16

GK2EW24120B_G Revision date: 12.06.19

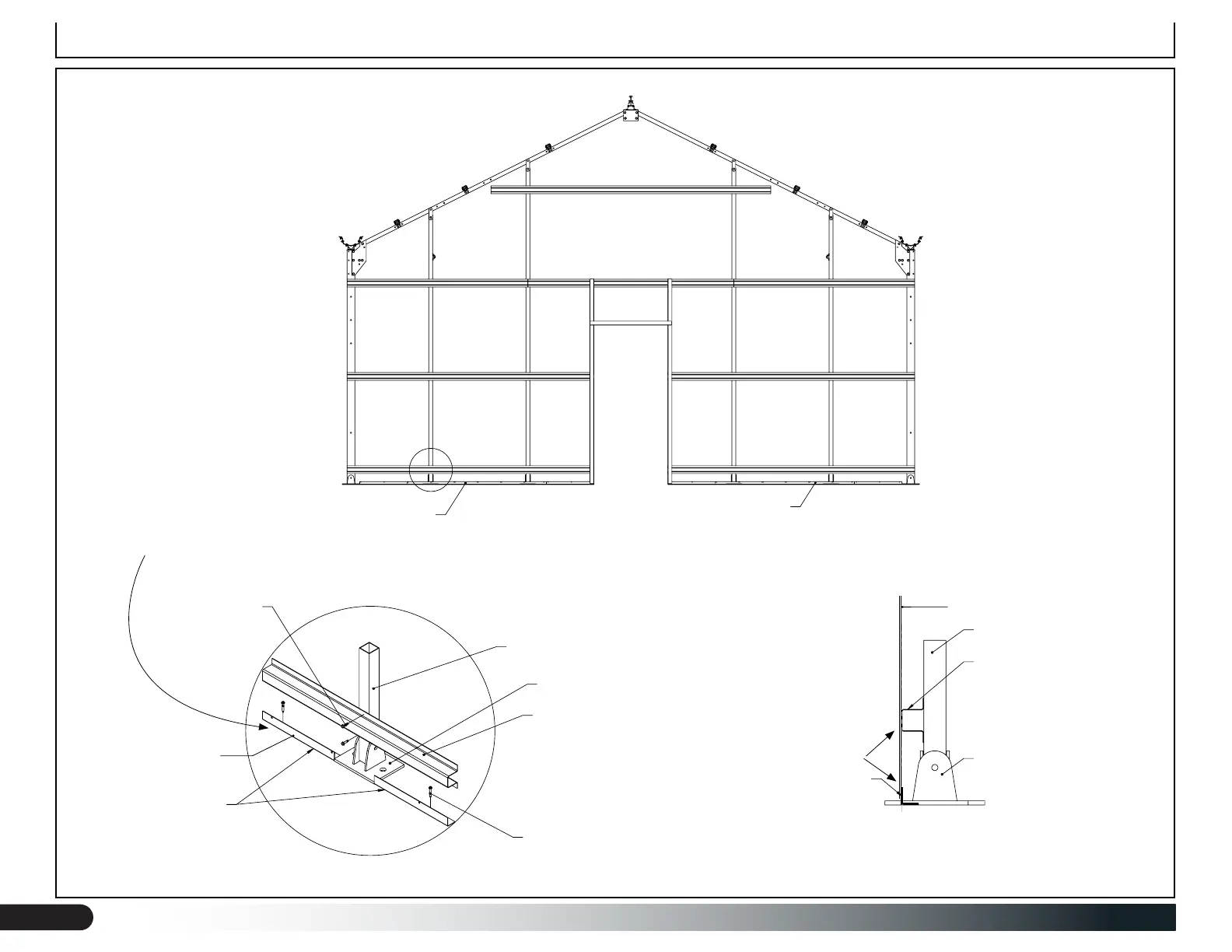

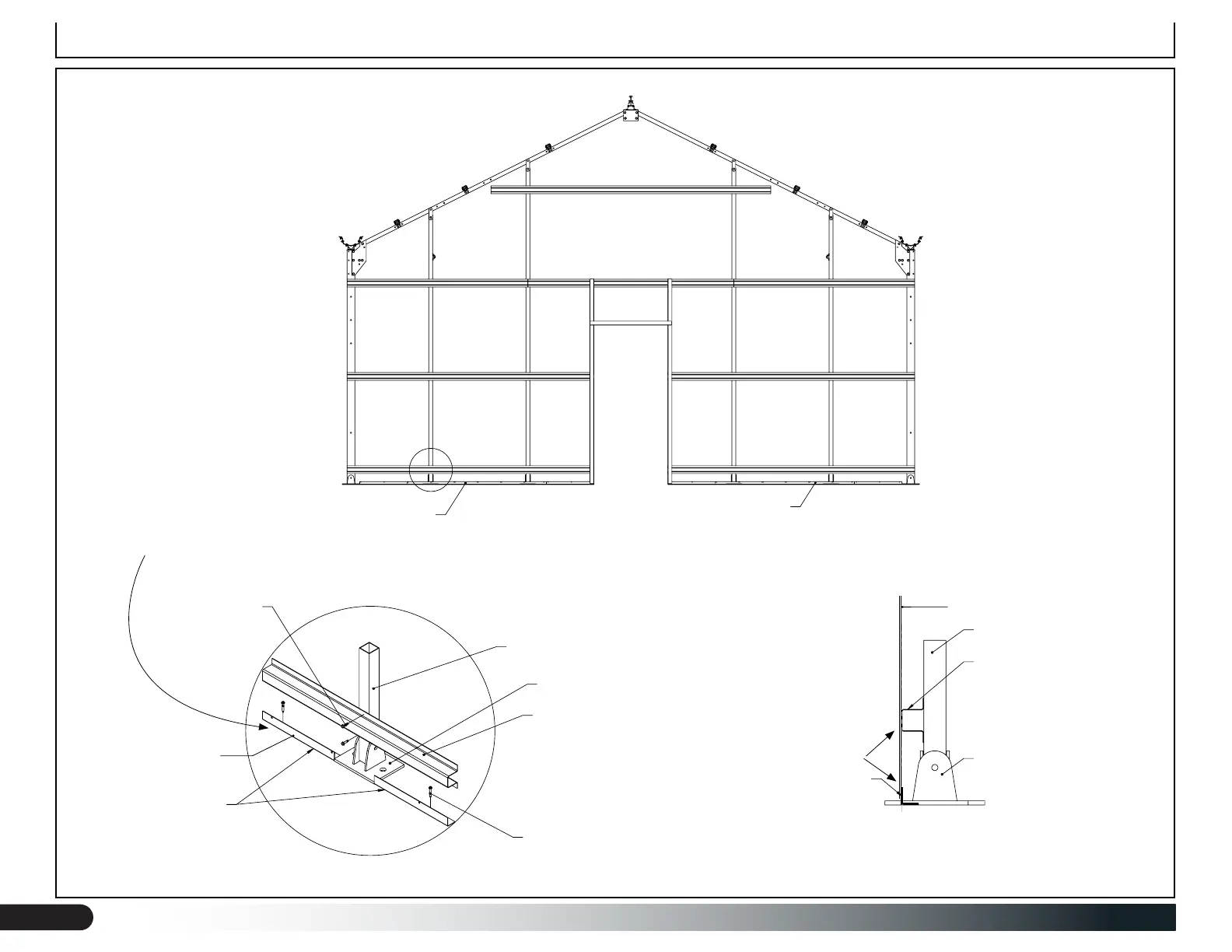

Aluminum Angle Installation Option—Base Plates Only (B)

XR2535]ALUMINUM ANGLE [

ALUMINUM ANGLE TO BE FIELD CUT TO FIT

(BASED ON ENDWALL OPTION)

ALUMINUM ANGLE DETAIL AT COLUMN BASE PLATE

ENDWALL COLUMN

OPTION ONLY

FOR USE WITH BASE PLAT

E

]

BASE PLATE (OPTION)

GIRT

FA7150- (1X) 1 3/4" TAPCON SCREW [

LUMINUM ANGLE [XR2535]

- (2X) #14 X 1" TEK SCREW

ALUMINUM ANGLE [XR2535]

ENDWALL COLUMN BASE PLAT

ENDWALL GIRT

ENDWALL COLUMN

SIDE VIEW

NOTE: ALUMINUM ANGLE SHALL

BE FLUSH TO THE GIRT FACE

AND FIELD CUT TO FIT.

NOTE: INSTALL ALUMINUM

TUBE PRIOR TO ATTACHING

BOTTOM RUN OF ENDWALL

GIRTS.

PANEL

ATTACH PANEL TO OUTSIDE

OF GIRT AND ALUMINUM.

IN SOME INSTANCES, ALUMINUM

ANGLE IS REPLACED WITH 113301

ALUMINUM TUBING. SEE NEXT

PAGE.

ATTENTION: INSTALL BOTTOM

RUN OF GIRT AFTER INSTALLING

THE ALUMINUM ANGLE.

PRE-DRILL MOUNTING HOLES IN

ALUMINUM; SPACE AT 12"-16" ON

CENTER.

APPLY SEALANT (112263) UNDER

ALUMINUM THEN SECURE TO

CONCRETE USING CONCRETE

FASTENERS INCLUDED WITH KIT.

TO PREVENT LEAKS AT THIS

CONNECTION, INSTALL PC PANEL

OVER GIRT AND ALUMINUM.

DO NOT INSTALL BEHIND

ALUMINUM.

APPLY SEALANT UNDER AND

ALONG ALUMINUM.

Loading...

Loading...