Upblast Centrifugal Roof Exhaust 9

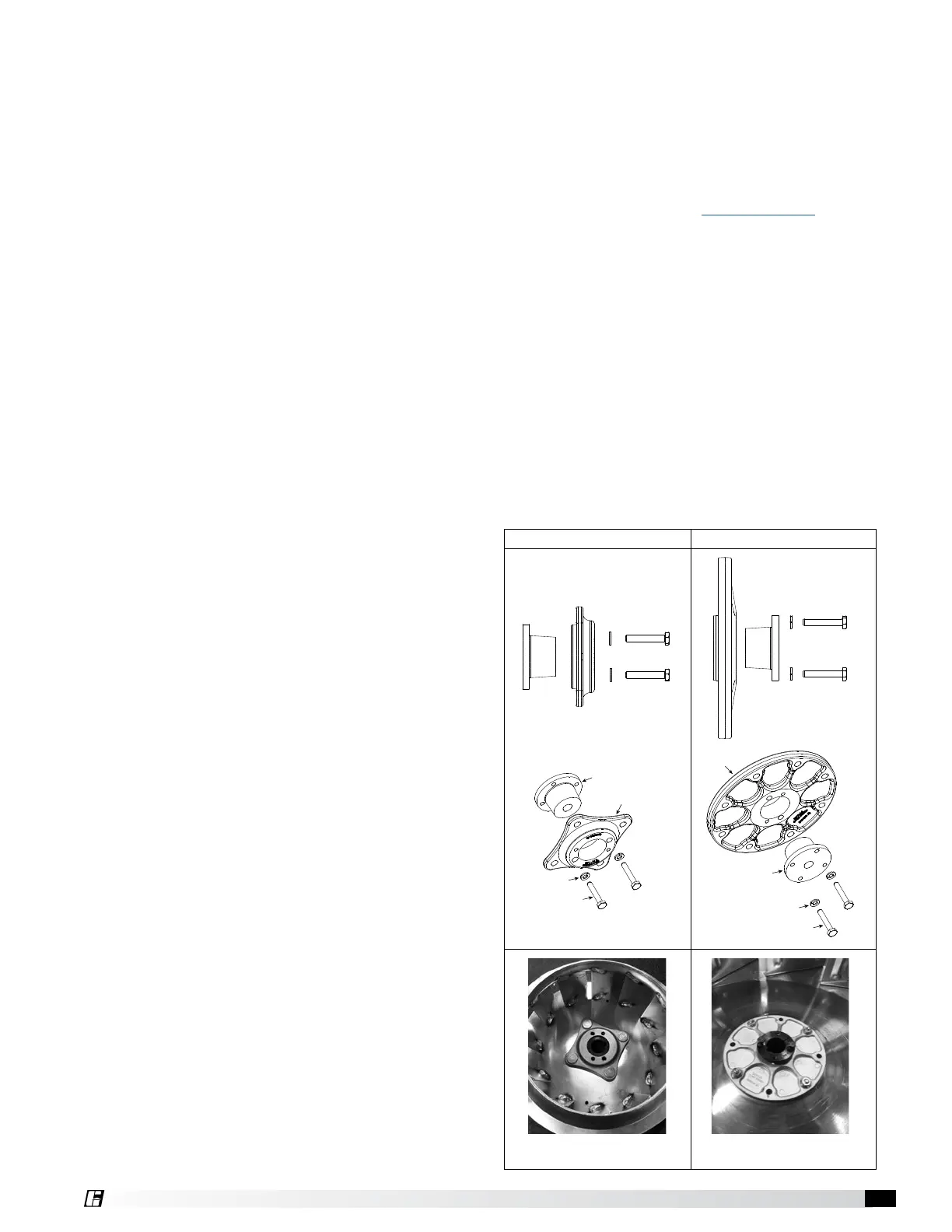

Tapered Bushing Hub Installation

and Removal

For wheel hubs and shaft pulleys utilizing a tapered

bushing interface, follow this procedure for installation

and removal. There are two possible set ups for the

tapered bushing, both have the same procedure, but

orientation of the hub varies.

Tapered Bushing Removal (click for video):

1. If present, loosen the setscrew holding the bushing

and shaft key in place.

2. Loosen and remove the socket head cap screws

which fasten the bushing to the hub as shown in the

section views and examples of Figures 19-22.

3. Standard Mounting: Take the two socket head cap

screws that were removed and install them into the

visibly threaded holes on the wheel hub.

Reverse Mounting: Install the two socket head cap

screws into the visibly threaded holes of the bushing

flange.

4. Once both socket head cap screws are installed,

tighten them an eighth of a turn at a time, alternating

between the two until the hub comes loose from the

bushing.

Standard Mounting Reverse Mounting

Figure 19 Figure 20

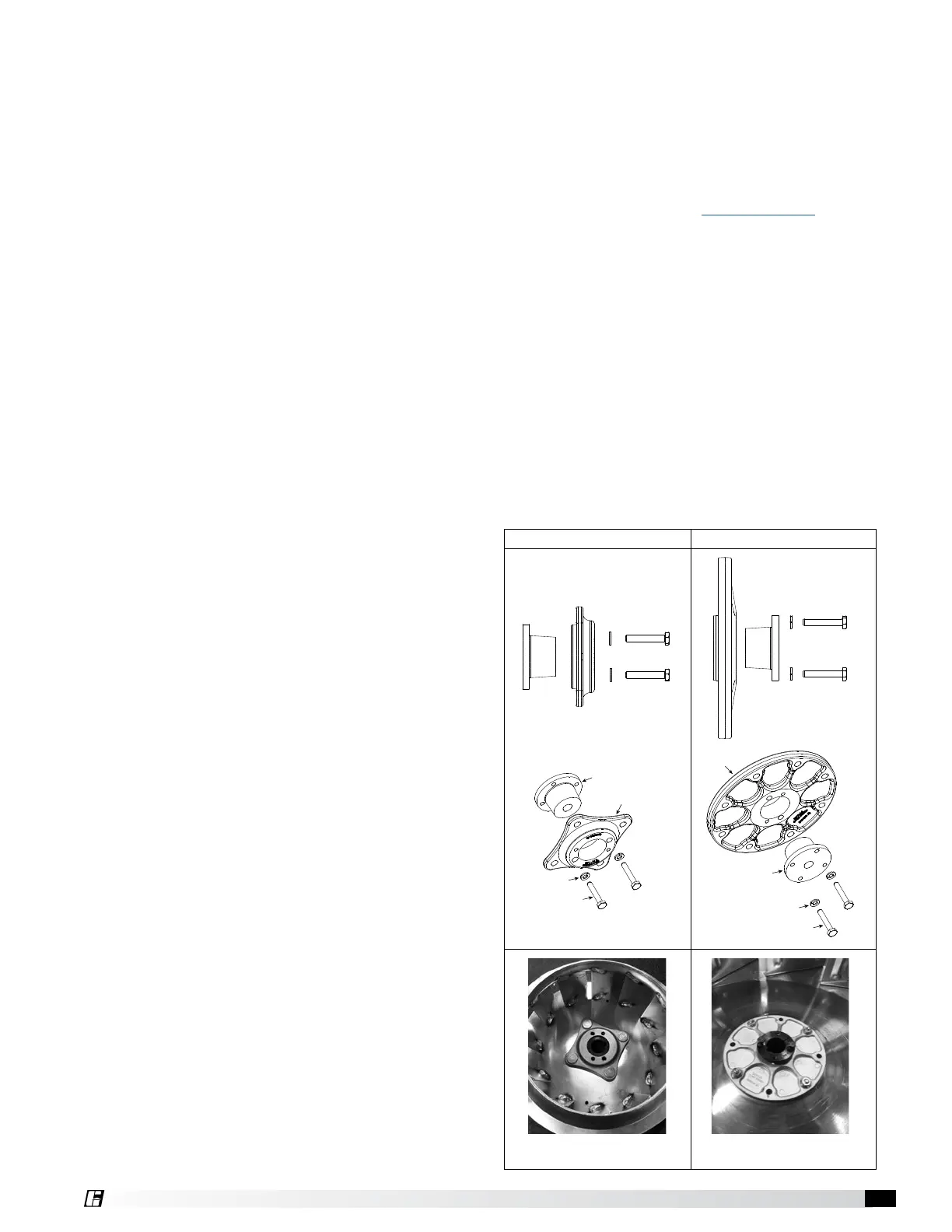

Figure 21

Standard Bushing Orientation

Figure 22

Reverse Bushing Orientation

Bushing

Washers

Cap Screws

Hub

Bushing

Washers

Cap Screws

Hub

Bushing

Washers

Cap Screws

Hub

Bushing

Washers

Cap Screws

Hub

Powerpack Replacement

1. Ensure power is turned off to the fan.

2. Remove hood to gain access to motor compartment

by pushing in two adjacent snap buttons and lifting.

3. Disconnect motor wiring and controls wiring (if

present).

4. Remove the 4 or 6 screws which secure the

powerpack in place.

5. Carefully lift out the powerpack while keeping the

powerpack assembly centered to the housing so the

wheel doesn’t catch on the hoodband.

6. Set down the powerpack somewhere that won’t be

damaged by the metal components.

7. Pick up new powerpack and place into housing in

the same orientation as the previous one.

a. Be mindful of the conduit tube(s) coming

through the hoodband, they should align with

rounded clearance features in the powerpack.

8. If possible, spin the wheel by hand to check for

wheel rub. If rubbing occurs, adjust powerpack

accordingly until it stops.

9. Re-install the screws removed in step 4.

10. Reconnect any wiring that was disconnected in step

1 and restore power.

11. Turn on power to the fan. If no issues are detected,

re-install the hood.

Installation and maintenance are to be performed only

by qualified personnel who are familiar with local codes

and regulations and who are experienced with this type

of equipment.

Motor maintenance is generally limited to cleaning

and lubrication (where applicable). Cleaning should be

limited to exterior surfaces only. Removing dust buildup

on motor housing ensures proper motor cooling.

Greasing of motors is only intended when fittings are

provided. Many fractional horsepower motors are

permanently lubricated and should not be lubricated

after installation. Motors supplied with grease fittings

should be greased in accordance with manufacturer’s

recommendations. Where motor temperatures do not

exceed 104ºF (40ºC), the grease should be replaced

after 2,000 hours of running time as a general rule.

Wheels require very little attention when moving clean

air. Occasionally, oil and dust may accumulate causing

imbalance. When this occurs, the wheel and housing

should be cleaned to ensure smooth and safe operation.

All fasteners should be checked for tightness each time

maintenance checks are performed prior to restarting

unit.

• When installing fans for restaurant exhaust

applications follow NFPA 96 for cleaning fans.

• Grease containers must be emptied at regular

intervals to prevent overflow.

A proper maintenance program will help these units

deliver years of dependable service.

Loading...

Loading...