GMV5 DC INVERTER VRF UNITS SERVICE MANUAL

58

The minimum distance between supports, hangers, and brackets is listed in the table below:

External Diameter of the

Pipe (mm)

Distance between

Horizontal Pipes (mm)

Distance between Vertical

Pipes (mm)

The pipe led through a wall or beam must be fixed by a support, hanger, or bracket on both ends at

the position 300 mm away from the hole.

3.4 Pipe Connection

3.4.1 Flaring Connection

The refrigerant pipes and IDUs are connected by using the flare opening. Therefore, the quality of

flaring connection must be ensured. The flaring depth of the bell mouth cannot be smaller than the

caliber. The flaring direction must face towards the direction of medium flow. Use two torque wrenches to

fasten the connection.

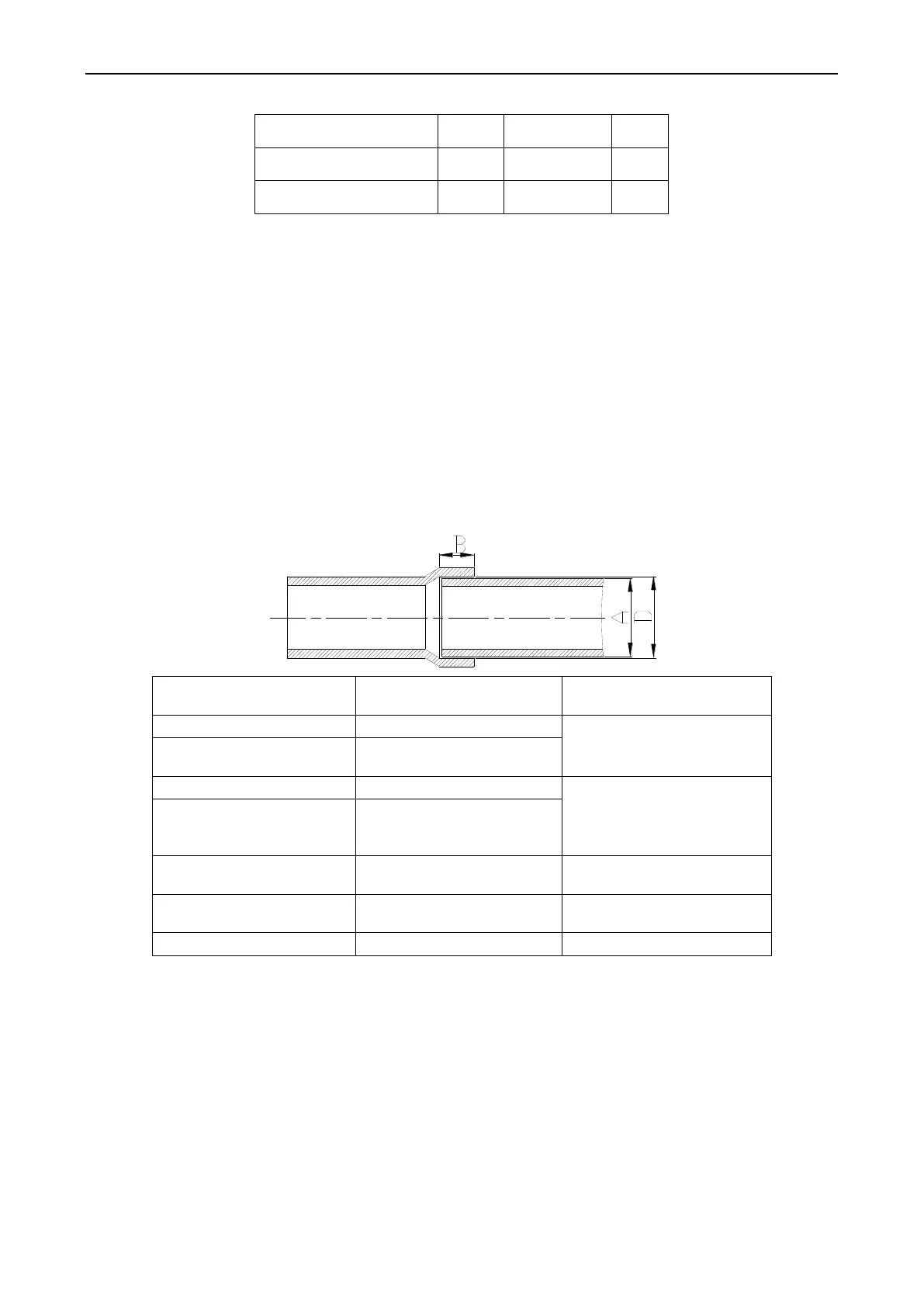

3.4.2 Socket Welding

The gap between socket components should be proper to ensure that the connection will not loose

from the friction surface. The flaring direction of the socket component must face towards the direction of

medium flow .During pipe connect, protect the braze welding part according the length specified below:

A: External Diameter of

the Pipe (mm)

B: Minimum Insertion

Depth (mm)

D-A: Gap between Pipes

(mm)

3.4.2 Bell Socket Welding

The bell socket welding is another form of socket welding. It uses the sleeve or pipe in a larger size

for welding. The insertion depth cannot be smaller than that required by socket welding.

3.4.5 Flange Connection

The pipes with large caliber and the devices are always connected by using a flange, which must be

clean and intact. Before installation, apply lubricant on the surface of the flange. Two flanges must be

symmetrical. Fasten with screws at the diagonal direction to avoid inclination.

3.5 Welding Protection

Aerate with nitrogen before and during welding and keep aerating for 30 s after the welding is

finished.

Loading...

Loading...