8

VGN Technology

®

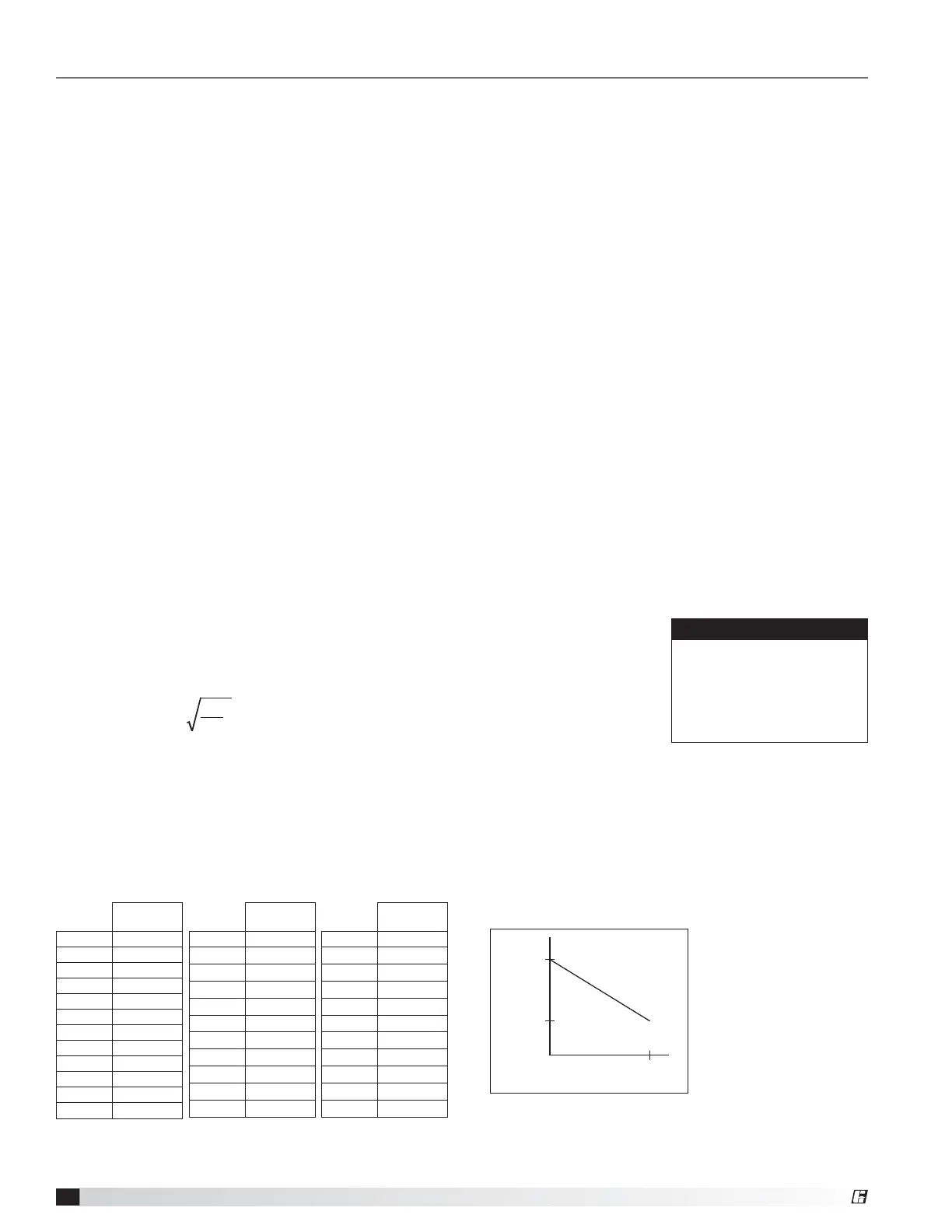

VELOCITY

VDC

0 10

3000

2000

DC Voltage to

Velocity Relationship

Sending 0 VDC to the B5 input on single fan or U5 input

on multifan of the Carel controller will default the nozzle

velocity to the maximum outlet velocity set by the user.

Sending 10 VDC to the B5 input on single fan or U5

input on multifan of the Carel will adjust the nozzle

velocity to the minimum outlet velocity set by the user.

Sending a DC voltage between 0 and 10 VDC will adjust

the nozzle outlet velocity linearly.

BMS Communication Programming

The VGN controller uses analog and digital

communications that are hard wired to the BMS to

communicate with the BMS.

Fan Run Signal can be switched by the BMS or VFD.

The VGN controller requires a 24 VAC fan run input

signal from BMS or VFD to communicate to the VGN

controller that the fan is running. Use a switching relay

contact controlled by the VFD or BMS to control the fan

run signal; the contact should be closed when the fan is

running. Multiple fan systems will require a separate fan

run signal for each fan which corresponds to each fan

number.

Nozzle Feedback will report the position of the

nozzle during operation. It is necessary to maintain

the minimum required nozzle outlet velocity. Each

nozzle has two feedback outputs, one for each blade

of the nozzle. The output from the nozzle feedback is a

2-10VDC voltage. To properly maintain required nozzle

outlet velocity the minimum allowable nozzle feedback

voltage is 2.1 VDC. If the nozzle feedback drops

below this voltage the fan speed must be increased to

maintain the required nozzle outlet velocity. Modulation

of the bypass damper may be required to maintain

proper duct pressure while maintaining required nozzle

outlet velocity.

Fan Flow This feature is not required for system

operation; this feature allows the BMS to record and

display the CFM of the fan during operation. Each fan

has one 0-10 VDC output for fan flow.

To calculate the fan flow and display it on the BMS use

the following calculations:

CFM = K-Factor •

ΔP

J

a. ΔP is calculated with the following equation:

((SURAIR Voltage)/10))*15

b.

J

is air density which is job site specific; a universal

number to use is .075 lbm/ft

3

c. K-Factor is listed on a data plate located on the fan

body or refer to the charts below; each fan type and

size have a unique K-Factor number.

NOTE: Repeat steps above for fan 2, 3, and 4 if

applicable.

Vektor-MS

(VK-M-XX)

Fan Size K-Value

15 526

18 787

20 955

22 1161

24 1436

27 1729

30 2116

33 2581

36 3154

40 3825

Vektor-HS

(VK-H-XX)

Fan Size K-Value

9 248

10 202

12 296

13 351

16 440

18 542

22 804

24 971

30 1463

36 2167

Vektor-CS

(VK-C-XX)

Fan Size K-Value

12 296

15 431

18 542

22 805

24 982

27 1184

30 1464

33 1770

36 2168

40 2630

44 3220

Alarm The alarm will notify the BMS of issues with

the VGN control system by closing a dry relay contact

within the Carel controller. There is only one alarm

contact for the entire VGN control system regardless of

the number of fans. The Carel controller located in the

VGN control box will display the alarm history to help

diagnose the issue; no alarm history will be transmitted

to the BMS.

The alarm contact will close due to the following issues:

The fan run signal shows the fan running but the

0-10VDC signal from the pressure transducer is not

within the expected range. This could be due to wiring

issues, failed pressure transducer, closed isolation

damper, water in the pressure transducer tubes, or the

fan motor is not spinning.

Outlet Velocity: On the Fly Unoccupied

Adjustment

This feature is not required for system

operation. This feature allows the user to adjust the

nozzle outlet velocity remotely while the fan is running

with the use of a 0-10 VDC signal sent from the BMS

to the VGN controller. This feature is used to reduce

energy costs during unoccupied or low use lab times.

It can also be used with real time wind wake study

data to optimize energy consumption. Lower nozzle

velocity will equate to lower plume height and lower

system restriction; it is the responsibility of the user to

determine what nozzle velocity is required.

In the “User Settings”

menu of the Carel menu,

the user can set the

nozzle outlet velocity

maximum and minimum

settings.

USER SETTINGS

ELEVATION: 0 FT

MAX OUT VEL: 3000 FPM

MIN OUT VEL: 2000 FPM

ACTIVE STPT: 3000 FPM

FOR TEST/BALANCE

PRESS DOWN ARROW

Loading...

Loading...