GENERAL INFORMATION OA-5

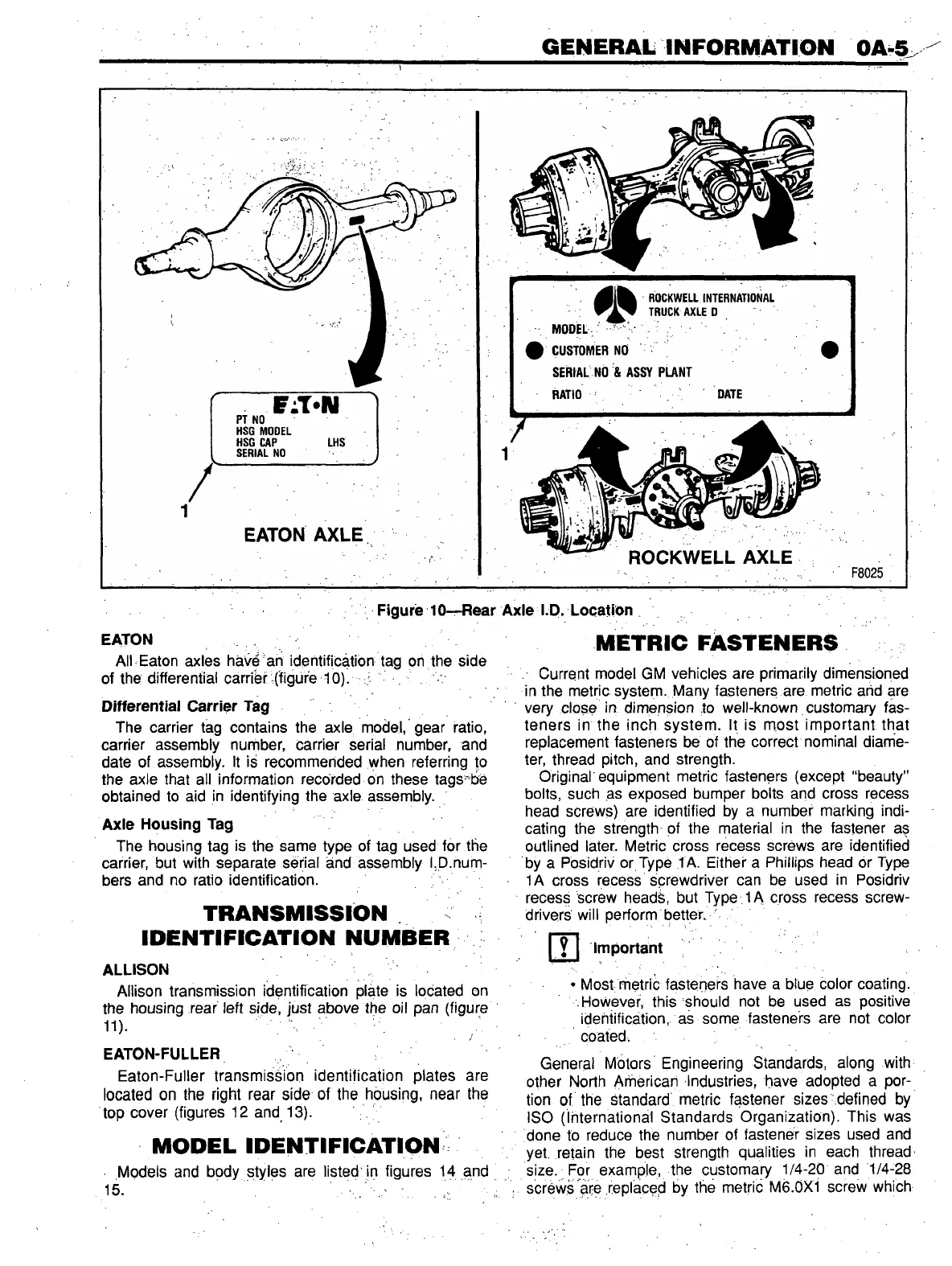

Figure 10—Rear Axle I.D. Location

EATON METRIC FASTENERS

All Eaton axles have an identification tag on the side

of the differential carrier (figure 10).

Differential Carrier Tag

The carrier tag contains the axle model, gear ratio,

carrier assembly number, carrier serial number, and

date of assembly. It is recommended when referring to

the axle that all information recorded on these tags be

obtained to aid in identifying the axle assembly.

Axle Housing Tag

The housing tag is the same type of tag used for the

carrier, but with separate serial and assembly I.D.num

bers and no ratio identification.

TRANSMISSION

IDENTIFICATION NUMBER

ALLISON

Allison transmission identification plate is located on

the housing rear left side, just above the oil pan (figure

11).

Current model GM vehicles are primarily dimensioned

in the metric system. Many fasteners are metric and are

very close in dimension to well-known customary fas

teners in the inch system. It is most important that

replacement fasteners be of the correct nominal diame

ter, thread pitch, and strength.

Original equipment metric fasteners (except “beauty”

bolts, such as exposed bumper bolts and cross recess

head screws) are identified by a number marking indi

cating the strength of the material in the fastener as

outlined later. Metric cross recess screws are identified

by a Posidriv or Type ,1A. Either a Phillips head or Type

1A cross recess screwdriver can be used in Posidriv

recess screw heads, but Type 1A cross recess screw

drivers will perform better.

Important

• Most metric fasteners have a blue color coating.

However, this should not be used as positive

identification, as some fasteners are not color

coated.

EATON-FULLER

Eaton-Fuller transmission identification plates are

located on the right rear side of the housing, near the

top cover (figures 12 and 13).

MODEL IDENTIFICATION

Models and body styles are listed in figures 14 and

15. ’ ' . 7 " ' - ■

General Motors Engineering Standards, along with

other North American Industries, have adopted a por

tion of the Standard metric fastener sizes defined by

ISO (International Standards Organization). This was

'done to reduce the number of fastener sizes used and

yet .retain the best strength qualities in each thread

size. For example, the customary 1/4-20 and 1/4-28

screws are replaced by the metric M6.0X1 screw which

Loading...

Loading...