STEP 2 - HANGER INSTALLATION

Top Hanger Assemblies

2.1 Mark top hanger placement on the building support

beams and runway/monorail track (refer to the General

Arrangement Drawing, inserted in this manual, for

hanger placement). Installation parameters can be

found on page 22.

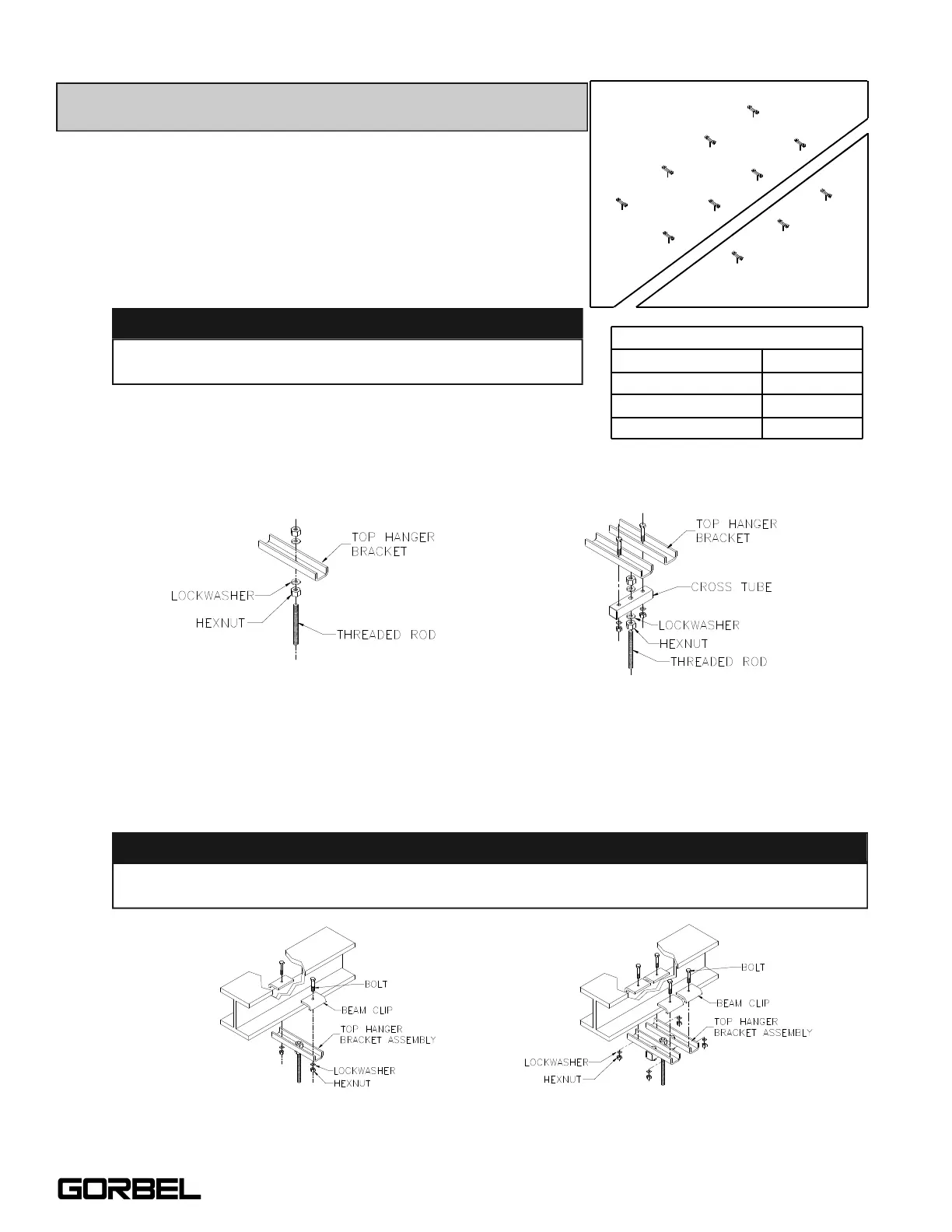

2.2 To attach threaded rod to top hanger bracket:

Assemble top hanger assembly (diagram 2A). Refer to

Chart 2A for proper nut torque.

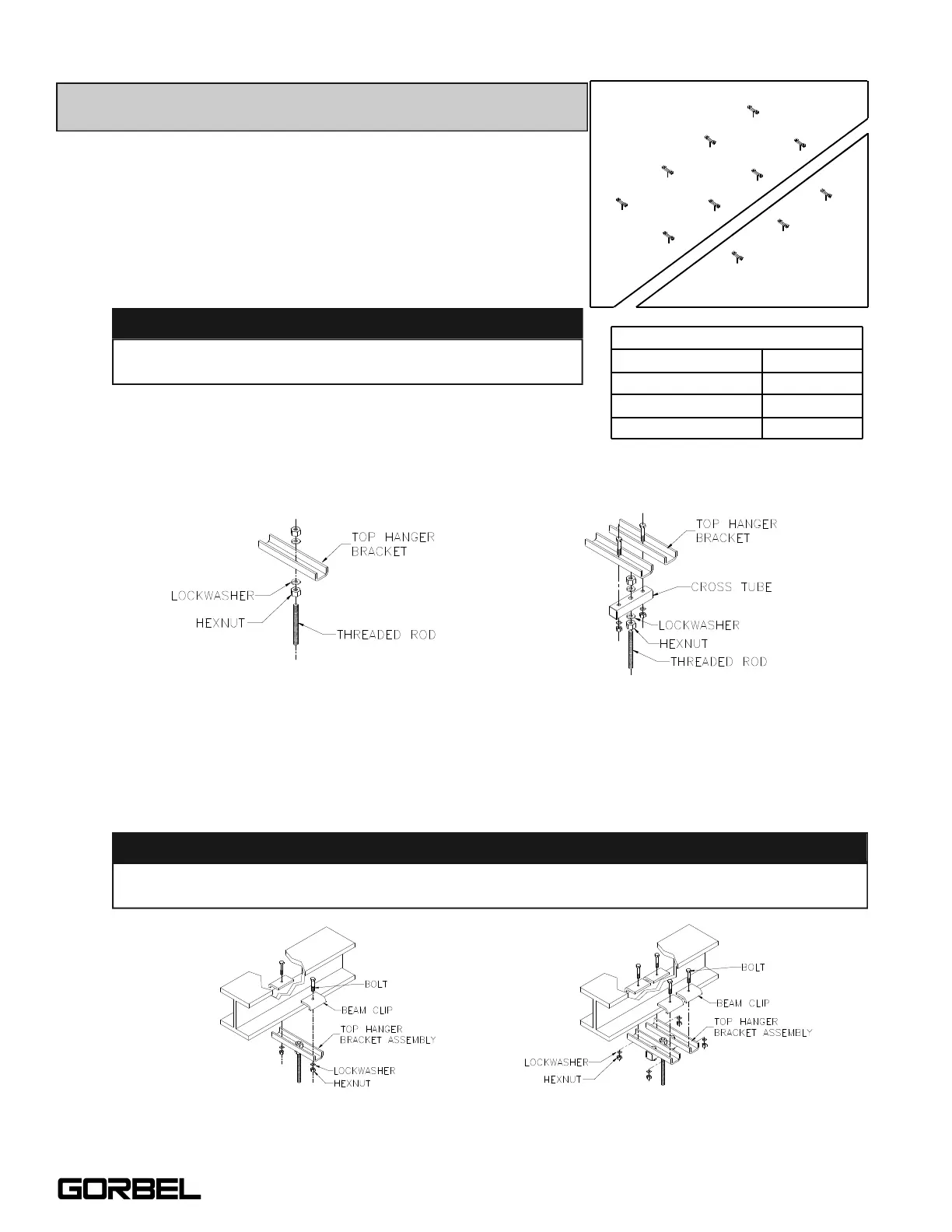

2.3 Bolt top hanger bracket assembly and beam clips to building support beam

(diagram 2B). Note: Flange thickness may vary and require shimming. Shimming

may be needed to assure that the beam clip hardware is vertical.

TIP: Standard top hanger brackets are designed for flange

widths from 1”-3”, 3-1/4”-5-1/4”, 5-1/2”-7-1/2”, 8”-10”.

WARNING

Threaded rod must have a minimum of two threads

beyond the hexnut.

Chart 2A. Torque Chart.

4000#250-2000#

Diagram 2A. Attaching threaded rod to top hanger bracket.

WARNING

250-2000# 4000#

Diagram 2B. Bolting top hanger bracket and beam clips to existing support beam.

2

9/05

“Center hole” of the top hanger bracket assembly must be centered on building support

beam.

Bridge Crane

Monorail

Bolt Diameter

1/2”

5/8”

3/4”

Torque

50 ft.-lb.

95 ft.-lb.

150 ft.lb.

TORQUE CHART

Loading...

Loading...