8

Installation instructions

5018606-00 Rev.C Edition 0704

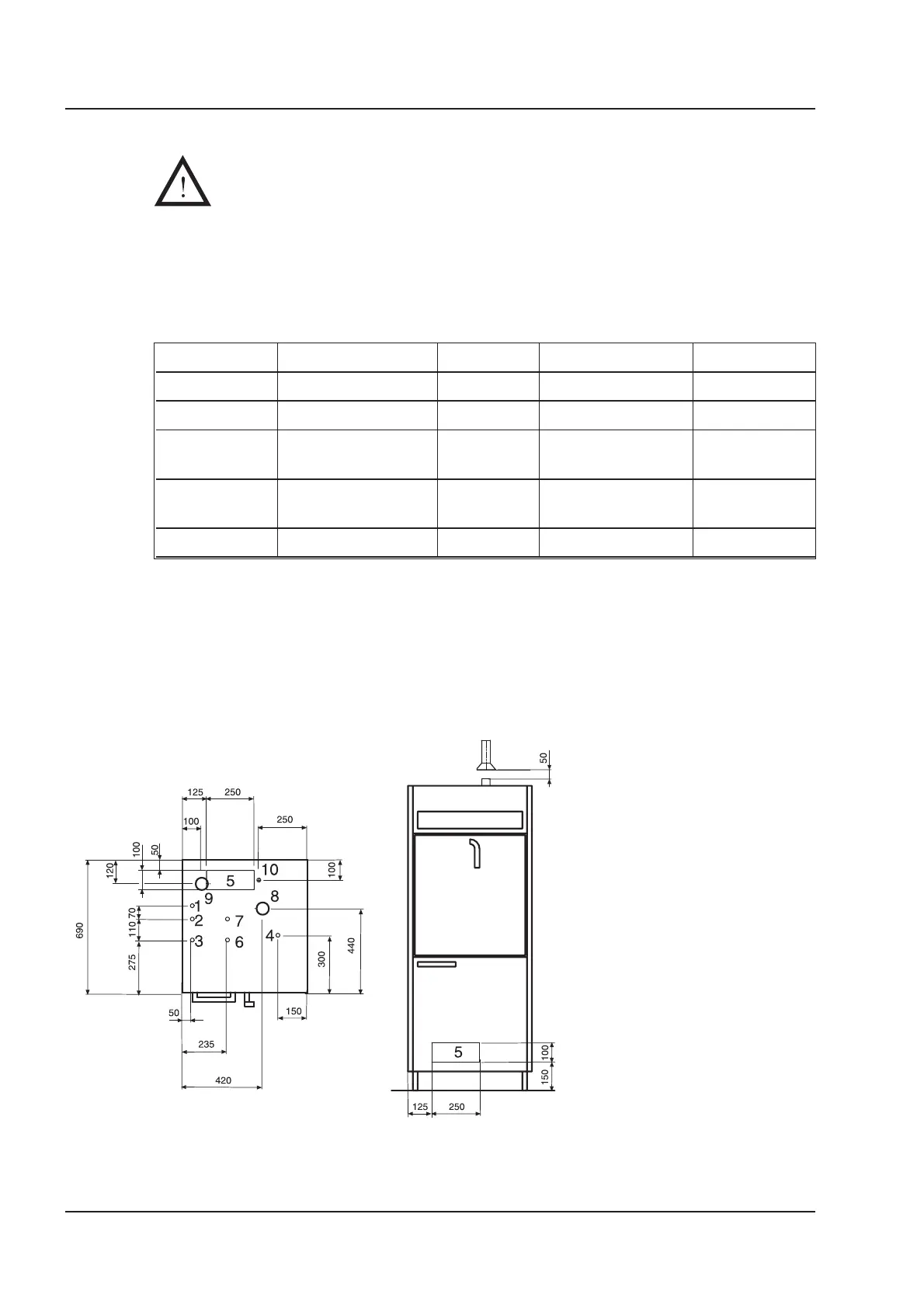

1. Distilled/de-ionized water 160 mm above

the floor*.

2. Hot water, 245 above the floor, flexible

hose, L= 1500 mm supplied*.

3. Cold water, 305 mm above the floor,

flexible hose, L= 1500 mm supplied*.

4. Electrical connection , 500 mm above floor.

5. Waste, adjustable within this range

(C/L of outlet pipe)

6. Steam connection, 200 mm above floor.

7. Condensate connection, 200 mm above

floor.

8. Dryer, exhaust air, at roof, 46-4, 46-5

9. Dryer, exhaust air, at roof, 46-2

10. Distilled/de-ionized water without

pressure, 200 mm above the floor.

* A flexible hose can be connected from

above directly to the valve 1400 mm above

the floor. A hole for the hose in the ceiling or

cover plate must be made on site.

Figure 8. Connecting water, steam, waste and dryer

Connecting water, steam, waste and dryer

Installation may only be done by authorized personnel.

• Provide separate shutoff valves on the water and (if used) steam lines. Flush out

the water and steam pipes that are to be connected to the machine, to prevent

clogging of filters and valves.

• Connect the disinfector to cold and hot water and to steam and condensate

connections, if used. The connections must meet the following requirements:

• PTFE tape is recommended for sealing the connections.

NOTE:

Distilled or de-ionised water must have a conductivity of less than 40 μS/cm.

Installation

* Where the pressure is lower than 50 kPa a separate feeder pump must be used. Where a separate

feeder pump is used, the pressure must not exceed 60 kPa (risk of serious damage to the pump).

V1632

Connection Pressure Consumption Flow rate

Cold water 1/2" (15 mm) female 100-800 kPa approx 15 liters/phase min 20 l/min

Hot water 1/2" (15 mm) female 100-800 kPa approx 15 liters/phase min 20 l/min

Dist. water/ 3/4" (20 mm) male 50-900 kPa* approx 15 liters/phase min 20 l/min

De-ion. water

Steam 1/2" (15 mm) female 300-500kPa 0.5 kg/min

(300 kPa)

Condensate 1/2" (15 mm) female

Loading...

Loading...