GB - 36

The fuel filter cannot be disassembled. If the

fuel filter becomes clogged, replace it with a

new one.

1. Park the machine safely in a well-

ventilated area.

2. Allow to cool.

3. Compress hose with clamp between

tank and filter. Use care not to damage

or puncture hose.

4. Disconnect the hose clamps (1) from the

fuel filter (see figure 25).

5. Slide the fuel line off of both ends of the

fuel filter (2).

6. Install the new fuel filter paying close

attention to the flow direction (3) noted

on the fuel filter.

7. Remove clamp.

The fuel pump can not be disassembled. If

the fuel pump fails, replace it with a new one.

SPARK PLUG SERVICE

Clean or replace the spark plug and reset the

gap every 100 hours of operation.

1. Disconnect the spark plug wire lead and

remove the spark plug.

2. Clean the electrodes by scraping with a

wire brush to remove carbon deposits.

3. Inspect for cracked porcelain or other

wear and damage. If any wear or

damage is evident, replace with a new

spark plug.

4. Check the spark plug gap and reset if

necessary. The correct gap should be

.030 inches (.75 mm). To change the

gap, bend only the side electrode using

a spark plug tool.

5. Install and tighten the spark plug to 22

N·m (16 ft. lbs.). Reconnect the spark

plug wire lead.

See the engine operator’s manual for the

recommended spark plug.

COOLING SYSTEM CLEANING

Before each use check to make sure the air

intake screen is free from grass and debris

and clean if necessary.

Every 100 hours of operation, check and

clean the cooling fins and inside the engine

shrouds to remove grass, chaff or dirt

clogging the cooling system and causing

overheating.

WARNING: Hot engine

components can cause severe

burns. Stop engine and allow it

to cool before checking the

spark plug.

Figure 25

OE3336

Hose Clamps

Fuel Filter

Figure 26

Spark Plug Wire

OE3341

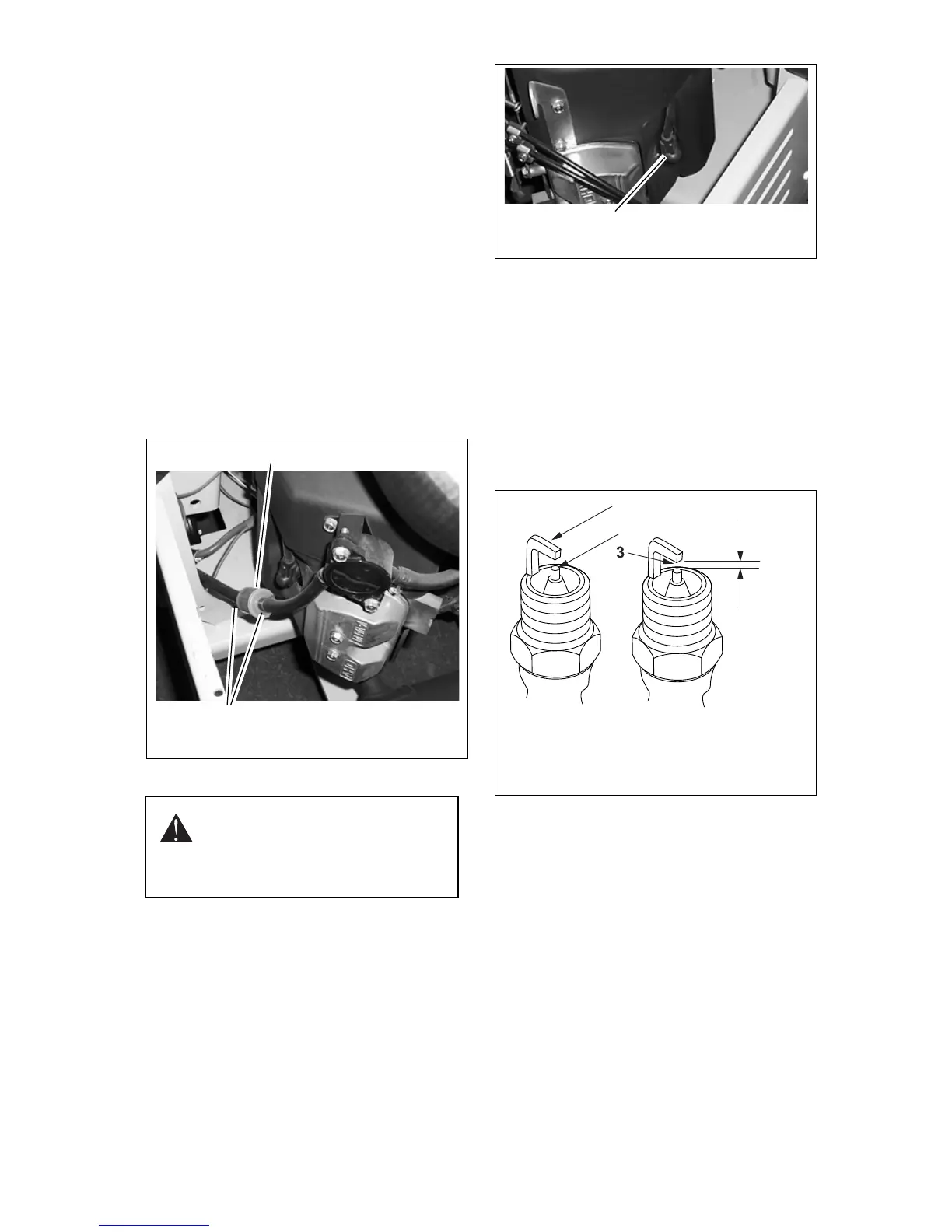

Figure 27

.030 in.

(.75mm)

1. Center Electrode Insulator

2. Side Electrode

3. Air Gap (Not to Scale)

Loading...

Loading...