V8 ENGINES, GASOLINE 6A2-13

227

222

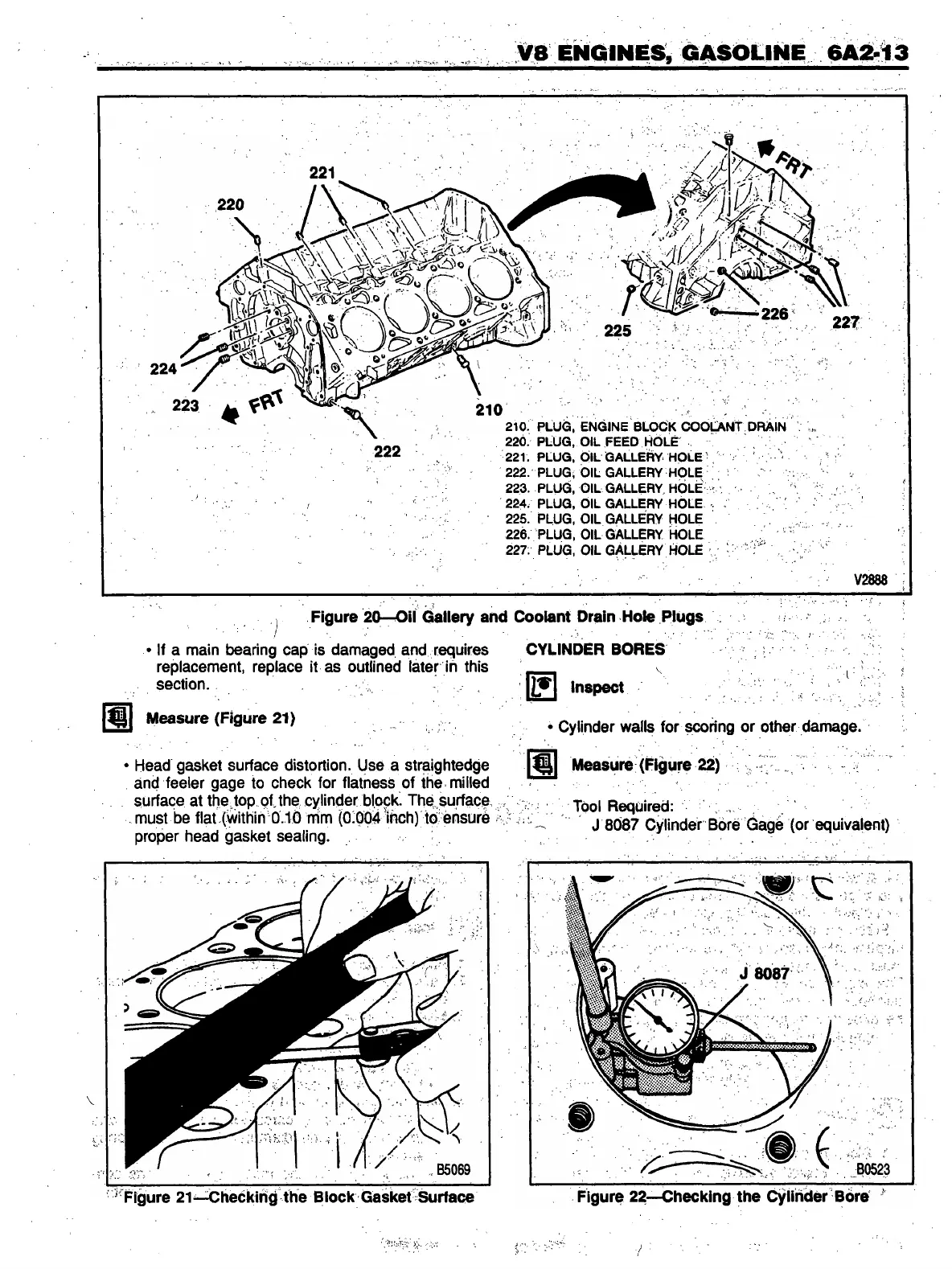

210. PLUG, ENGINE BLOCK COOLANT DRAIN

220. PLUG, OIL FEED HOLE

221. PLUG, OIL GALLERY HOLE

222. PLUG; OIL GALLERY HOLE

223. PLUG, OIL GALLERY HOLE

224. PLUG, OIL GALLERY HOLE .

225. PLUG, OIL GALLERY HOLE

226. PLUG, OIL GALLERY HOLE

227; PLUG, OIL GALLERY HOLE

V2888

F i g u r e 2 0 — O i l G a l l e r y a n d C o o l a n t D r a i n H o l e P l u g s

• If a main bearing cap is damaged and requires

replacement, replace it as outlined later in this

section.

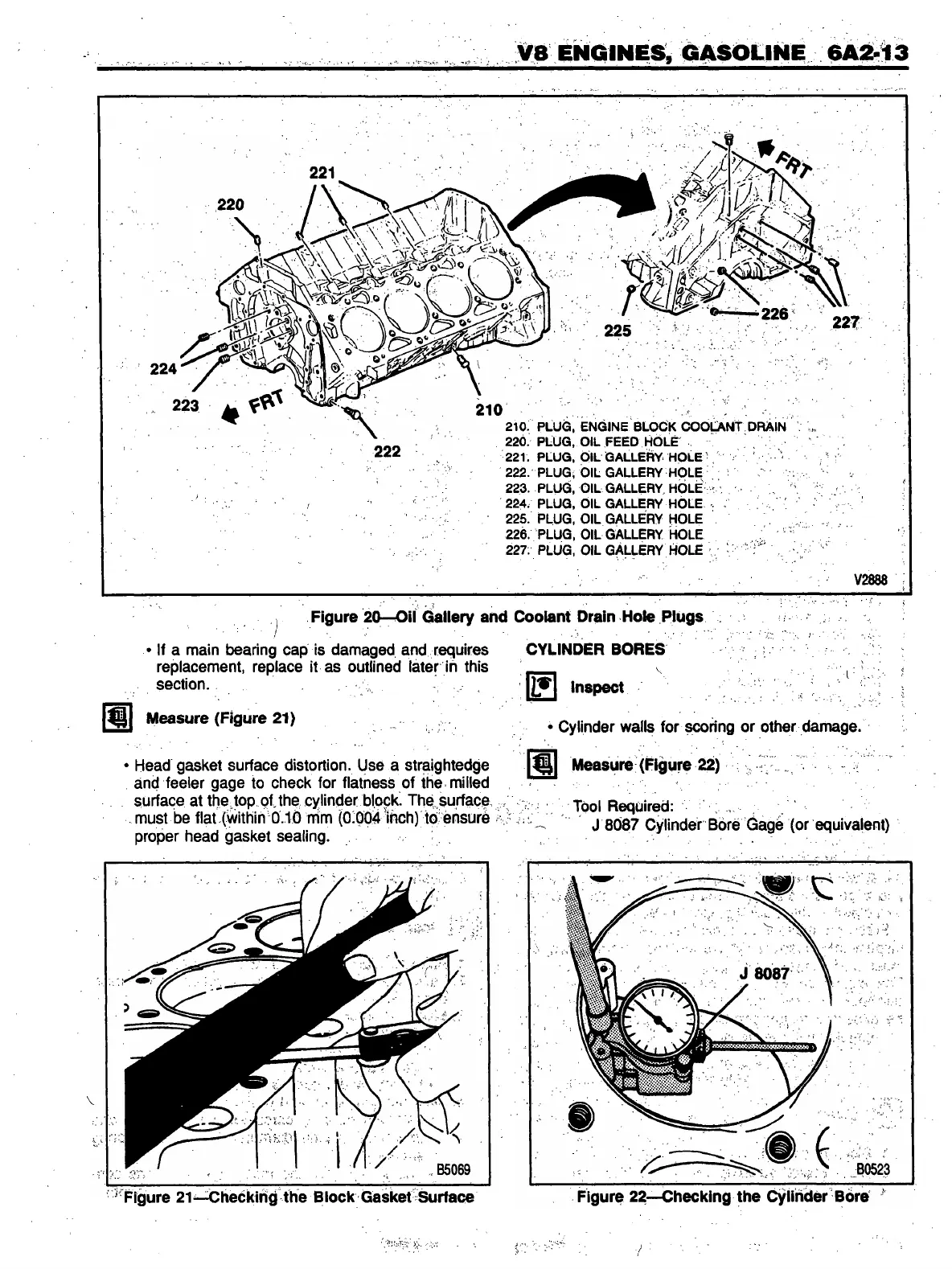

M e a s u r e ( F i g u r e 2 1 )

Head gasket surface distortion. Use a straightedge

and feeler gage to check for flatness of the milled

surface at the top ot the cylinder block. The surface

must be flat (within 0.10 trim (0.004 inch) to ensure

proper head gasket sealing.

C Y L I N D E R B O R E S

I n s p e c t • '

• Cylinder walls for scoring or other damage.

M e a s u r e ( F i g u r e 2 2 )

1

Tool Required:

J 8087 Cylinder Bore Gage (or equivalent)

Figure 21—Checking the Block Gasket Surface

■/

Loading...

Loading...