General Description - NOT model specificEnergy Recovery Ventilator with Heating and Cooling

32

Belt Drive Installation

1. Remove the protective coating from the

end of the fan shaft and assure that it is

free of nicks and burrs.

2. Check fan and motor shafts for parallel

and angular alignment.

3. Slide sheaves on shafts. Do not drive

sheaves on as this may result in bearing

damage.

4. Align fan and motor sheaves with a

straightedge to centerline.

5. Place belts over sheaves. Do not pry

or force belts, as this could result in

damage to the cords in the belts.

6. With the fan off, adjust the belt tension

by moving the motor base. (See belt

tensioning procedures in the Routine

Maintenance section of this manual).

When in operation, the tight side of the belts should

be in a straight line from sheave to sheave with a

slight bow on the slack side.

Belt Span

Deflection =

Belt Span

64

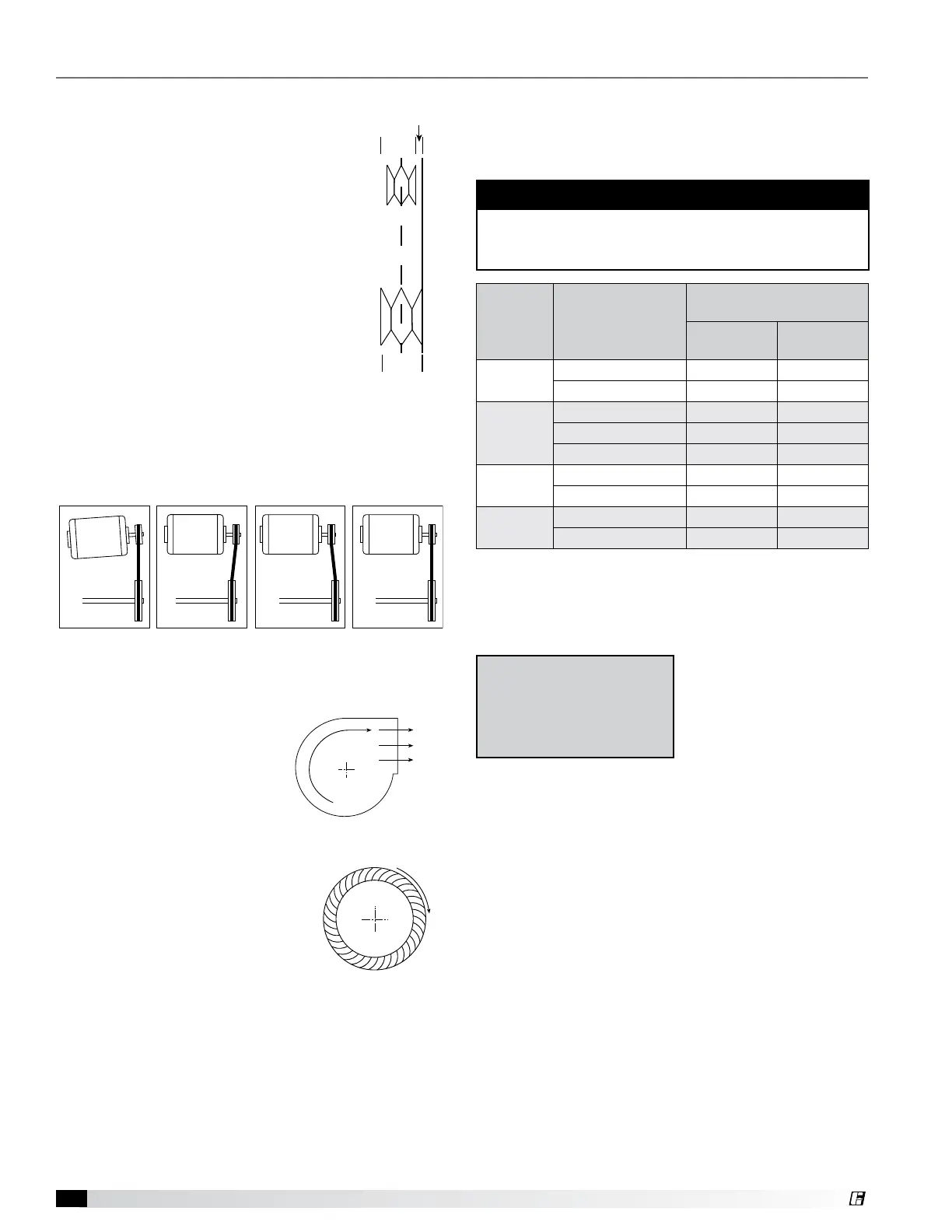

WRONG WRONG

WRONG CORRECT

WRONG WRONG

WRONG CORRECT

Proper alignment of motor and drive shaft.

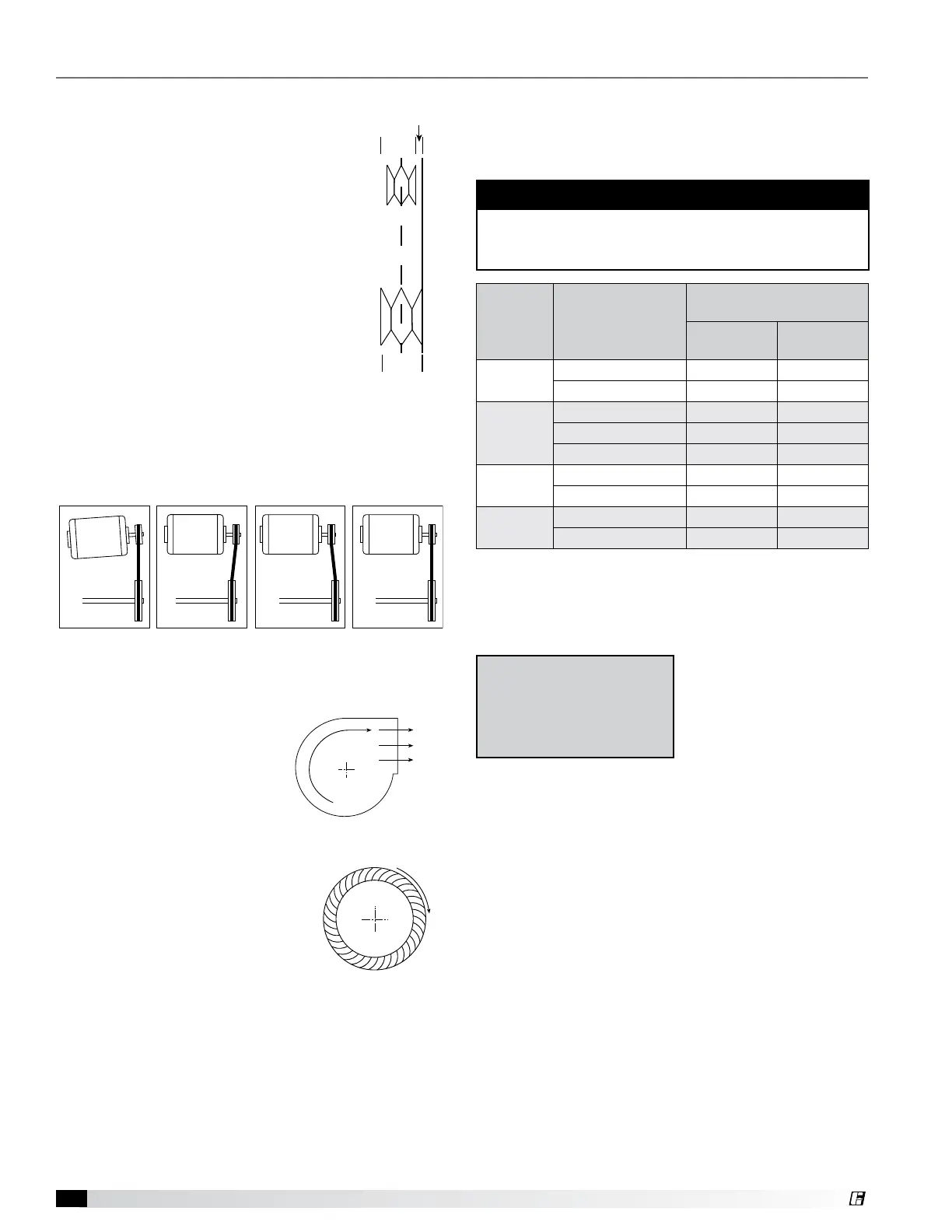

Direction of Fan Wheel Rotation

Blower access is labeled on unit.

Check for proper wheel rotation

by momentarily energizing the

fan. Rotation is determined

by viewing the wheel from the

drive side and should match the

rotation decal affixed to the fan

housing.

If the wheel is rotating the wrong

way, direction can be reversed

by interchanging any two of the

three electrical leads.

Check

for unusual noise, vibration, or

overheating of bearings. Refer to

the Troubleshooting section of this

manual if a problem develops.

Fan RPM

Supply fan and exhaust fan will have an adjustable

motor pulley (on 15 HP and below) preset at the factory

to the customer-specified RPM. Fan speed can be

increased or decreased by adjusting the pitch diameter

of the motor pulley. Multi-groove variable pitch pulleys

must be adjusted an equal number of turns open

or closed. Any increase in fan speed represents a

substantial increase in load on the motor. Always check

the motor amperage reading and compare it to the

amperage rating shown on the motor nameplate when

changing fan RPM. All access doors must be installed

except the control center door.

WARNING

Do not operate units with access doors open or

without proper ductwork in place as the fan motors

will overload.

Model

Blower Diameter

x Width

(inches)

Maximum RPM for

Forward-Curved Blowers

Class I

Max RPM

Class II

Max RPM

ERCH-20

10 x 6 1700 --

9 x 9 1750 2800

ERCH-45

9 x 9 1750 2800

12 x 8 1400 2000

12 x 12 1500 2000

ERCH-55

12 x 12 1500 2000

15 x 15 1250 1725

ERCH-90

15 x 15 1250 1725

18 x 18 1000 1450

Vibration

Excessive vibration may be experienced during initial

start-up and can cause a multitude of problems,

including structural and/or component failure.

Many of these conditions

can be discovered by

careful observation. Refer

to the Troubleshooting

section of this manual

for corrective actions.

If observation cannot locate the source of vibration, a

qualified technician using vibration analysis equipment

should be consulted. If the problem is wheel unbalance,

in-place balancing can be done.

Generally, fan vibration and noise is transmitted to other

parts of the building by the ductwork. To eliminate this

undesirable effect, the use of heavy canvas connectors

is recommended.

Hot Gas Bypass Valve (standard scroll)

To adjust, connect a pressure gauge to the suction line

and block the entering air to the evaporator coil. The

valve should begin to open when the suction pressure

drops to approximately 115 PSIG for R-410A (the valve

will feel warm to the touch). Adjustments are made by

first removing the cap on the bottom of the valve and

then turning the adjusting stem clockwise to increase

the setting pressure (counterclockwise to decrease).

Allow several minutes between adjustments for the

system to stabilize. When adjustment is complete,

replace the cap on the valve.

2 in.

1.5 in.

0.25 in.

centerline

straightedge

Pulley

alignment

example

Vibration Causes

Off axis or loose components

Drive component unbalance

Poor inlet / outlet conditions

Foundation stiffness

Backward Inclined

Forward Curved

Airflow

Airflow

Backward Inclined

(ERT)

Forward Curved

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Backward Inclined

Forward Curved

Airflow

Airflow

Backward Inclined

(ERT)

Forward Curved

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Start-Up Components

Loading...

Loading...