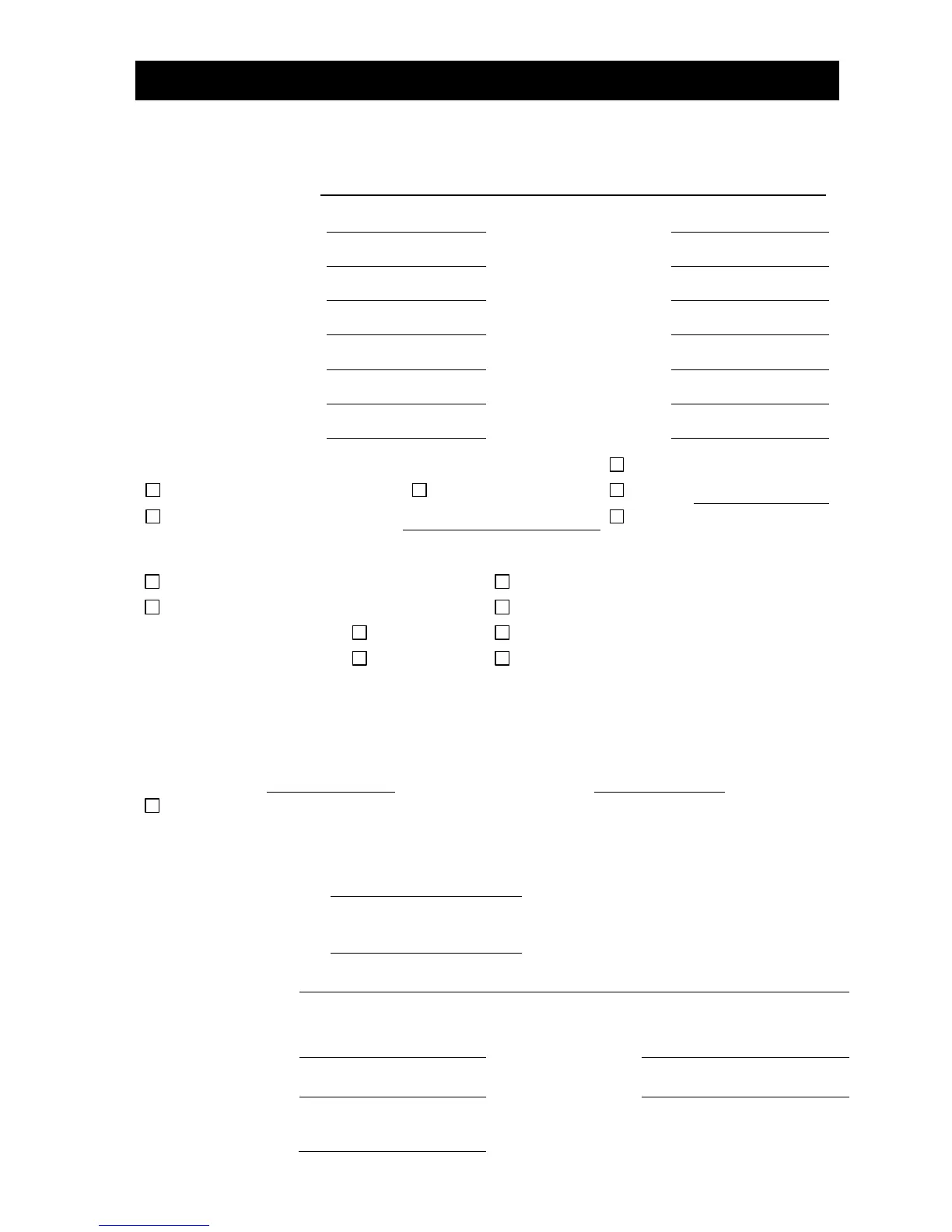

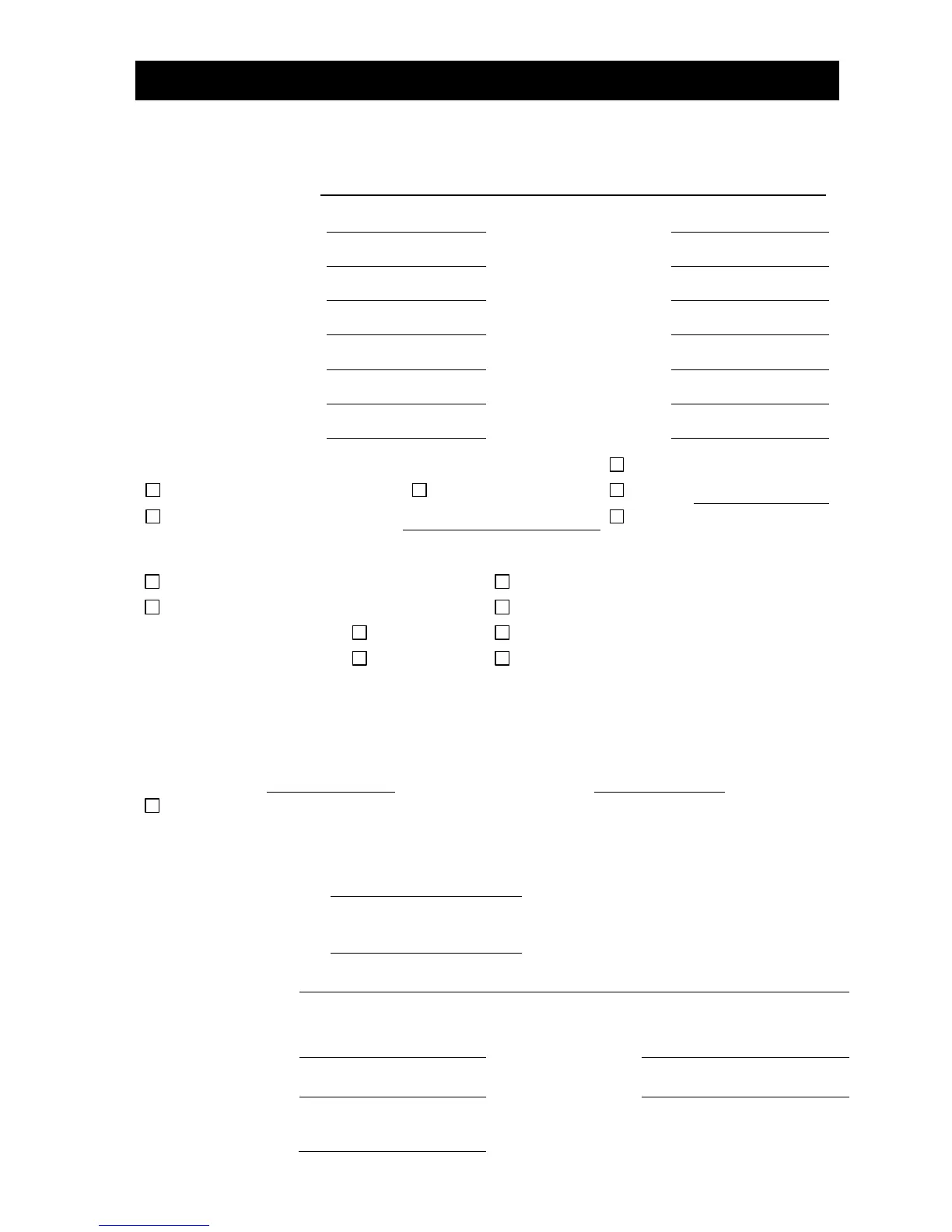

12. Maintenance log for GRAF small wastewater treatment systems

37 / 40

12. Maintenance log for GRAF small wastewater treatment systems

Will the system process commercial wastewater too?

Restaurant without kitchen

Grease separator present, NG

Function check of system parts important to operation:

Aeration / valve 1 (blue)

Discharge lifter / valve 2 (black)

Excess sludge lifter / valve 3 (white)

intensive, circulation clearly visible

Aerator pattern / aeration:

Sludge accumulator + buffer:

The operator should arrange for the cesspit to be emptied.

mg/l (normally approx. 4-6 mg/l, at least 2 mg/l)

Sludge as proportion of

volume:

Excess sludge reservoir

(valve 3):

Loading...

Loading...