46 - Tekniske ændringer forbeholdes - Technische Änderungen vorbehalten - Subject to Technical Modications - 830209G/160228

3. Maintenance

The following instructions must be followed in order to

ensure optimum operation of the unit:

The power supply to the system must always

be switched off before opening the cover.

When the unit has been installed for the rst time make

sure the water drains are checked after a few days to

make sure they are performing well.

Environmental considerations

When the unit is being serviced or its operation is

cancelled, please make sure to follow the guidelines for

recovery and disposal of all materials according to local

procedures and laws.

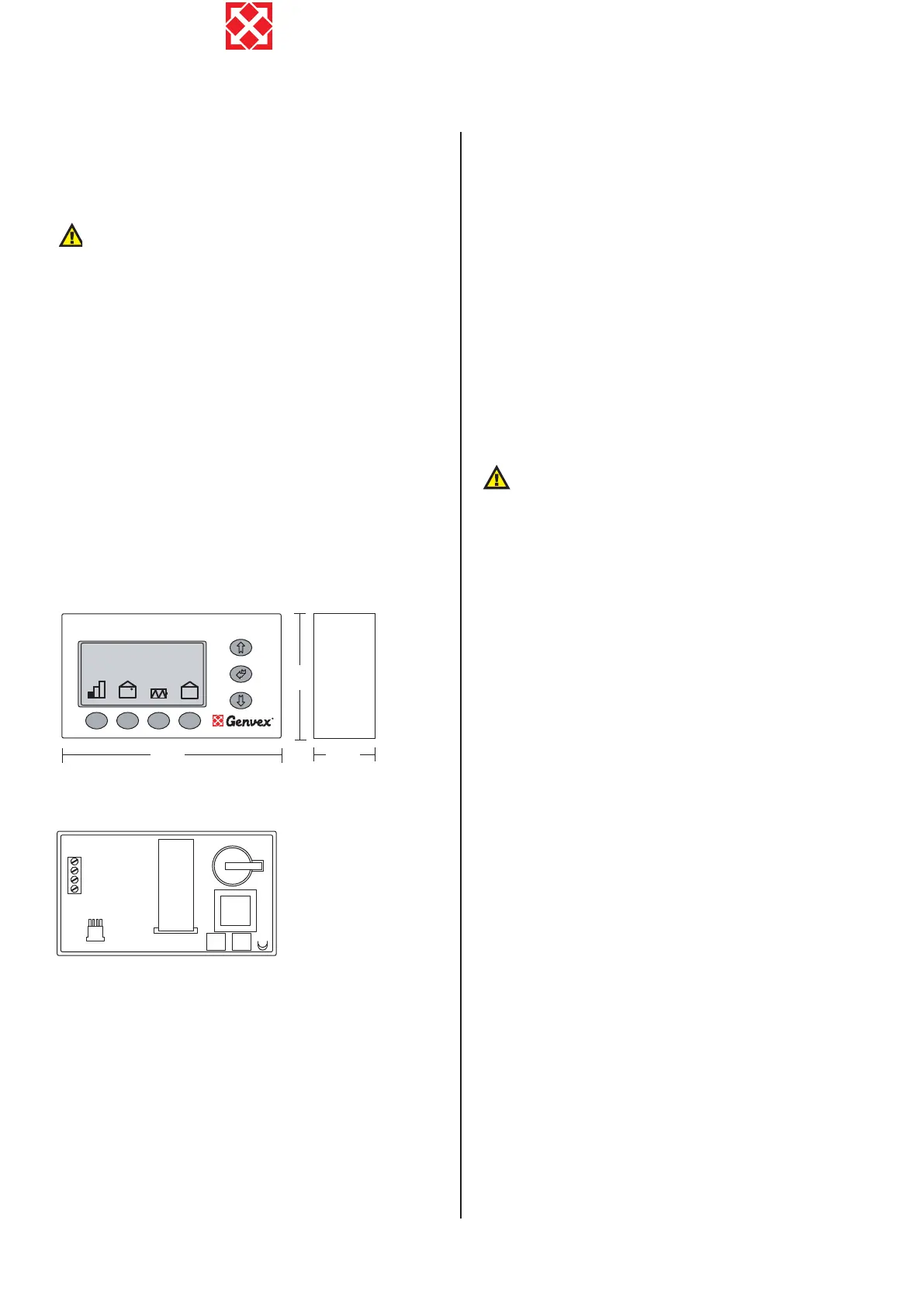

3.1 Connecting to computer

In order for the optima 300 to communicate with the

computer (data logger) the communication box “Genvex

data logger” has to be installed between the controller

and the computer. The data logger is accessory

equipment and can be required at Genvex A/S.

70

120

25

C I

ON/OFF

Roomtemperature

21.5

o

C

Wednesday 12:18

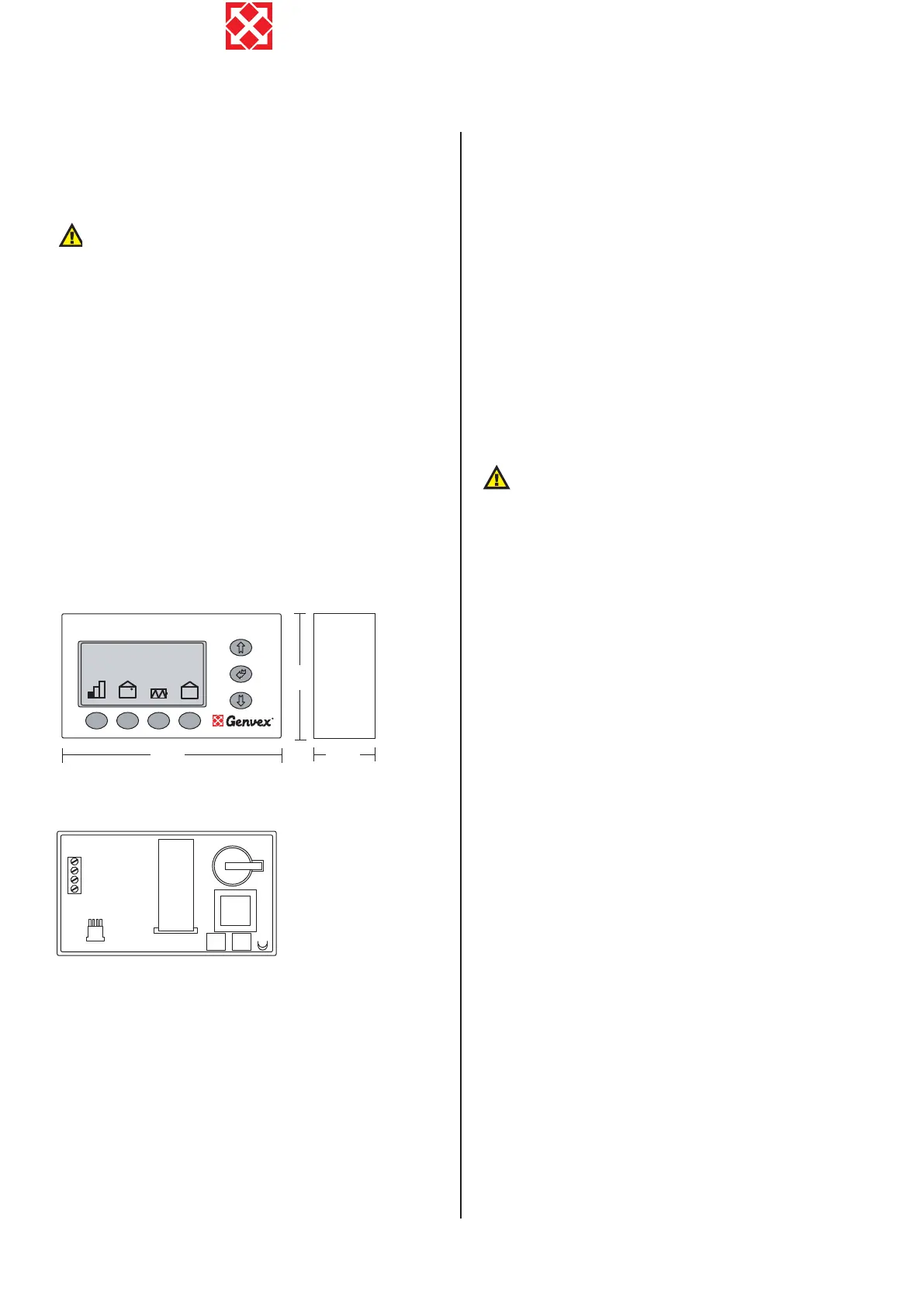

Cable access (bottom rear)

rear side

A: Terminal block. Power connection.

B: Room sensor T2.

C: Communication plug to computer (data logger).

D: Data collection IC circuit (Red).

E: Processor control panel.

F: Battery.

G: IC circuit (black).

Between the unit and the control panel a light current

cable 4 x 0.25 mm

2

should be mounted. The maximum

cable length is 30 m.

3.2 Servicing

Filters:

When the red lamp on the control panel ashes, the

lters must be changed/cleaned. Stop the unit with the

switch on the unit or the electrical panel. Open the front

cover and take out the bag lter and at lter. The bag

lter may be cleaned two or three times with a vacuum

cleaner before replacing it. The at lter can be taken out

of its frame and washed in warm soapy water. Keep the

lter diagonally so the water runs out. The lter must not

be wrung out or washed in dishwasher. After two or three

washes, replace the at lter. Place the at lter in its

frame, set both lters in the unit and close the front cover.

Then switch on the unit and press the enter button on the

control panel for 10-15 seconds until the Genvex logo

starts ashing again and the equipment is back in normal

operation.

Careful handling of the plates is required. They

have sharp edges and must not be damaged.

Condensate drain:

When changing the lters in the autumn season check

the condensate drain and tray for blockage by dirt. Fill

water in the condensate tray and check that the water

runs out unhindered. Should this not be the case the

drain must be cleaned. At the same time make sure that

the plates of the evaporators are clean.

Heat exchanger:

Inspect the countercurrent heat exchanger every three

years. If it is dirty, remove it and wash in warm soapy

water and then rinse, possibly in the bathroom using the

shower head.

Fans:

Every three years check the two fan wheels for dirt. If

they are dirty they must be cleaned with a brush, bottle

washer etc. Please notice that the balance weight of the

fan wheels are not removed causing an unbalance and

thereby a higher noise level and abrasion of the fans.

Supply and extract valves:

Clean the valves by wiping with a dry cloth. Make sure

the valve does not rotate, causing a change in the air

volume.

3.3 Demounting

The following actions must be taken:

Disconnect the power supply to the unit and disconnect

other connections. Shutoff the fresh water supply valve

and connect a drain hose to the drain valve in order to

drain the water. While draining, a hot tap water valve

should be opened to avoid under pressure in the tank.

The air duct connections are uninstalled and remaining

air channels must be closed to avoid condense water

entrance to the building.

ENGLISH

Loading...

Loading...