Translation of the original instructions

TINE SHAFT

Remove the dust guards periodically (fib. 5 no. 11), clean the underlying area thoroughly, then replace.

The observance of these rules helps to keep all the mechanical parts of your machine fully

efficient.

TIPS FOR EFFICIENT USE

1) Always raise the clutch red lever (fig. 1, no. 2) before shifting from forward to reverse gear.

2) Never leave the machine exposed to bad weather condition.

3) Always keep levers and cables well clean from dust and ground residues.

4) Never force the gear: If the gear does not engage immediately, give light touches on the clutch until it

engages.

5) Never strain the engine: if smoke comes out of the exhaust, slow down.

END OF SEASON MAINTENANCE

Thoroughly clean the machine, replace both the engine and the gearbox oil, clean the air filter, sharpen

and grease the tines and replace them if worn. IMPORTANT: Grillo tines are made of a special steel

subjected to heat treatments. Never weld the tines if broken or cracked, because they could

break and be flung away becoming therefore highly dangerous for people and objects around.

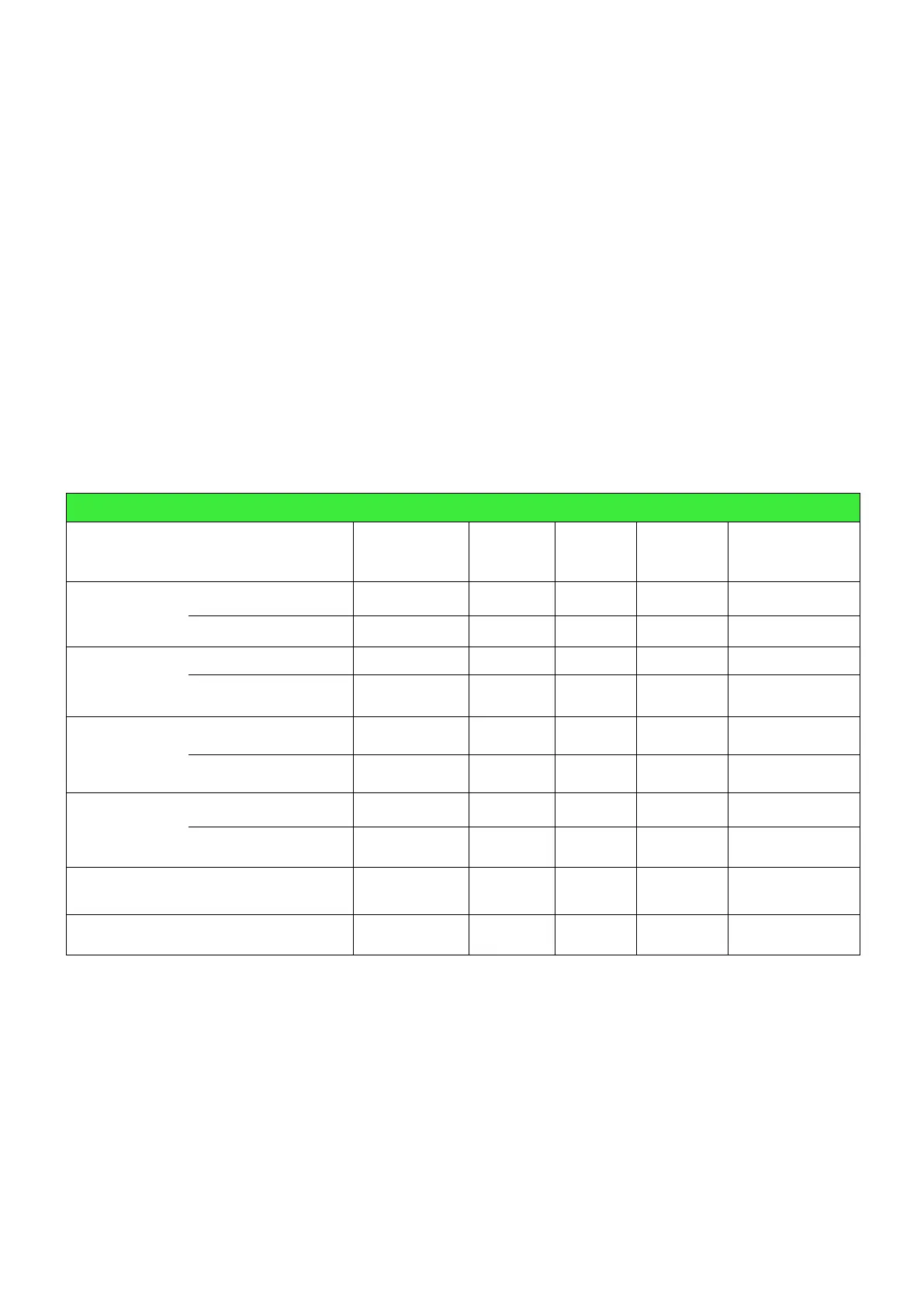

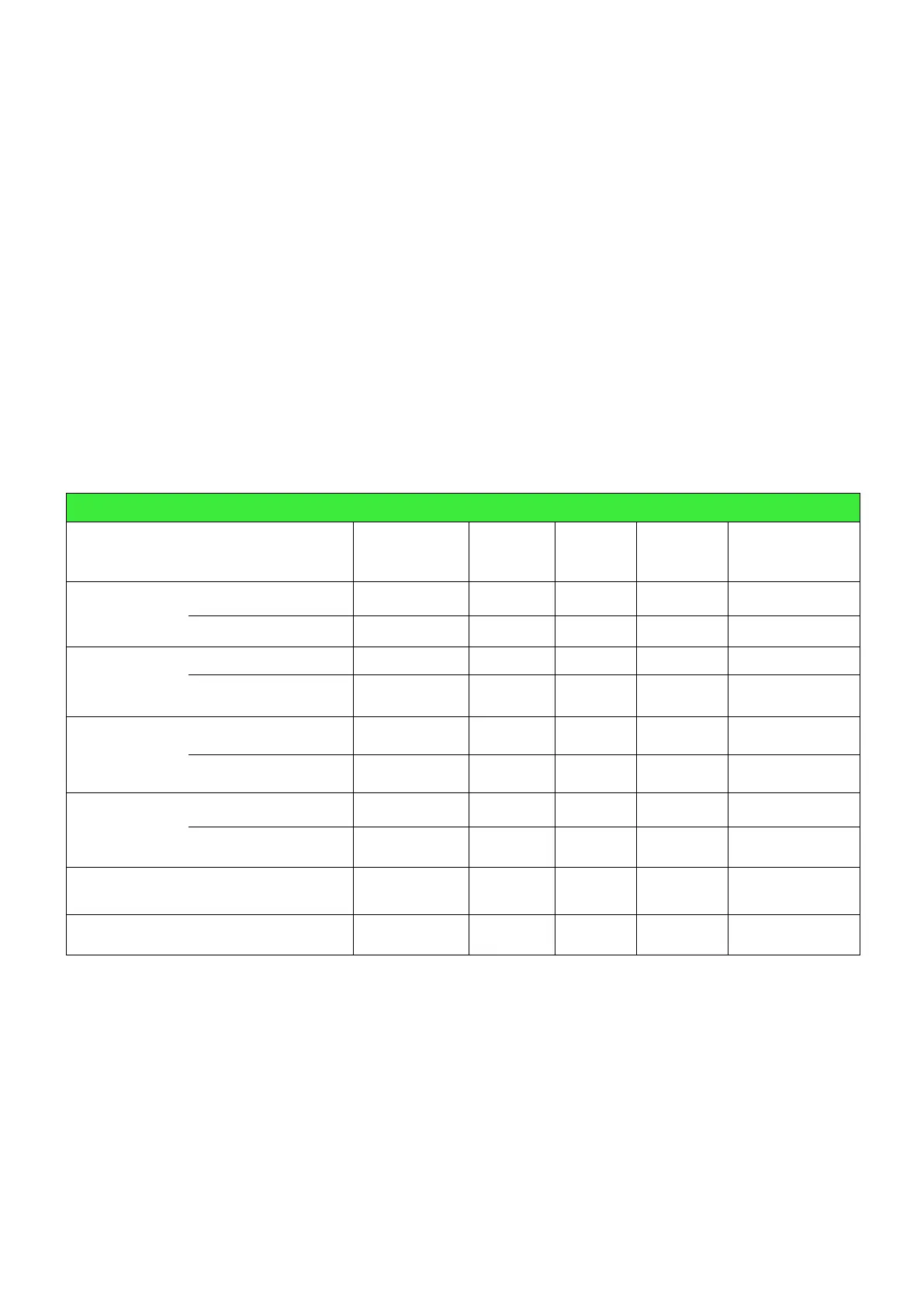

MAINTENANCE SUMMARY TABLE

PROCEDURE EVERY 8

HOURS

AFTER 20

HOURS

EVERY 50

HOURS

EVERY

100

HOURS

EVERY 200

HOURS

Engine oil

check the level ●

change ● ●

Air filter

check ●

replace ٭

Spark plug

check/adjust ●

replace ●

Gearbox oil

Check the level ●

replace ●

Check that the engine intake grid is

clean

●

Check that tines are well-sharpened

and well-fixed

● ٭

● recommended procedure

٭ procedure to be carried out if necessary

TRANSPORTING THE MACHINE

Rotavators cannot be used on plublic roads, If the machine is to be transported on a lorry or a trailer,

lower the handlebar, engage the 1

st

gear, fasten the rotavator to the lorry/trailer using ropes or belts. If a

lifting machine is used to lift the rotavator, make sure its lifting capacity is suitable for the rotavator.

Loading...

Loading...