This sensor is preinstalled in all machines, used only when Edge Finder option is activated

It’s located in the back-down position of the carriage. It consists in an infrared sensor that detects if there

is paper or not.

On the start procedure and when paper changes, the machine scans the paper to nd the left and right

edge position.

With the Edge Finder option, the plotter knows the paper position, and avoids out of paper prints.

PAPER ENCODER READER

Description:

The plotter reads the paper movement from the encoder

reader, to ensure the proper marker lenght.

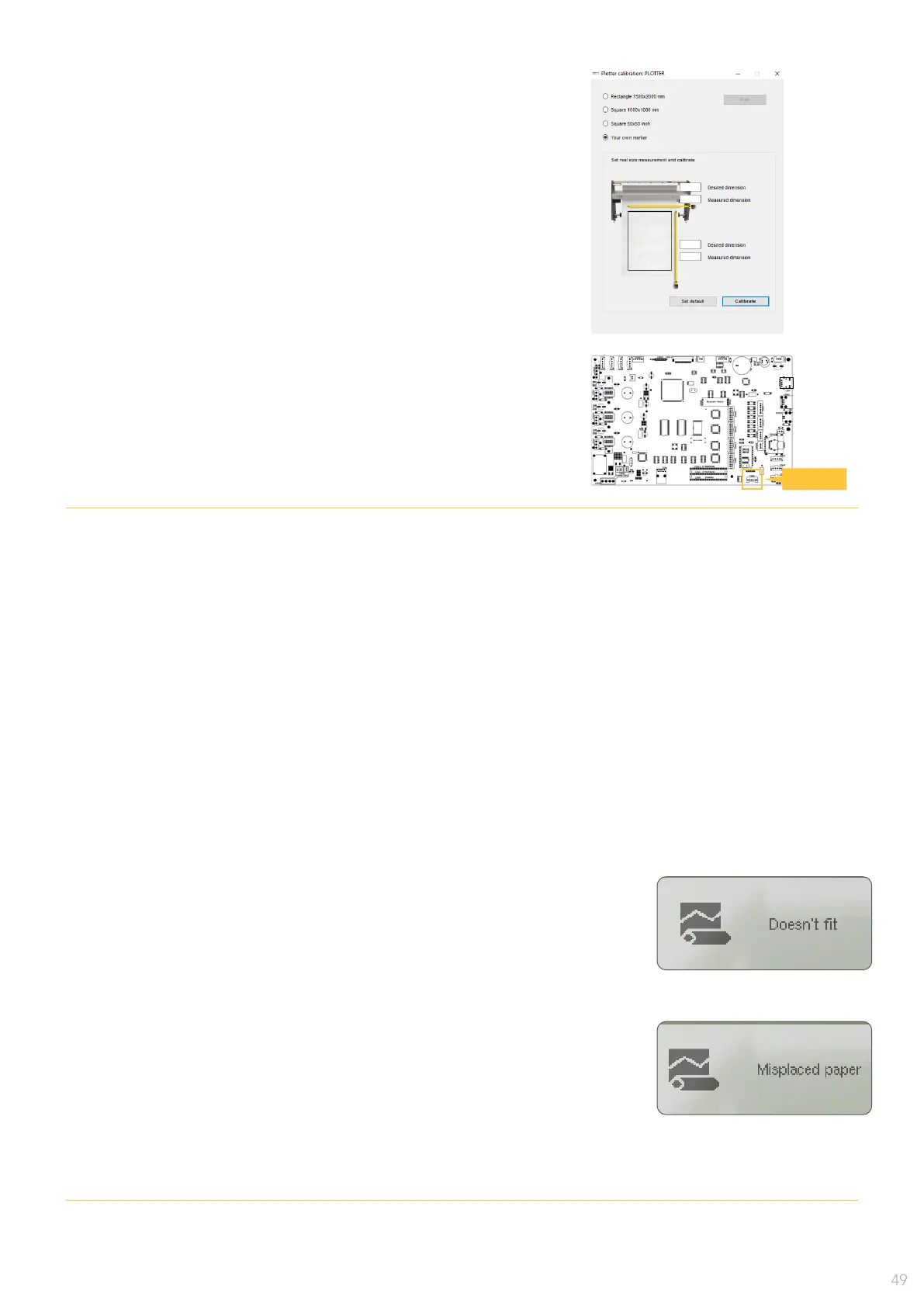

Mechanical tolerances are compensated using the software

calibration le located in the

User manager > Conguration > Plotter calibration.

This correction values are saved in the plotter and the software

uses them to rasterize the les.

If this value is changed, the les in the queue must be rasterized

again avoid wrong size values.

The encoder is connected to the main board in CON5.

PAPER WIDTH SENSOR

Description:

CON5

1. Verify that the paper width is properly set and adjusted on the plotter.

Doesn't fit

Paper is not properly set on position.

1. Verify that the paper is not covering the «origin» label located on the

printing bridge.

Description:

Misplaced paper

Loading...

Loading...