Greenlee / A Textron Company 22 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

980 Hydraulic Power Pump

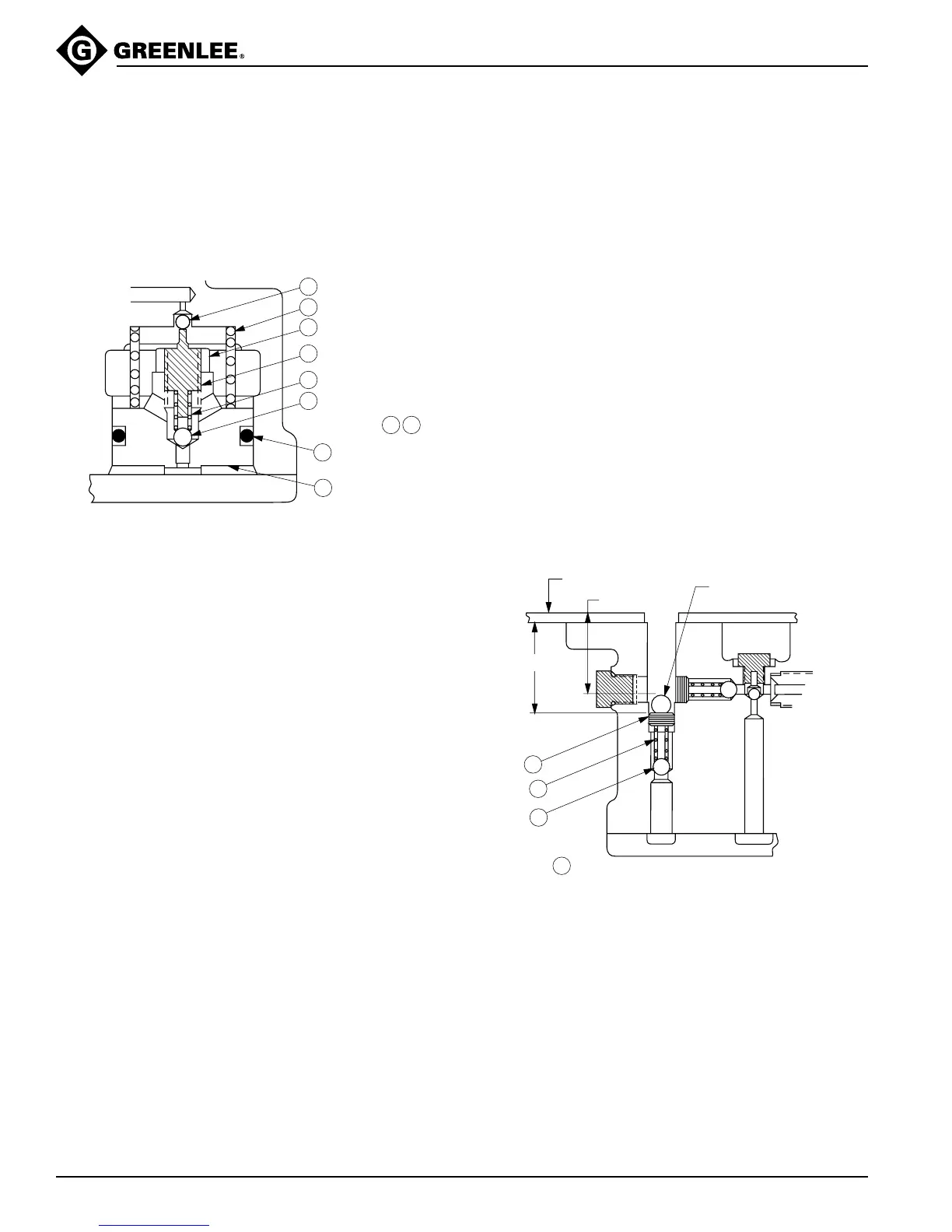

Low-Pressure Bypass Check Pressure Adjustment

When properly set to the dimension shown in Figure A5,

the high pressure stage operation of the pump will be

delayed approximately one (1) second after the motor

starts. This delay is created by the closing time of the

pilot-operated valve.

Note: This dimension must be increased if ball seat

depth is increased by more than 0.4 mm (1/64 inch).

Increasing the bypass pressure (CW rotation of adjusting

screw—increase of set dimension) will shorten delay. If

delay becomes too short, the motor will not restart when

high pressure is held in the line. The motor should restart

with a maximum required off time of 1/2 to 1 second.

Decreasing the bypass pressure (CCW rotation of

adjusting screw) will increase delay. The pilot-operated

valve will not close if pressure is set too low.

Changes in oil temperature (viscosity) will affect the

amount of delay. The pumping delay will increase with

rising oil temperature (thinner oil).

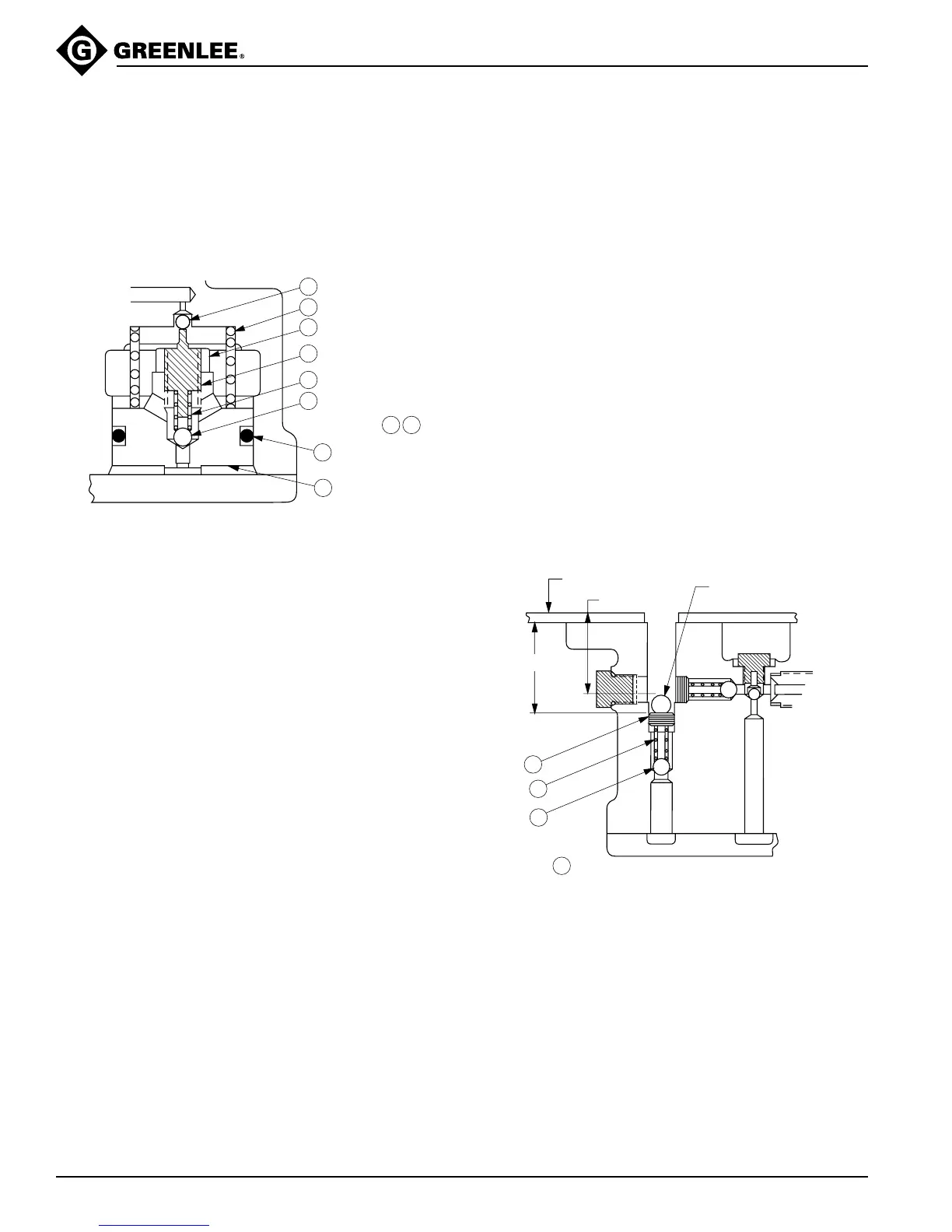

Low Pressure Relief Setting

Refer to Figure A4. Lightly bottom the stem (44) on the

ball (46). Then, back out the stem 3-1/2 turns. Tighten

nut (43). The resulting pressure setting should be

approximately 19 bar (280 psi).

Repairs (cont’d)

44

3

Figure A4

7

42

47

43

45

46

49

48

COVERPLATE

36.17 mm (1.424")

8 mm (5/16") Ø BALL

(used to make measurement)

37.29 mm (1.468")

69

70

71

4

Figure A5

Loading...

Loading...