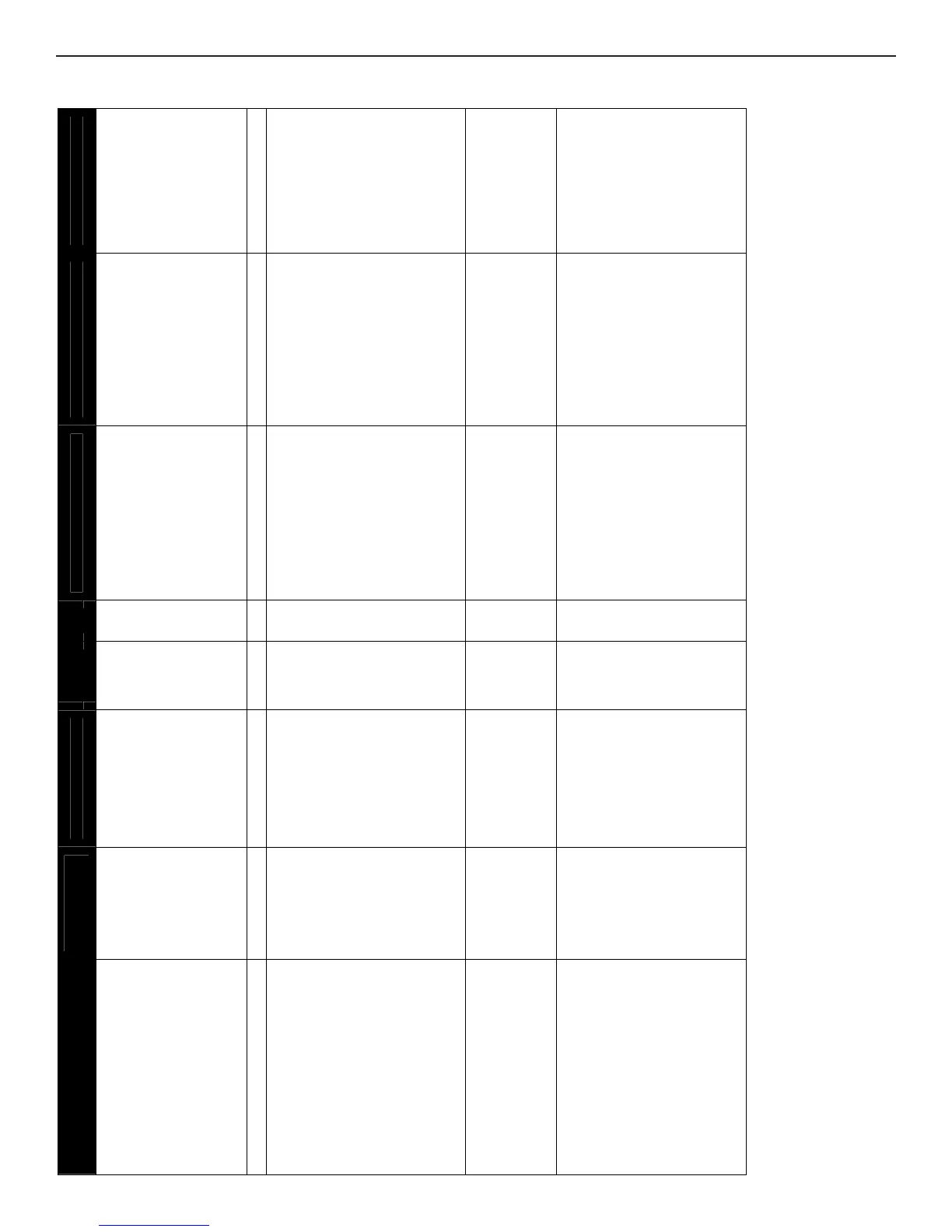

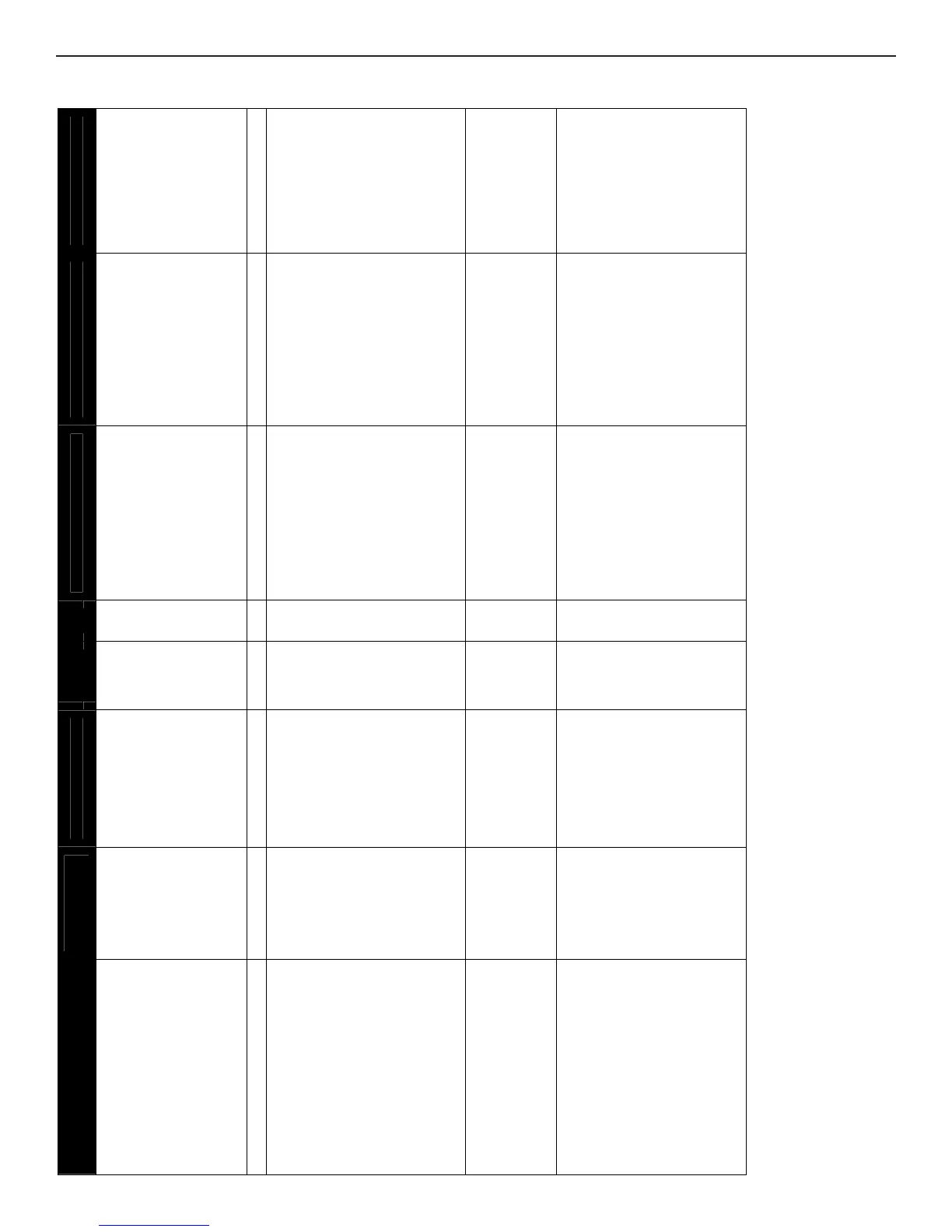

53

T

ROUBLESHOOTING

C

ODES

ComfortNet

Thermostat Only

Symptoms of Abnormal Operation

(Non-communicating & ComfortNet™

Thermostat)

Diagnostic/Status

LED Codes

Fault Description

Message Code

Possible Causes

Corrective Actions

Notes & Cautions

x Furnace fails to operate

x Integrated control module LED display

provides no signal.

x ComfortNet thermostat “Call for Service”

icon illuminated

x ComfortNet thermostat scrolls “Check

Furnace” message

if

x No 115 power to furnace

or no 24 volt power to

integrated control

module

x Blown fuse or circuit

breaker. Reverse

polarity.

x Integrated control

module has an internal

fault

INTERNAL

FAULT

EE

x Manual disconnect switch OFF,

door switch open or 24 volt wire

improperly connected or loose

x Blown fuse or circuit breaker

x Integrated control module has an

internal fault

x Assure 115 and 24 volt power to

furnace and integrated control

module.

x Check integrated control module

fuse (3A). Replace if necessary.

Correct polarity of line voltage

wires.

x Check for possible shorts in 115

and 24 volt circuits. Repair as

necessary.

x Replace bad integrated control

module.

x Turn power OFF prior to

repair.

x Replace integrated control

module fuse with 3A

automotive fuse.

x Read precautions in

“Electrostatic Discharge”

section of manual.

x Replace integrated control

module with current

replacement parts.

x LED display indicates

n

On

x Normal operation

None None

x Normal operation x None x Normal operation

x Furnace fails to operate

x Integrated control module LED display

provides

error code.

x ComfortNet thermostat “Call for Service”

icon illuminated.

x ComfortNet thermostat scrolls “Check

Furnace” message.

E0

x Furnace lockout due to

an excessive number of

ignition “retries” (3 total)

LOCKOUT E0

x Failure to establish flame. Cause

may be no gas to burners, front

cover pressure switch stuck open,

bad igniter or igniter alignment,

improper orifices, or

coated/oxidized or improperly

connected flame sensor.

x Loss of flame after establishment.

Cause may be interrupted gas

supply, lazy burner flames

(improper gas pressure or

restriction in flue and/or

combustion air piping), front

cover pressure switch opening, or

improper induced draft blower

performance.

x Locate and correct gas

interruption.

x Check front cover pressure

switch operation (hose, wiring,

contact operation). Correct if

necessary. Make sure furnace is

draining properly.

x Replace or realign igniter.

x Check flame sense signal. Sand

sensor if coated and/or oxidized.

x Check flue piping for blockage,

proper length, elbows, and

termination.

x Verify proper induced draft

blower performance.

x Turn power OFF prior to

repair.

x Igniter is fragile, handle

with care.

x Clean flame rod with steel

wool.

x See “Vent/Flue Pipe”

section for piping details.

x Furnace fails to operate.

x Integrated control module LED display

provides

error code.

x ComfortNet thermostat “Call for Service”

icon illuminated.

x ComfortNet thermostat scrolls “Check

Furnace” message.

E1

x Low stage pressure

switch circuit is closed at

start of heating cycle.

PS1

CLOSED

E1

x Low stage pressure switch

contacts sticking.

x Shorts in pressure switch circuit

wiring.

x Replace low stage pressure

switch.

x Repair short in wiring.

x Turn power OFF prior to

repair.

x Replace pressure switch

with correct replacement

part.

x Induced draft blower runs continuously

with no further furnace operation.

x Integrated control module LED display

provides

error code.

x ComfortNet thermostat “Call for Service”

icon illuminated.

x ComfortNet thermostat scrolls “Check

Furnace” message.

E2

x Low stage pressure

switch circuit is not

closed.

PS1 OPEN E2

x Pressure switch hose blocked

pinched, or connected improperly.

x Blocked flue and/or inlet air pipe,

blocked drain system or weak

induced draft blower.

x Incorrect pressure switch set point

or malfunctioning switch

contacts.

x Loose or improperly connected

wiring.

x Inducer not running.

x H fitting atmospheric port

blocked.

x Inspect pressure switch hose.

Repair/replace if necessary.

x Inspect flue and/or inlet air

piping for blockage, proper

length, elbows, and termination.

x Check drain system. Correct as

necessary.

x Check induced draft blower

performance. Correct as

necessary.

x Correct pressure switch set point

or contact motion.

x Tighten or correct wiring

connection.

x Clean H fitting.

x Turn power OFF prior to

repair.

x Replace pressure switch

with correct replacement

part.

x Replace induced draft

blower with correct

replacement part.

x Take care to

assemble/install H fitting

in factory configuration.

Loading...

Loading...