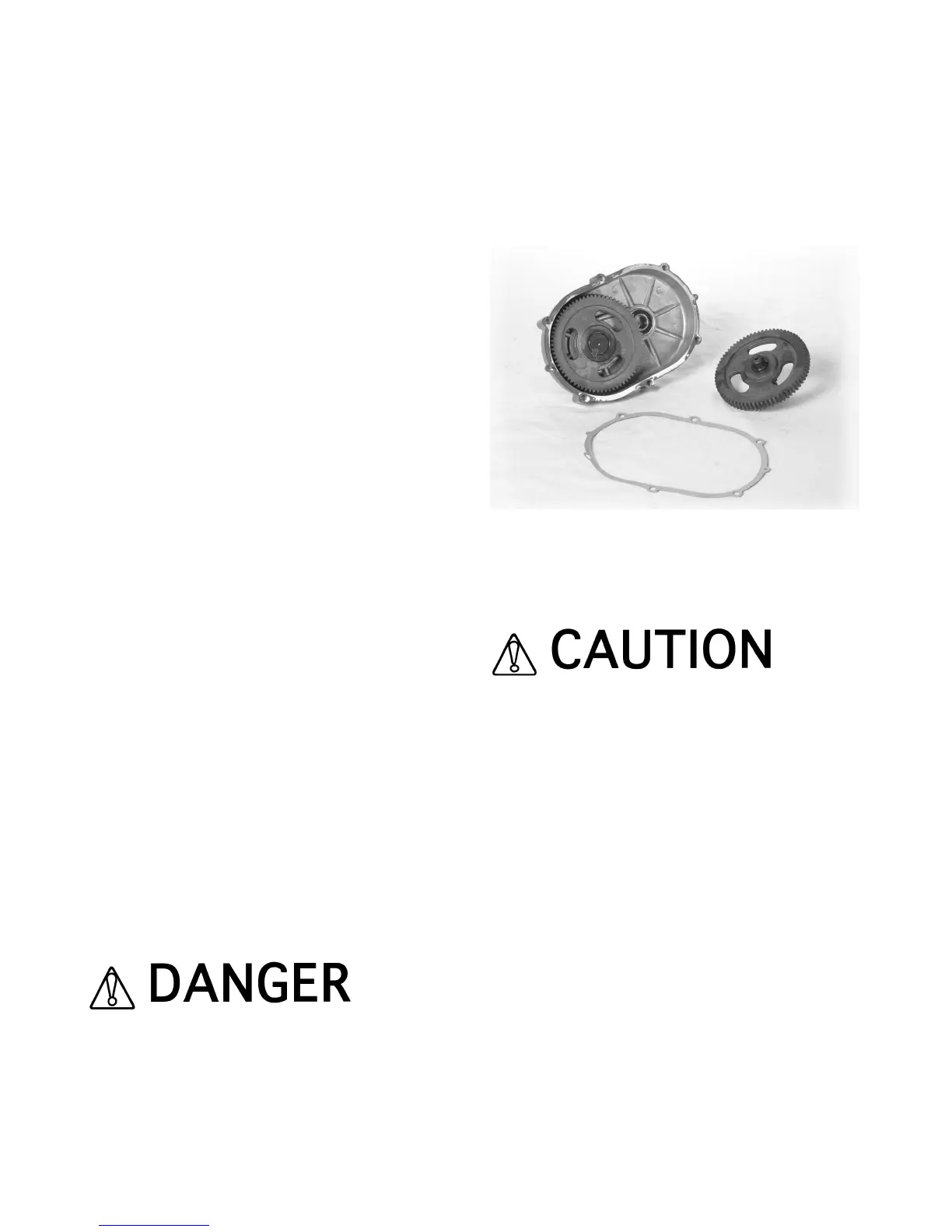

4) Split and separate the transmission cover and case.

Exercise caution not to damage the dowel pins.

Remove the PN 210-0100 gasket. Remove the

primary gear and pinion assembly, PN 210-0340 and

PN 210-0310. FIGURE 12.

FIGURE 12

5) Clean the interior of the transmission cover and case

with an approved safety solvent.

Observe all applicable safety precautions for the

solvent. Dispose of the used transmission

lubricant according to all applicable laws and

regulations.

6) Fill the transmission cover and case with 6 ounces

(0.2 liter) of high temperature transmission grease

containing an extreme pressure additive. Part Number

210-0720 lubrication grease or Fisk Brothers GR-132

is an approved lubricant. FIGURE 13. Distribute the

grease equally around the gear teeth. Do not utilize

standard lithium based greases intended for common

lubrication purposes. These types of grease are not

formulated to operate at the higher operating

temperatures encountered during the hole digging

process. Such greases also do not contain an extreme

pressure additive for use with gears. FIGURE 14.

Loading...

Loading...