Repair manual GRAMMER seat suspension MSG95EAC – November 2012

Material no. 1 277 338

2.3 Troubleshooting – Locating the fault

Page 1 of 15

Preconditions for fault diagnosis for each test:

• The individual functions are activated in compliance with the instructions of the seat operating instructions.

• The electrical system of the vehicle has been inspected and found to be OK in compliance with the vehicle operating instructions.

• The electrical connections (STVB) have been inspected with regard to continuity and corrosion and found to be OK; they have been manufactured properly and are locked, if

possible.

• Cable harness for seat suspension has been inspected with regard to arcing spots and broken leads (kinks) and found to be OK.

• The seat suspension is disconnected (no voltage that might cause a current flow must be applied to the seat suspension).

• Bellows at the upper suspension part removed (see Chapter 3.4) and pressed down.

Notes: • The components stated above are illustrated in Chapter 2.1.

• Descriptions of the work required during the diagnosis can be found in Chapter 3.

• Repeat the inspection after replacement of defective components.

• Assemble the seat after the end of the inspection or before repeating the inspection (e.g. reconnecting electrical connections (STVB)).

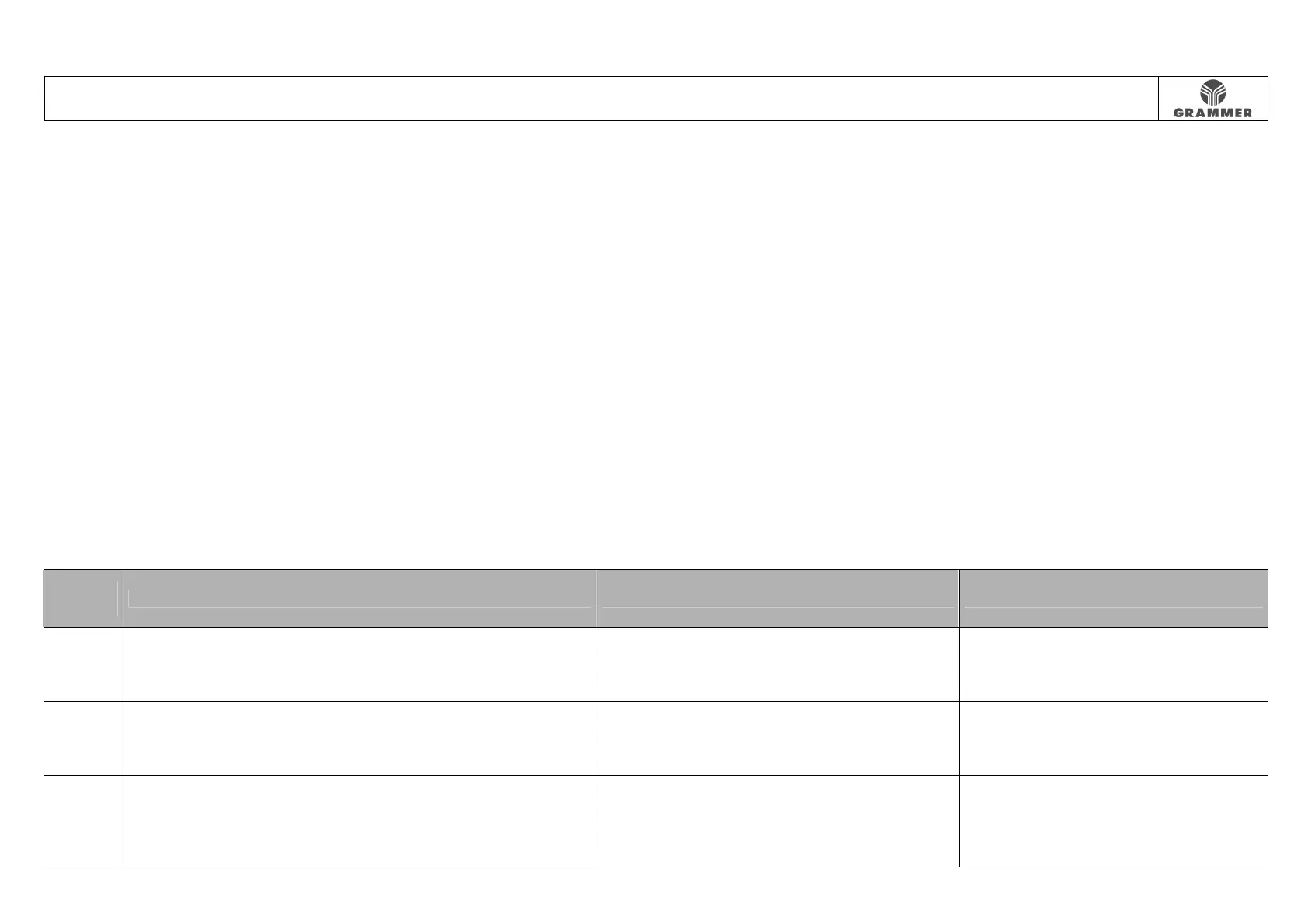

1 Inspection of air spring and air distributor

Preconditions for fault diagnosis:

• See “Preconditions for fault diagnosis for each test”.

• Air hoses and air intake and exhaust hose have been inspected with regard to kinks and tightness and found to be OK.

Step

no.

Inspect/operate Result/Specified status Troubleshooting

1.1 Check the air spring for abrasion. Visible abrasion, air spring is leaky.

No abrasion.

Replace air spring (see Chapter 3.10).

Proceed with inspection step no. 1.2.

1.2 Apply load to the seat suspension. Air escapes at the air spring.

The air spring is airtight.

Replace air spring (see Chapter 3.10).

Proceed with inspection step no. 1.3.

1.3 Apply load to the seat suspension. Air escapes at the air distributor.

The air distributor is airtight.

Replace the air distributor (see Chapter

3.14).

End of inspection.

Loading...

Loading...