FULL-WAVE

RECTIFIER

EXPERIENCE

DISCUSSION

The

process

of changing alternating current

(AC)

to direct

current

(DC)

is

called rectification.

A full-wave rectifier uses

both halves of the AC cycle in the rectification

process. That

is, it

produces

one

DC

voltage

pulse

for

each

one-half cycle

of

AC,

as

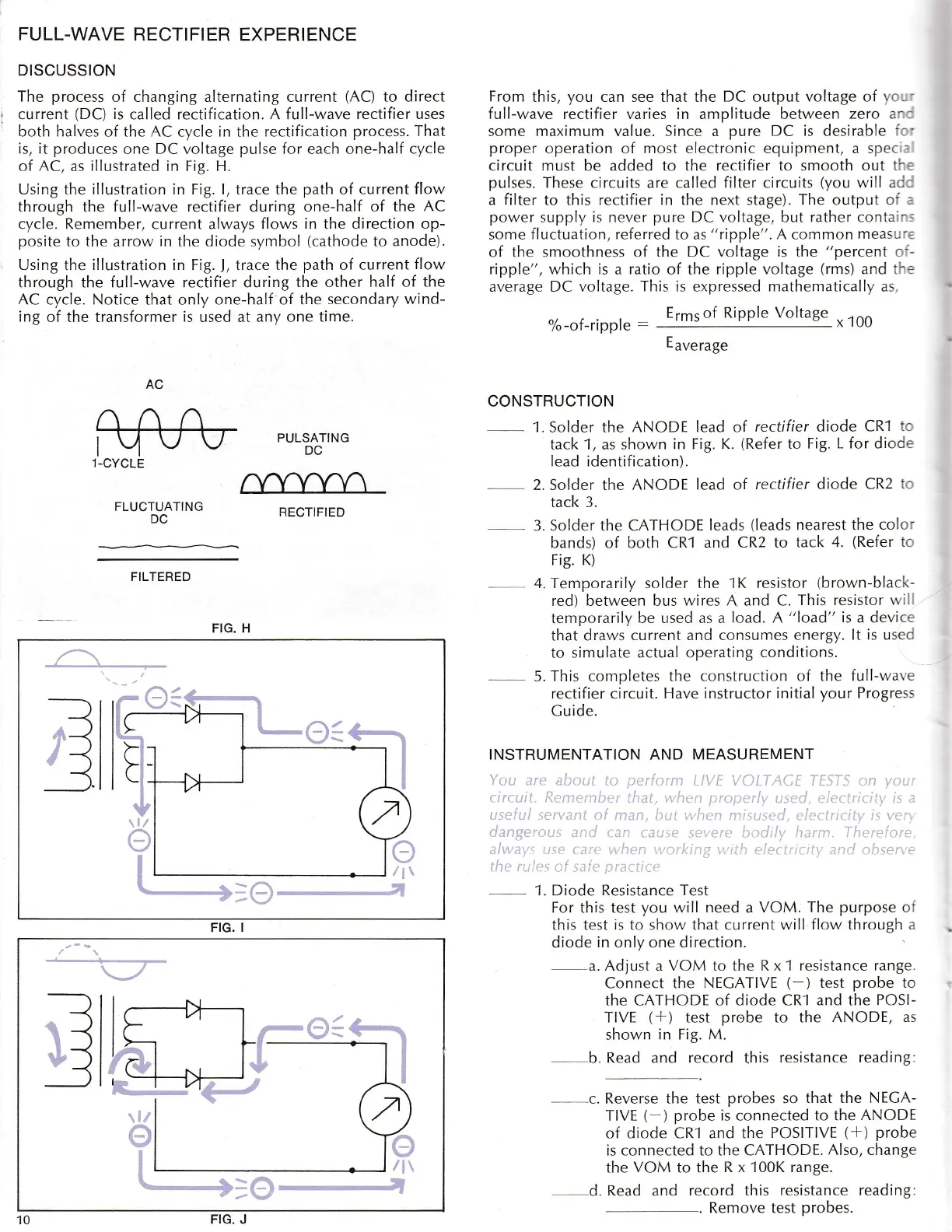

illustrated in Fig. H.

Using the

illustration in

Fig. l, trace the

path

of

current flow

through the full-wave rectifier during one-half

of the AC

cycle. Remember,

current always

flows in the direction op-

posite

to the arrow in the diode symbol

(cathode

to

anode)

.

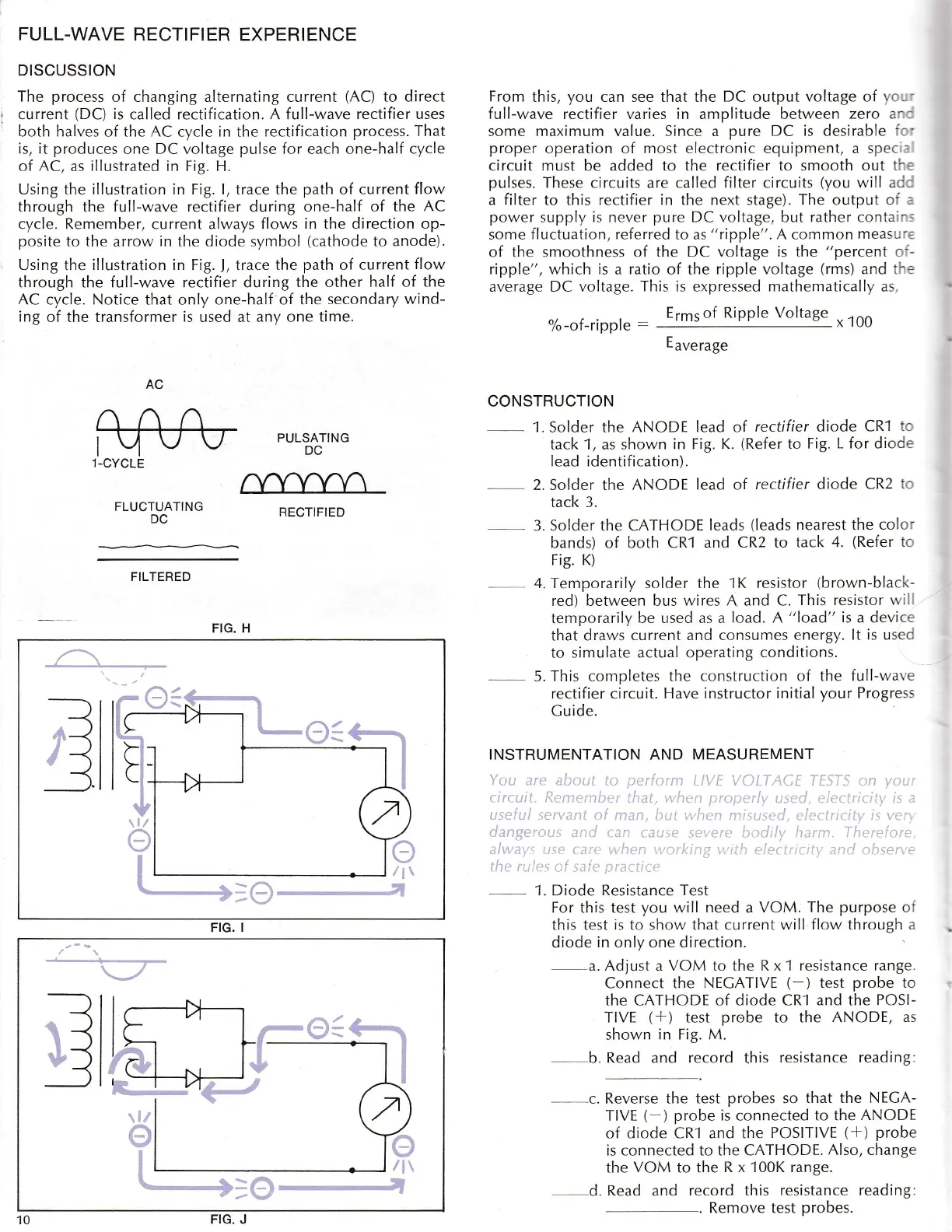

Using the illustration in Fig.

l,

trace the

path

of

current

flow

through

the full-wave

rectifier

during

the other

half o{ the

AC

cycle. Notice that only one-half of

the secondary

wind-

ing

of the transformer

is

used at any

one time.

From

this,

you

can see that the

DC

output

voltage of

r', .'

full-wave

rectifier varies

in

amplitude between

zero ?'

some

maximum

value. Since a

pure DC is desirab!e

'

'

proper

operation of most electronic equipment, a spe.

circuit must be added to the rectifier to smooth out

t-.

pulses.

These circuits are called

filter

circuits

(you

will a,:

-

a

filter

to this rectifier

in

the next stage)

. The

output

o:.

power

supplv

is never

pure

DC voltage, but rather conta'-.

some

fluctuation, referred

to as

"ripple".

A common

measL.

-.

of the smoothness

of the DC voltage

is

the

"percent.'-

ripple", w.hich is a ratio

of the

ripple voltage

(rms)

and i:-

average DC

voltage. This is

expressed

mathematicall',, 25

%-of-ripple

_

Ermsof Ripple Voltage

*

100

E

average

CONSTRUCTION

-

1.

Solder

the ANODE lead of

rectifier diode

CR1

i:

tack 1, as shown

in Fig. K.

(Refer

to

Fig. L for dioc=

lead identification).

2. Solder the

ANODE lead of

rectifier diode CR2

:

tack 3.

-

-

3. Solder the CATHODE

leads

(leads

nearest

the colc:

bands) of both CR'l

and CR2 to

tack 4.

(Refer

tr,

Fig. K)

-

4. Temporarily solder the

1K resistor

(brown-black-

red) between bus

wires A and C.

This resistor

lr'r

temporarily be used as a

load. A "load"

is

a devict

that draws

current and consumes

energy. lt

is

usec,

to simulate actual

operating conditions.

5. This completes the

construction of the

full-wate

rectifier

circuit. Have

instructor initial

your

Progress

Cuide.

INSTRUMENTATION AND MEASUREMENT

-

-

1. Diode Resistance Test

For this test

you

will need

a

VOM.

The

purpose

c'

this test

is

to show,that current

will flow through

a

diode

in

only

one direction.

a. Adjust a VOM to the R x

1 resistance range.

Connect the NECATIVE

(-)

test

probe

to

the CATHODE of diode CR1

and the

POSI-

TIVE

(+)

test

probe

to the

ANODE, as

shown

in

Fig. M.

b. Read and

record

this

resistance

reading:

-

c.

Reverse the test

probes

so that the NECA-

TIVE

(

)

probe

is connected to the

ANODE

of

diode

CR1 and the

POSITIVE

(l)

probe

is connected to the CATHODE.

Also, change

the

VOM

to the

R x 100K range.

M\N.,

PULSATNG

1-CYCLE

FLUCTUATING

DC

nrrnn^

RECTIFIED

FILTERED

=l

jli

FIG.

d.

Read and record this

Remove

resistance reading

test

probes.

?

E

10

FIG. J

\-/

o<

lt

FIG. H

;o

Loading...

Loading...