Gianneschi Pumps and Blowers s.r.l.

Tel: +39 0584 365101 Fax: +39 0584 969411

www.gianneschi.net

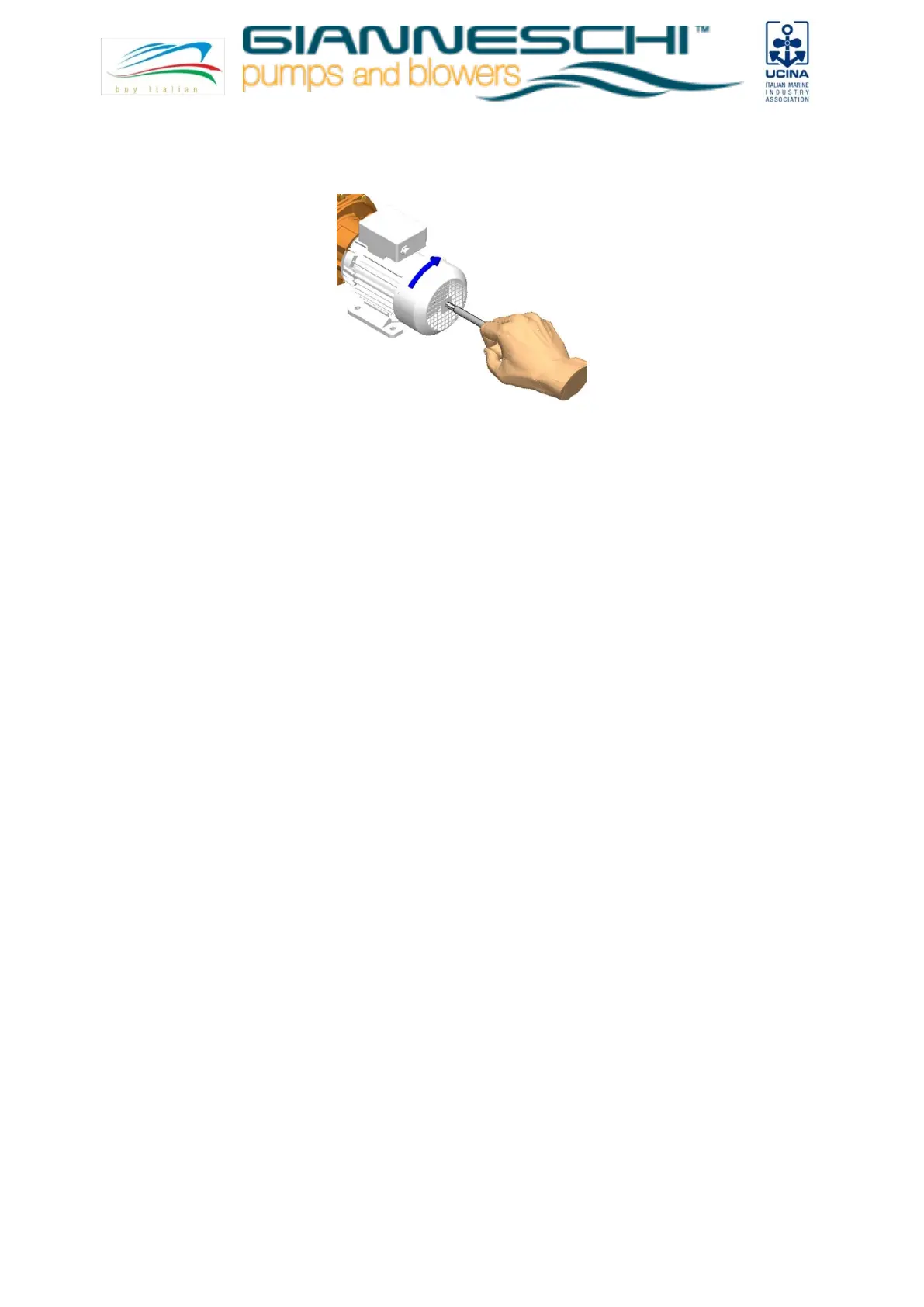

Check that the shaft turns by hand. For this purpose the pumps have a screwdriver notch on the ventilation

side of the shaft end.

With a three-phase motor check that the direction of rotation is as shown by the arrow on the pump casing,

otherwise disconnect electrical power and reverse the connections of two phases.

Check that the pump works within its field of performance, and that the absorbed current shown on the

name-plate is not exceeded. Otherwise adjust the delivery gate valve or the setting of any pressure switches.

6. Maintenance

When the pump is not used, empty it completely if freezing may be expected. If the pump has been

used for unclean liquids, flush the pump with clean water before draining.

Before restarting the unit, check that the shaft is not jammed and fill the pump casing completely with liquid.

Disconnect electrical power before any servicing operation and make sure the pump cannot be accidentally

switched on.

7. Dismantling

Close the suction and delivery gate valves and drain the pump casing before dismantling the pump. For

dismantling and re-assembly see construction in the cross section drawing.

8. Spare parts

When ordering spare parts, please quote data stamped on the name-plate and the position number of each

spare part required in accordance with the cross section drawing. Use bearings with C3 clearance and

grease for high temperatures.

Any pumps that require inspection/repair must be drained and carefully cleaned inside and out-side

before dispatch/submission.

Changes reserved.

Loading...

Loading...