D.C. Inverter Multi VRF Modular

27

(2) Weld the connection pipes between indoor and outdoor unit. Please strictly conform to the

requirements for welding process. Rosin joints and pin holes are not allowable.

(3) When laying the pipes, be careful not to deform them. The radius of bending parts should

be more than 200mm. The pipes can not be repeatedly bent or stretched, otherwise the

material will get harden. Do not bend or stretch the pipe over three times at the same

position.

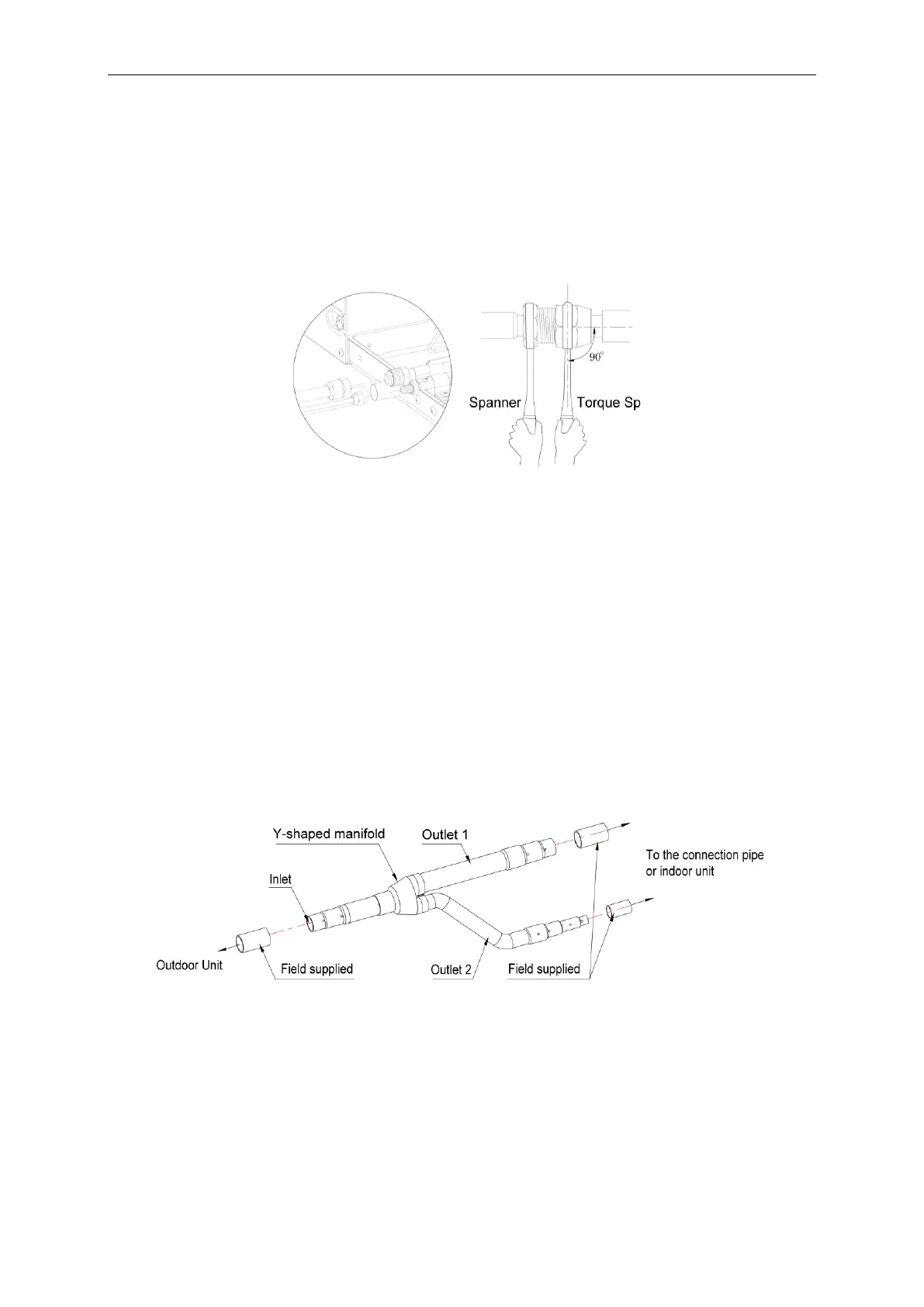

(4) Please use a torque wrench to connect union nut on the indoor unit.See Fig. 29.

Fig.31

1) Align the expansion end of copper pipe with the center of threaded joint. Tighten the

flare nuts with your hands.

2) Tighten the flare nuts with torque wrench until you hear "click" sound.

3) Use sponge to wrap the connecting pipe and joints without thermal insulation and tie it

up with plastic tape.

4) A mounting support for the connection pipe is required.

5) The curvature degree of connection pipe should not be small, otherwise the pipe might

crack. Installation personnel should use tube bender when bending the pipe.

6) Don't forbibly stretch the pipe joint, otherwise indoor capillary or other pipes might be

damaged and lead to refrigerant leakage.

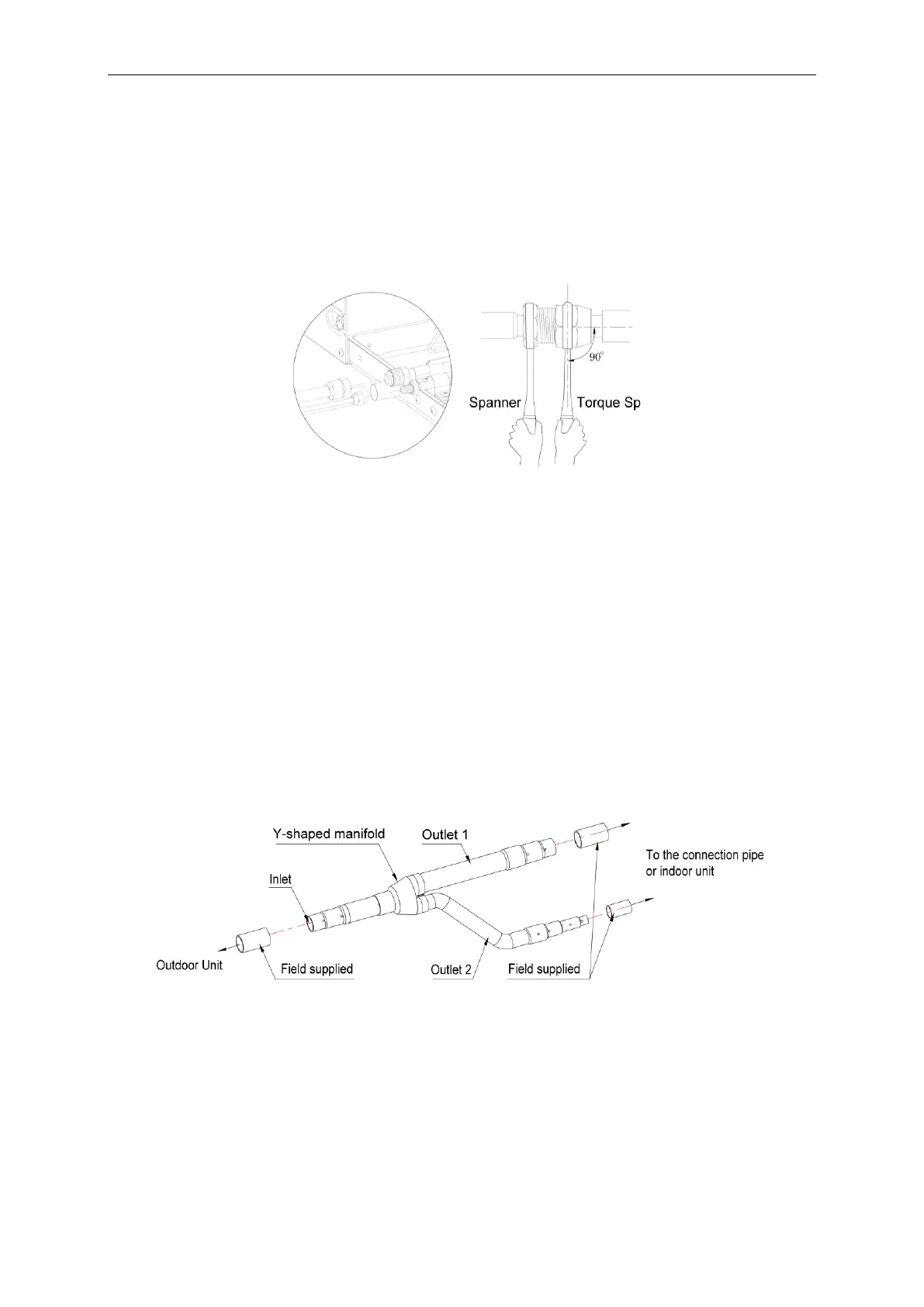

4.3.2 Y-type manifold

(1) Y-type manifold

Fig.32

(2) Y-type manifold has serveral pipe sections with different pipe size, which facilitates to

match with various copper pipe. Use pipe cutter to cut in the middle of the pipe section

with different pipe size and deburr as well. See Fig.31.

(3) Y-type manifold must be installed vertically or horizontally.

Loading...

Loading...