6A2-12 VS ENGINES, GASOLINE

133 ; 134

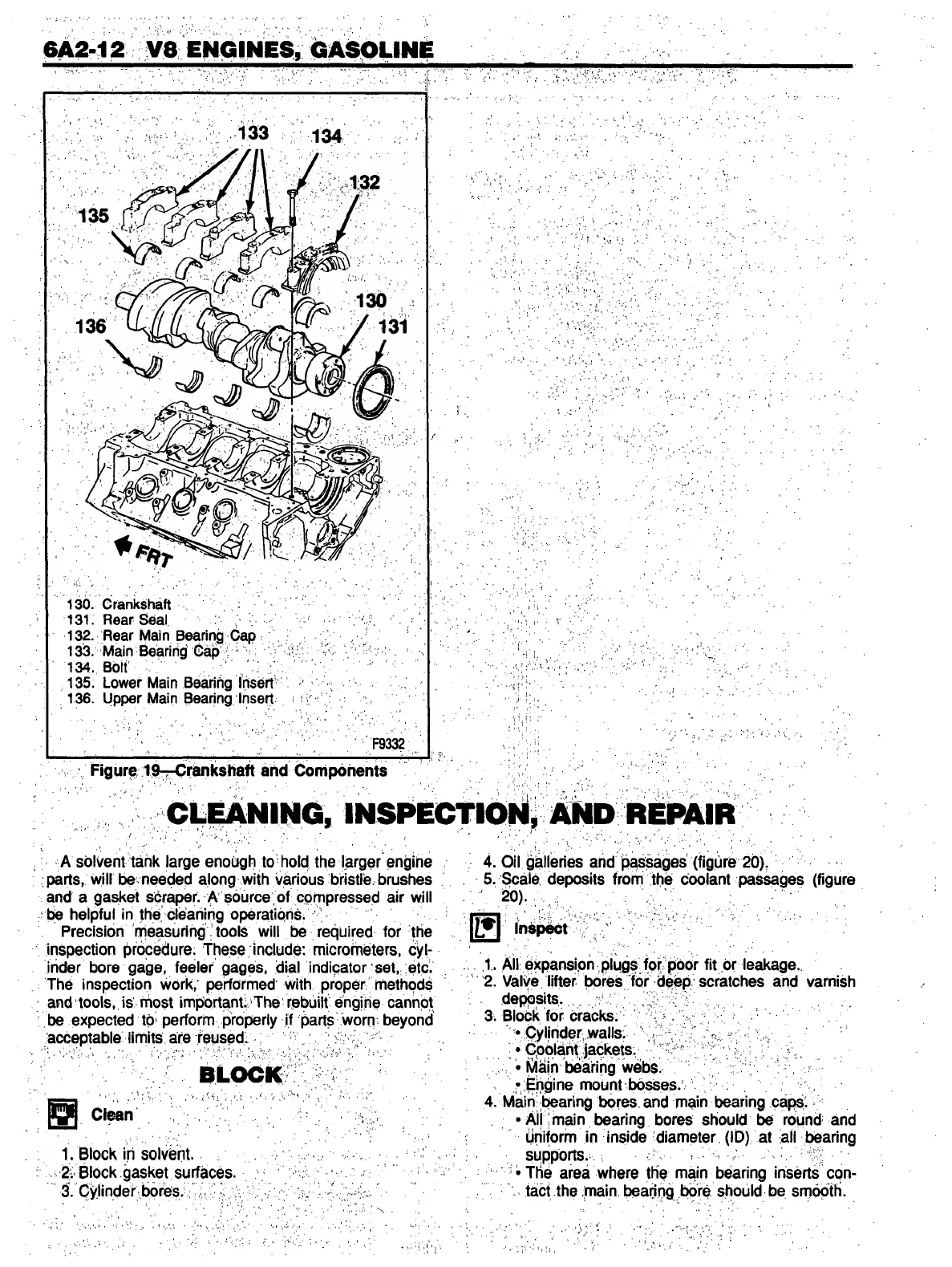

130. Crankshaft

131. Rear Seal

132. Rear Main Bearing Cap

133. Main Bearing' Cap

134. Bolt

135. Lower Main Bearing Insert

136. Upper Main Bearing Insert

F9332

CLEANING, INSPECTION^ A N DItEm U R

; parts, will be needed along with various bristle, brushes

and a gasket scraper A source,of compressed air will

be helpful in the cleaning operations:

Precision measuring ! tools will be required for the

inspection procedure. These include: micrometers, cyl

inder bore gage, feeler gages, dial indicator set, etc.

The inspection work, performed with proper methods

and tools, is most important; The rebuilt engine cannot

be expected to perform properly if parts worn beyond

acceptable limits are reused.

BLOCK

Clean

1. Block in solvent.

£ Block gasket surfaces.

3. Cylinder bores. !; v

4.

5. Scale deposits from the coolant passages (figure

■\ so).

L*

I n s p e c t

,1, All expansion plugs for poor fit or leakage.

2. Valve lifter bores for deep scratches and varnish

deposits.. . ^

3. Block for cracks.

• Cylinder walls. N

• Coolant jackets.

• Main bearing webs.

• Engine mount bosses.

4. Main bearing bores and main bearing caps. ;

• All main bearing bores should be round and

Uniform in inside diameter (ID) at all bearing

supports.

• The area where the main bearing inserts con

tact the main bearing bore should be smooth.

Loading...

Loading...