MACHINE SET-UP

CONNECT AIR SUPPLY

GraverSmith recommends 1.4 CFM (40 liters/min.) at a

minimum 45 psi (3.1 bar). Maximum input is 125 psi (8.6 bar). We

encourage reducing the air pressure from the compressor with

a regulator to 45~60psi (3.1~4.1 bar) as this ensures a stable

air pressure supply. The compressed air must be clean, dry, and

oil-free. The lter supplied with each unit is a nal lter and is not

capable of removing large amounts of water, oil, or contaminants.

If the air supply has excessive water, oil, or contaminants, an

additional lter/water trap/coalescing lter should be installed

ahead of the unit. Be sure to clean/purge all lters and water

traps regularly. IMPORTANT: Never add oil to the compressed

air for the GraverSmith. Oil can foul internal parts and cause

erratic handpiece operation. If your compressor requires oil,

YOU MUST use Coalescing Filter (#004-579) to ensure this oil

does not contaminate your compressed air.

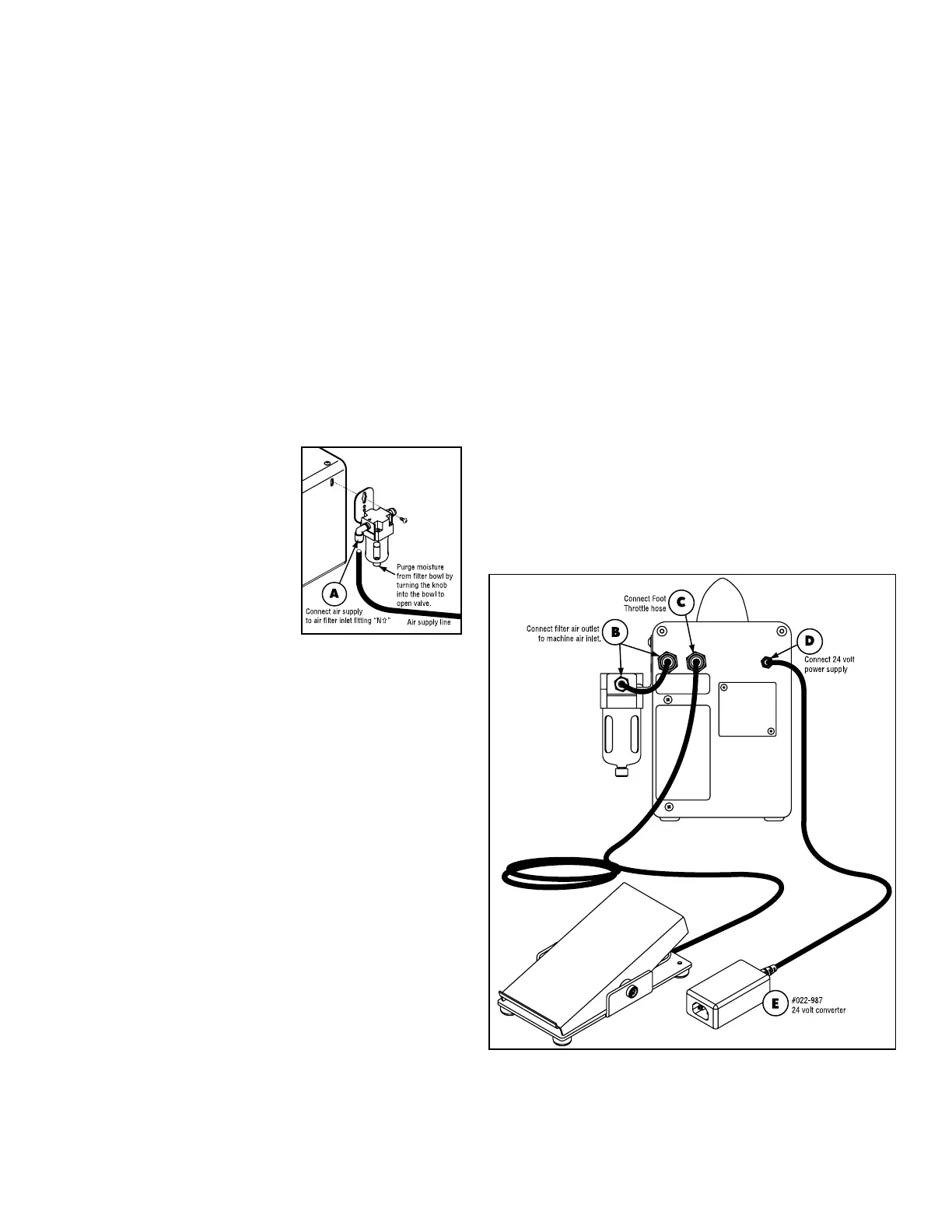

Decide where you want to locate

the machine on your bench. NOTE:

The machine must be in vertical

position - DO NOT lay on its side.

Next, decide where you would like

the air lter located. Make its location

readily accessible so it is easy to purge

moisture from the bowl. You may attach

the air lter to your machine, bench, or

wherever you desire. Keep the location

of the lter where you can see it and

easily maintain it. Here we show it

attached to the back right side of the machine (FIG. 2).

CONNECTING THE HOSES

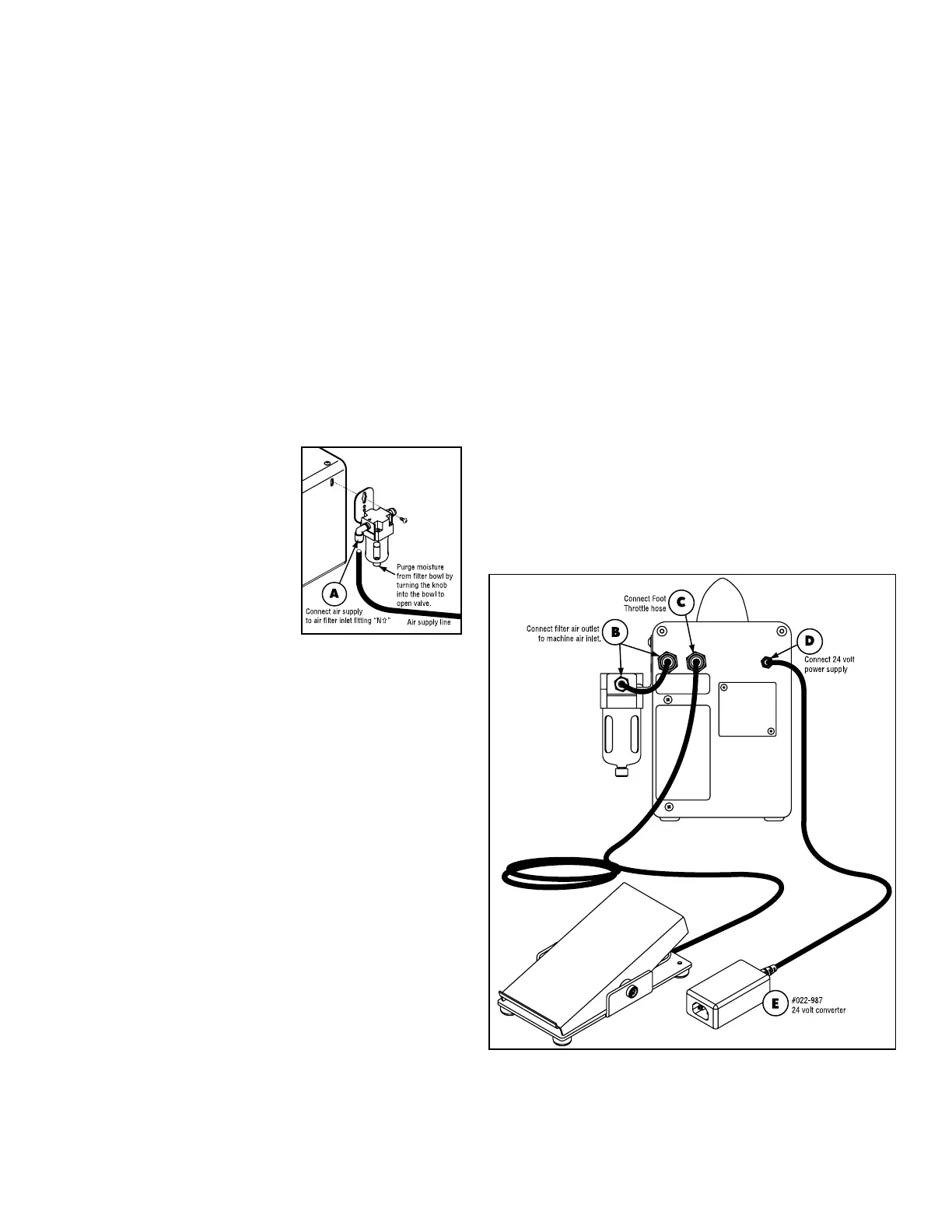

If “push-to-connect” ttings are new to you, they are amazing. With

the AIR PRESSURE SHUT OFF, simply insert the hose all the way

into the tting opening –– it stays attached. To disconnect, press in

on the orange ring while gently pulling the hose out.

Locate the air input tting on the air lter. It is identied on the

air lter with the marking “N

”. Connect your 1/4" OD (6,35mm)

air supply hose directly to the “push-to-connect” tting simply by

pushing the hose end inside the orange ring receiver (A). If your

air supply hose is larger than 1/4" OD you have two options. Use

a reducer, not supplied, and step the air hose size down to a 1/4"

OD (6,35mm), or replace the “push-to-connect” tting with the

included barbed tting and attach air supply hose.

Locate the 6' (1.82m) air hose (#044-069) and cut a 5 1/2"

(139mm) piece from it. NOTE: This is if you are going to locate the

Air Filter as described above. Connect this 5 1/2" hose to the air

outlet (FIG. 3-B) on the air lter, opposite the air input. Connect

the other end of that hose into the tting on the back of the

machine (FIG. 3-B) marked AIR INPUT on the label below it. Use

these same connections no matter where you locate the lter.

CONNECT FOOT THROTTLE

Place the foot throttle on the oor in a convenient position. Run

the hose to the back of the machine. If you need to “snake” the

hose through an opening on your bench, make sure the hose is

not pinched or kinked. Connect the hose from the foot throttle to

the “push-to-connect” tting above the label marked THROTTLE

CONNECTION (FIG. 3-C).

CONNECT ELECTRICAL POWER

IMPORTANT: The ROTARY VALVE is lubricated by air

passing through it. DO NOT RUN THE MACHINE UNLESS

AIR SYSTEM IS ON.

Connect the electrical power cord into the 24 Volt Converter Box

(FIG. 3-E). Plug the converter cord into the jack on the back of

the machine (FIG. 3-D). IMPORTANT NOTE: DO NOT USE

OTHER BRANDS OF 24 Volt Converters - DAMAGE WILL

OCCUR to the machine.

The power converter supplied with your machine will accept 120

Volt or 230 Volt. All that is necessary to convert power supply is

to use the 230 Volt adapter supplied in the accessory box. You

are ready to tune the handpiece.

FIG. 3

FIG. 2

Loading...

Loading...