Operation manual SP 9 - Compact

CHAPTER VII – P

REPARATION OF PLOUGH BEFORE THE OPERATION – Page 4

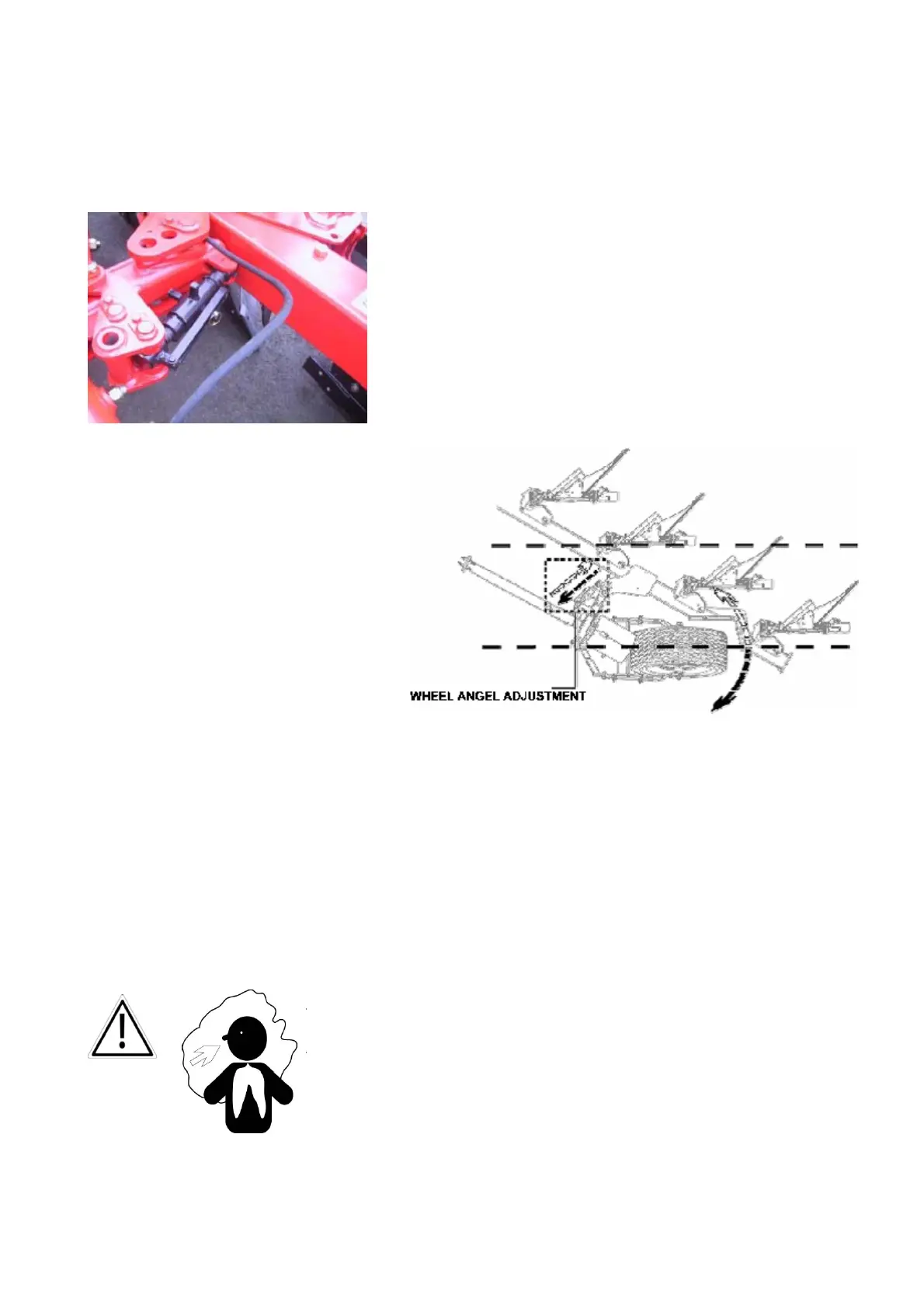

7.4. THE WHEEL ANGLE ADJUSTMENT

The wheel direction adjustment can be performed by the mechanic adjusting arm, which can

be displaced optionally by the hydraulic cylinder. With this adjustment the plough tractive line

can be controlled.

If the working width is changed the wheel angle should be

corrected a

s well. With the help of the adjusting lever put

in the same line the wheel axle and the connecting axle.

The wheel axle should be perfectly put

in paralell with the plough sole, it can be

seen on the figure. When the mechanic

controlling lever or cylinder pulls back,

the wheel approaches the beam. And

vice vise when the mechanic lever or

cylinder is pushed the wheel moves off

the beam.

7.5. PREPARATION OF THE NEW PLOUGH

BEFORE THE OPERATION

The Grégoire-Besson ploughs are protected against rust before they leave the plant. They are not

able to perform correct operation till the protective plaint is abraded because of the chafing to the

ground.

The black paint (or clear lacquer) will be chafed in some hectares. But if there is soil which does

not have any chafing affect (peat, clay, sludge), it would be better if you rub off the paint before

starting to plough. It may happen that ground adhere to the breast and it does not slide. For this

purpose apply paint stripper. If it is necessary use stronger material for taking of the paint.

ATTENTI

ON : During the work pay attention to the proper airing if

you apply paint stripper to the breast. Wear goggles and protective

gloves. Pay attention to the direction of the wind.

NB : On the first day to operate the plough easier helps the dismounting of the chisel nose which can

make penetration into the soil quickly especially to the heavy soil.

Loading...

Loading...