Translation of the Original Instructions

ROTARY TILLER – Check the oil level every 100 hours by removing the plug; the oil must almost

fill the rotary tiller box. If necessary add the same oil as for the gearbox (fig. 4, no. 3).

HELPFUL HINTS FOR PROPER USE

1) Important! Always use the clutch for forward and reverse travel.

2) Never leave the out in the rain.

3) Keep the reversing mechanism in the handlebar support clean and well oiled.

4) Never force the gearbox if the gear does not engage; give a succession of little touches on the

clutch.

5) Never strain the engine: if smoke comes out of the exhaust, the engine is toiling and must be

slowed down.

6) Even impossible ground can be tilled, but the machine must be well run-in first.

7) Check the tyre pressure often.

8) When fitting the implements (e.g. rotary tiller) take care not to damage the centring device (see

chapter on «Implements»).

END OF SEASON MAINTENANCE

Clean the machine carefully. Change the engine, gearbox and tiller gearbox oil. Clean the air filter.

Sharpen and grease the blades, replacing them if worn.

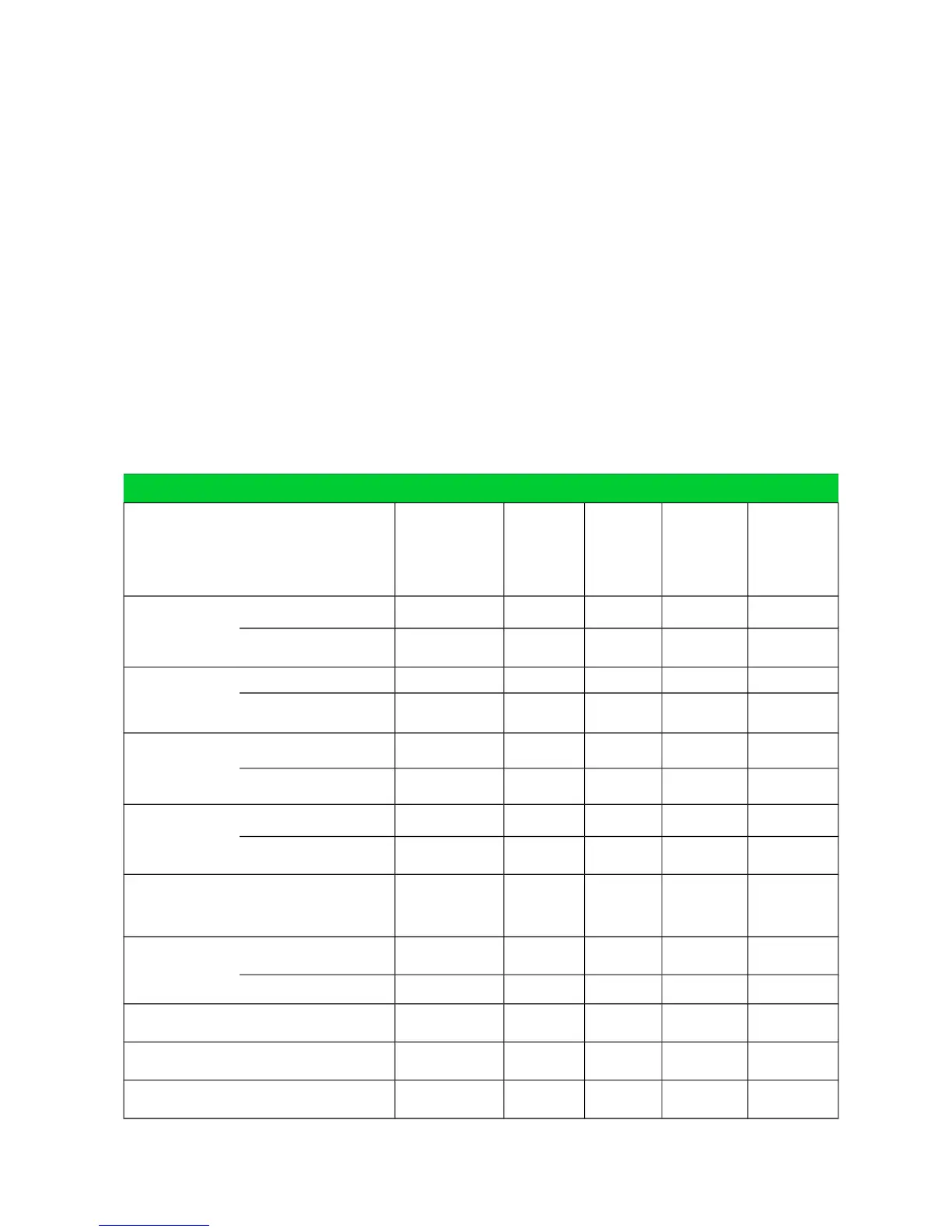

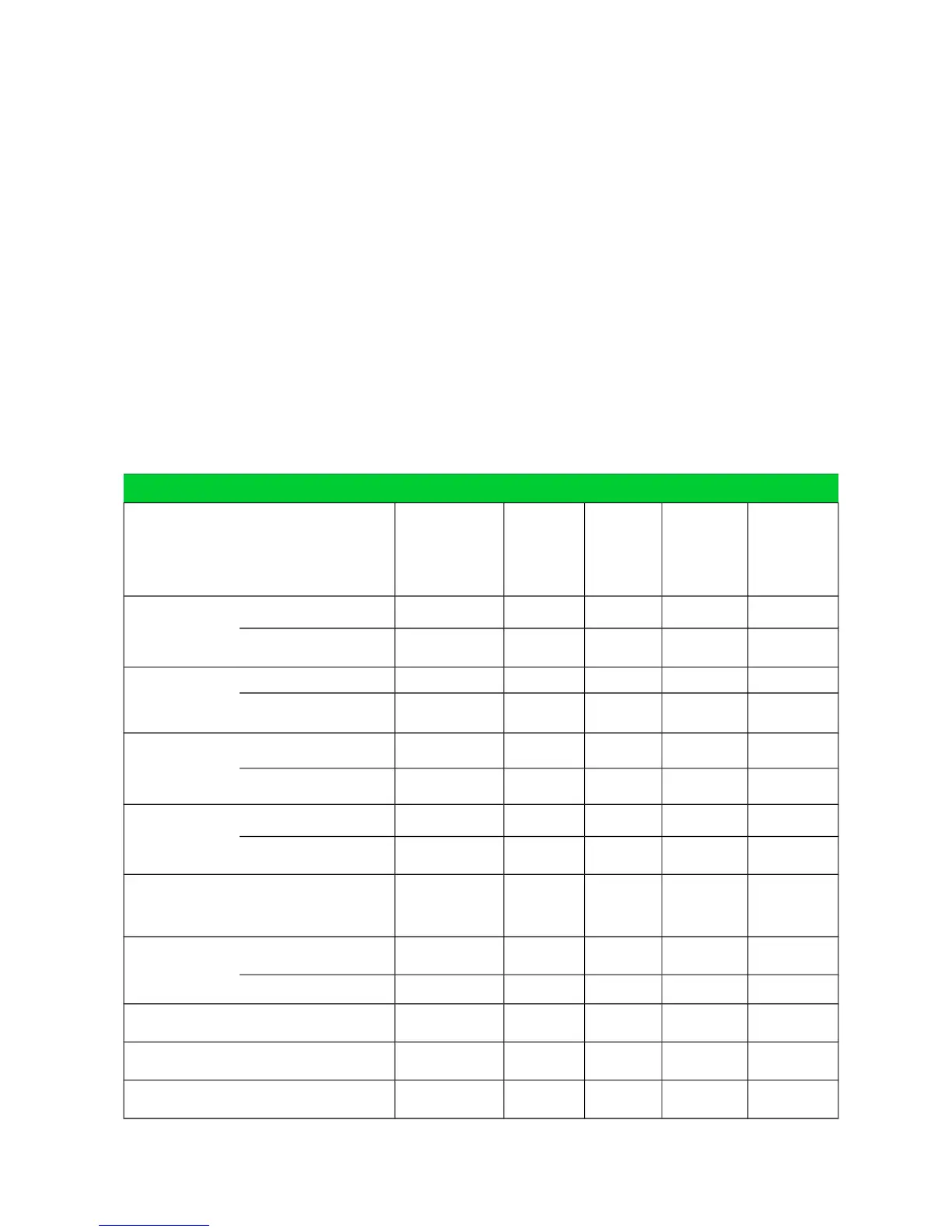

MAINTENANCE SUMMARY TABLE

PROCEDURE EVERY 8

HOURS

AFTER

20

HOURS

EVERY

50

HOURS

EVERY

100

HOURS

ONCE A

YEAR OR

EVERY

200

HOURS

Engine oil

check the level ●

change ● ●

Air filter

check ●

replace ٭

Spark plug

check/adjust ●

replace ●

Gearbox oil

Check the level ● ●

replace ●

Check that the engine intake grid is

clean

●

Cutter bar

Check blade

attachment

● ●

grease

●

Check that tines are well-sharpened

and well-fixed

● ●

Lubricate with grease

●

Check clutch clearance (free play)

● ●

● recommended procedure

٭ procedure to be carried out if necessary

12

Loading...

Loading...