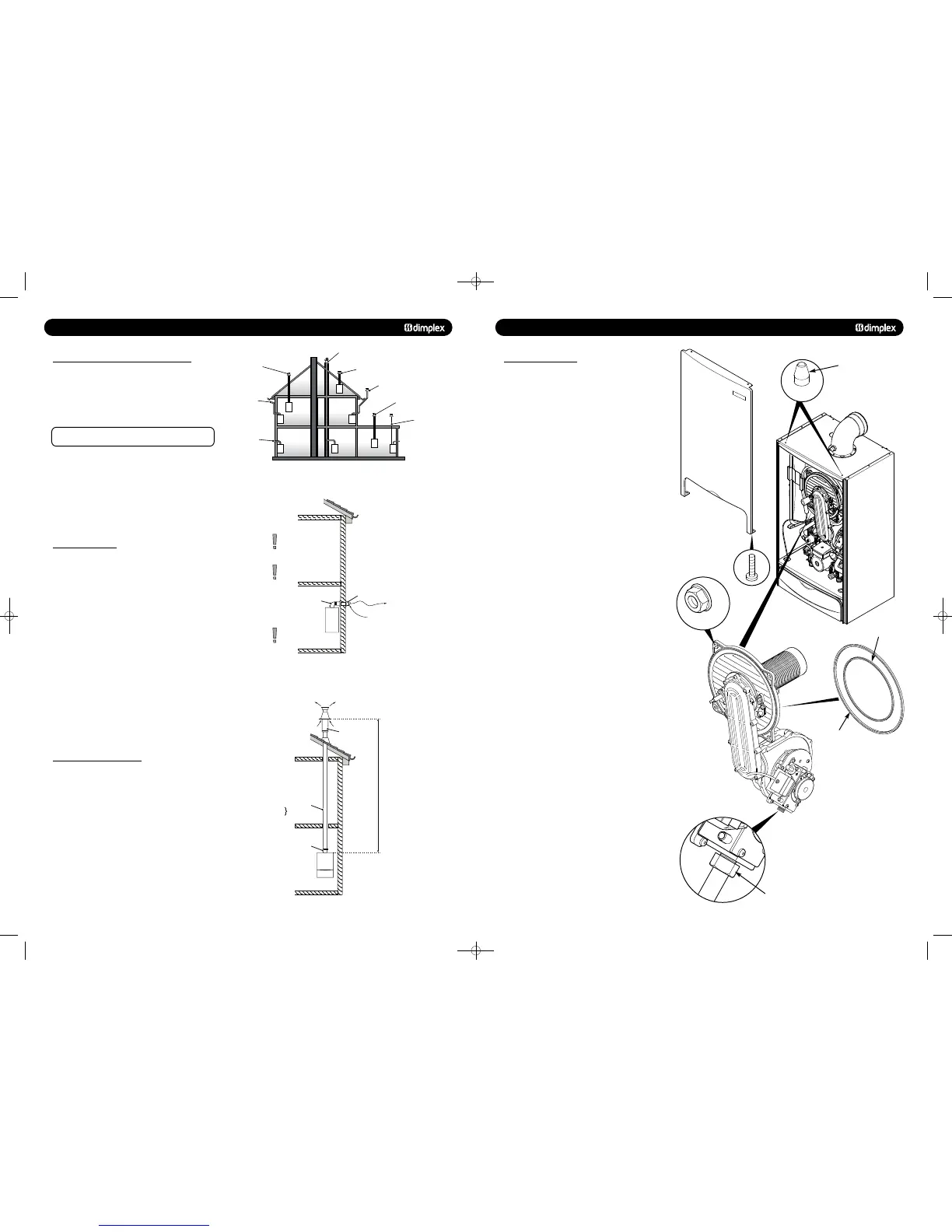

8.0 FLUE OPTIONS

8.1 CONCENTRIC AIR/FLUE DUCT SPECIFICATIONS

The Dimplex Combi 24, Dimplex Combi 30 and Dimplex Combi

38 can be installed to a number of different concentric flue

systems. The different flue applications as shown in Fig. 20 are

available as kits comprising the connecting parts to the

appliance and end terminal. Flue extension ducts and extension

elbows are available as accessories.

Dimplex Combi 38 only, with maximum concentric

flue length of 10m, the heat input will be reduced by 6.1%

8.2 Kit A + Telescopic Horizontal Wall Terminal

(C13) - Part No. 956120

Traditional concentric flue system, Fig. 21, with a maximum

length of 10000mm. The flanged flue elbow is designed with a

3° slope towards the appliance so that the condensate can

easily drain off. It has to be considered that for every metre

horizontal flue length the terminal exit centreline is approx.

45 mm higher than the elbow’s centreline.

The standard telescopic terminal is 615mm max length and

430mm min length, but can be cut to a minimum flue length of

250mm, which is suitable for single, 100mm (4”), brick walls.

8.3 Kit B Vertical Concentric Flue Terminal

(C33) - HBL Part 956081

Standard concentric (100/60) vertical flue application, Fig. 22,

through roof attics with a maximum length of 12000mm.

The kit comprises of the roof terminal, flashing kit, vertical

adaptor with sampling point and bracket.

The maximum length is measured from the top of the

appliance casing to the underside of the air cowl.

For installation details refer to the flue kit instructions.

Chimney flue liner kit

- Part no. 956082

Vertical flue kit - Part no. 956081

Vertical flue kit - Part no. 956081

with flat roof flashing plate

Split pipe vertical flue outlet kit

- Part no. 956080

with flat roof flashing plate

Raised external flue outlet kit

- Part no. 956084

Vertical flue kit - Part no. 956081

External vertical flue kit

- Part no. 956085

Standard telescopic

horizontal flue kit

- Part no. 956120

Flue system application

The pluming from the flue may

cause nuisance to neighbours

or other buildings.

60/100 flue accessories:

0.5m flue extension duct - 956092

1m flue extension duct - 956093

93 flue extension elbow - 956091

45 flue extension elbow (2x) - 956090

Vertical flue turret - 956087

Ø60/100mm concentric

standard horizontal wall

terminal.

Max. length 10,000mm.

Min. length 250mm.

Standard telescopic horizontal flue kit - Part no. 956120

Horizontal terminal has a

built-in fall in the flue to allow

condensate to drain away.

If horizontal flue requires

extension pipe. the flue

should be installed such

that there is no section less than

2.5° - 3° to the horizontal,

falling back towards the boiler.

93 flanged elbow (concentric)

with sampling point

Kit A +

Vertical flue kit - Part no. 956081

Suitable for 25 - 45°

Pitch Angle

Length

Kit B

60/100 flue accessories:

0.5m flue extension duct - 956092

1m flue extension duct - 956093

93 flue extension elbow - 956091

45 flue extension elbow (2x) - 956090

Flat roof flashing plate - 840512

93 flanged flue elbow - 956086

Max. length12m.

Min. length 0.6m.

Roof terminal

with rain cover

and pitched roof

flashing kit.

Vertical flue socket

with sampling point.

Top of Boiler

to underside of Cowl

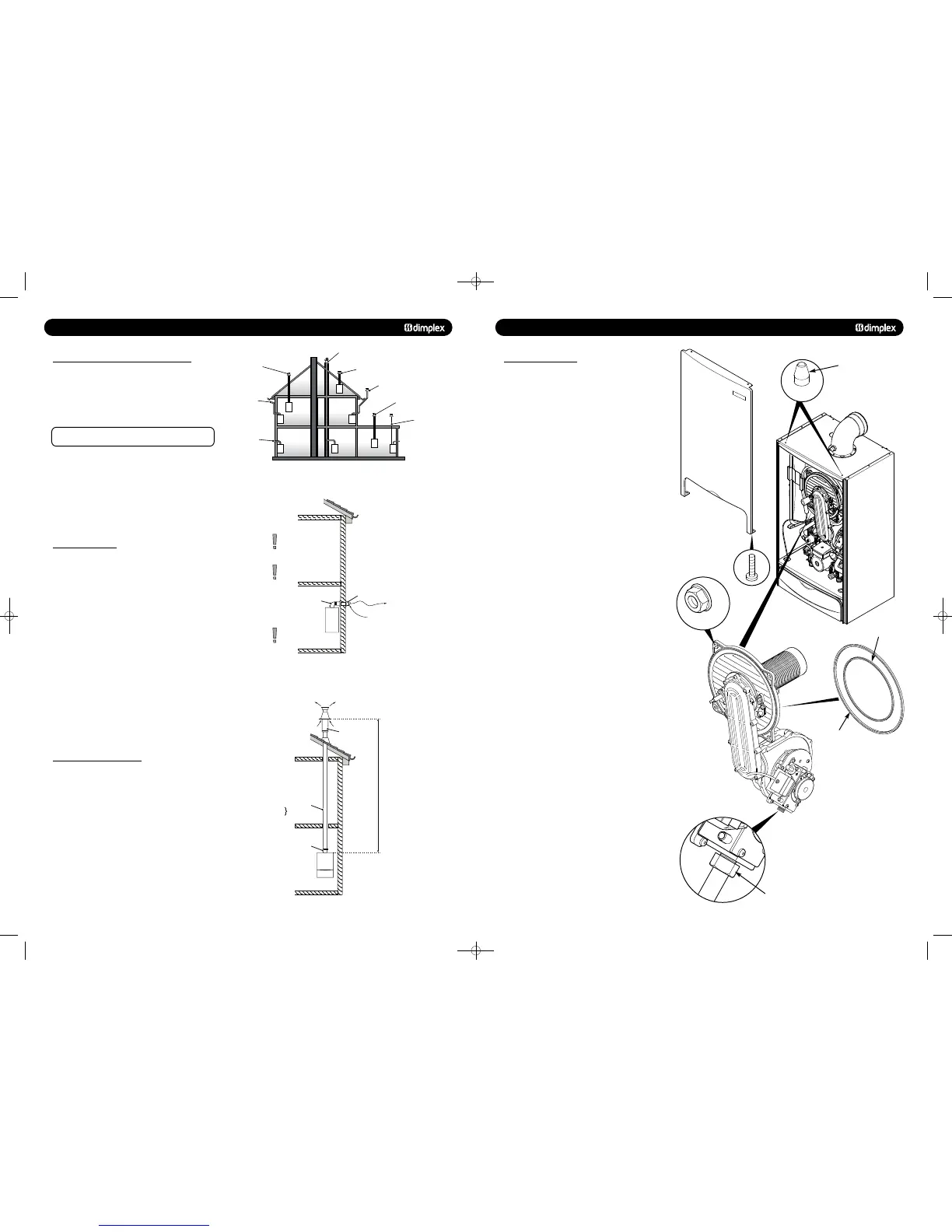

12.0 SERVICING AND MAINTENANCE

12.1 ANNUAL SERVICING

8. Remove the two screws securing the front panel to the

underside of the boiler. Lift the panel upwards off its retaining

studs on top of the appliance.

9. Disconnect the two leads to the fan and one lead to the gas

valve.

10. Undo the nut on the gas inlet pipe to the valve and retain

the sealing washer.

11. Remove the four nuts holding the burner door plate and

remove the valve and fan assembly (Fig. 51).

12. Clean any debris from the heat exchanger using a soft

brush and check that the gaps between the tubes are clear.

13. Inspect the burner, electrode positions and insulation,

cleaning or replacing if necessary.

14. Check the condition of the burner door seals, replacing if

necessary.

15. Reassemble in reverse order.

16. Complete the relevant Service Interval Record section of

the Benchmark Commissioning Checklist at the rear of this

publication and then hand it back to the user.

© Dimplex Boilers 2008

Fig. 51

Fig. 49

Fig. 50

Fig. 52

Gas Inlet Nut

Front Panel

Retaining Stud

Burner Door Seal

Inner Seal

48pp MANUAL SPREADS 19/10/10 08:36 Page 18

Loading...

Loading...