27

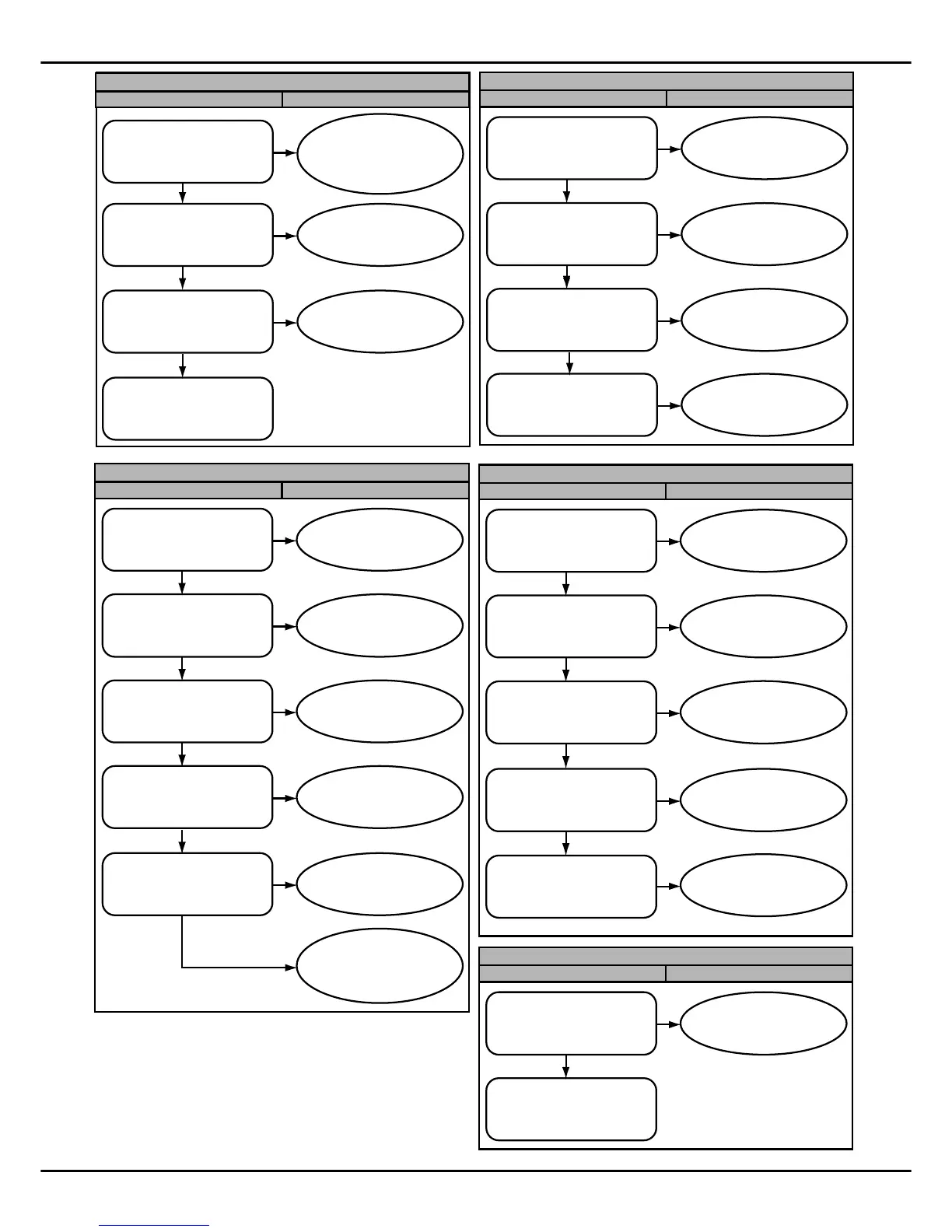

Eb/E6 (DC fan motor fault (for 4860))

Diagnosis Handling

Check whether motor wiring is

reliably connected according to

the wiring diagram

Yes

Check whether outdoor unit

air return is blocked

No

Reseat the wiring

according to wiring

diagram

No

Remove all the barriers

Check whether there’s 15V DC

between the test points P8 and

P2

Check whether wiring is

correct, replace the main

control board

Yes

No

Yes

Replace the motor to check

whether it is normal after

restart

Replace the main control

board

No

This fault is caused by strong

interference form electricity

grid.Unit will recovery when

electricity grid is normal.

E9 (EEPROM chip fault)

Diagnosis

Handling

Power off and then power on

to see whether it is normal

Yes

Re-insert the EEPROM

chip or replace the main

control board

No

P8 (Hurricane protection of the DC fan motor (for 4860))

Diagnosis

Handling

Check whether there’s 15VDC

between terminals P8 and P2

Yes

Check whether P8 error code

is displad once motor stops.

No

Replace the motor

If wiring is correct, replace

the main control board

No

Insure motor is not influenced

by an external force when

stopped, e.g. wind. Reset

power.

Check whether the high speed

operating of fan motor was

caused by external force

e.g.wind.

No

Yes

Replace the main control

board

Yes

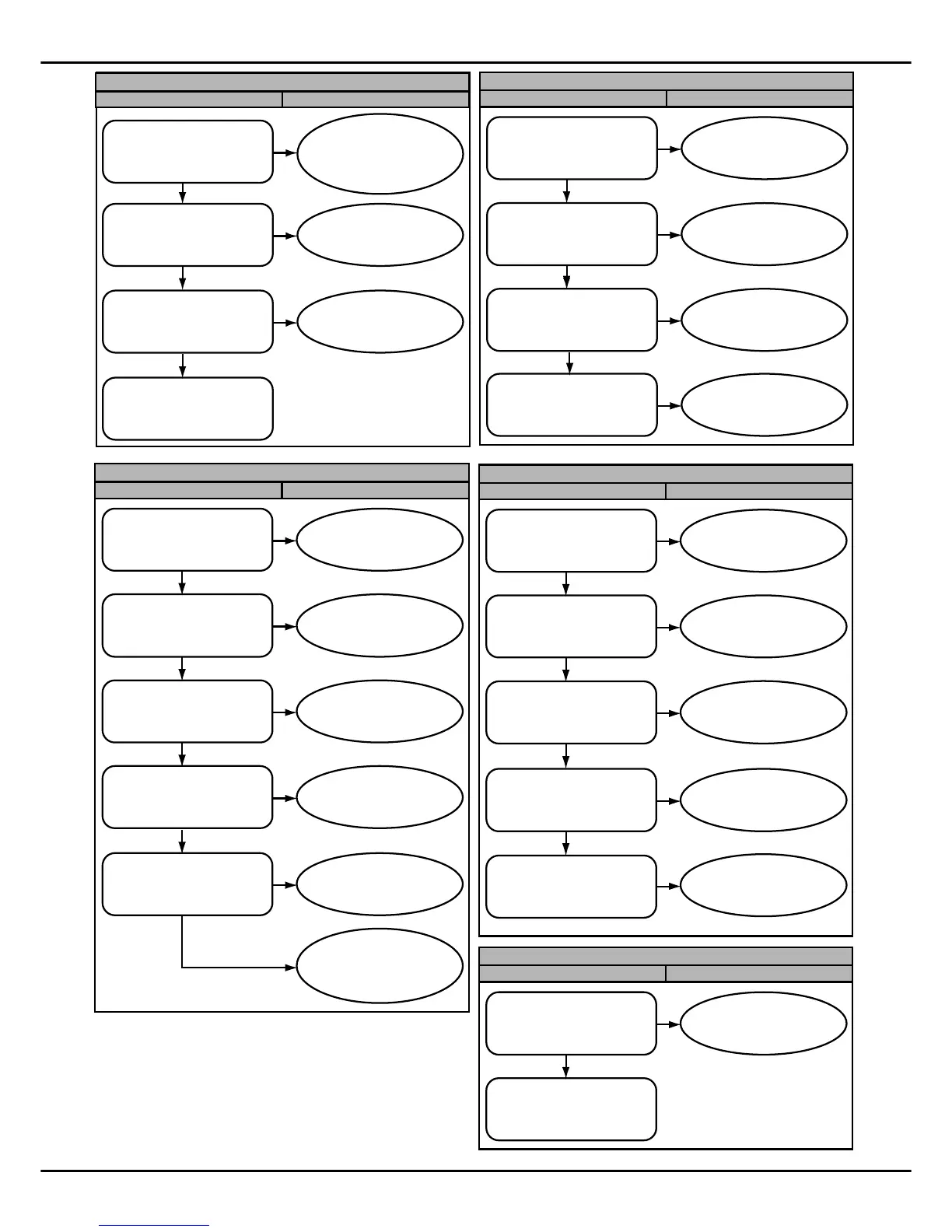

F4/P0 (High temperature protection of IPM radiator (Tf))

Diagnosis

Handling

Check whether the radiator is

damaged

No

Check whether there’s dust or

fallen leaves influencing

radiator

No

Check whether the fan and

motor can normally operate

Yes

Check whether resistance

of Tf is in the range of

TABLE 2

Yes

Power off and restart to

check whether there’s the

same fault

Fix the radiator. If

radiator is damaged,

replace it

Yes

Clean all the dust and

fallen leaves

Yes

Replace the fan and

motor

No

Replace Tf sensor

No

Replace the drive board

Yes

E5(Voltage protection)

Diagnosis Handling

Check whether the power

supply voltage is between

187-253 V

Yes

Check whether the power wires are

connected firmly, whether the power

supply wire diameter meets the

requirements from the manufacture

Yes

Cut off the power, and wait until

electronic control indicator goes out,

then power on to see whether the

compressor operates normally

Yes

Test whether there’s 380V DC

between the terminals P2 and

P4 when compressor is

running

Yes

Check whether there are

high voltage equipments

nearby.

Make sure the power

supply is within

correct range

No

Replace the power supply

wires or connect the power

supply wires well

No

Replace the main

control board

Replace the main

control board

No

Yes

Separate high-power

equipment and power supply

No

This fault is caused by power

supply voltage instantaneous

fluctuation. Restart when

power grid is normal

No

Loading...

Loading...