OPERATION

STROKES PER MINUTE (SPM)

Stroke speed setting is a matter of personal preference and

experience. Generally speaking, lower speed settings are

preferred for some stippling, matting or staking functions. Try mid-

range settings for tasks requiring maximum power. Higher speeds

work best for ne, delicate cuts and to obtain the best nish.

The GraverSmith shows a range of 400 to 8,000 strokes per

minute. The calibrations on the dial are only approximate. Each

model of handpiece has a normal range of strokes per minute.

Operating outside this range can produce erratic operation at times.

HOW TO TUNE THE GRAVERSMITH

By “tuning” your machine, we mean adjusting the strokes per

minute and air pressure for optimum performance. TUNING

YOUR MACHINE PROPERLY IS THE SINGLE MOST

IMPORTANT OPERATION YOU SHOULD LEARN.

1. Turn ON your air

compressor and allow

the tank to ll. Wait for

the compressor to cycle

off and stop running.

2. Turn the GraverSmith

on and set the stroke

per minute dial

at 2300 and using the

regulator knob on the

front of the machine,

back the air pressure

down to 2 to 5 PSI (0.1

to 0.4 bar).

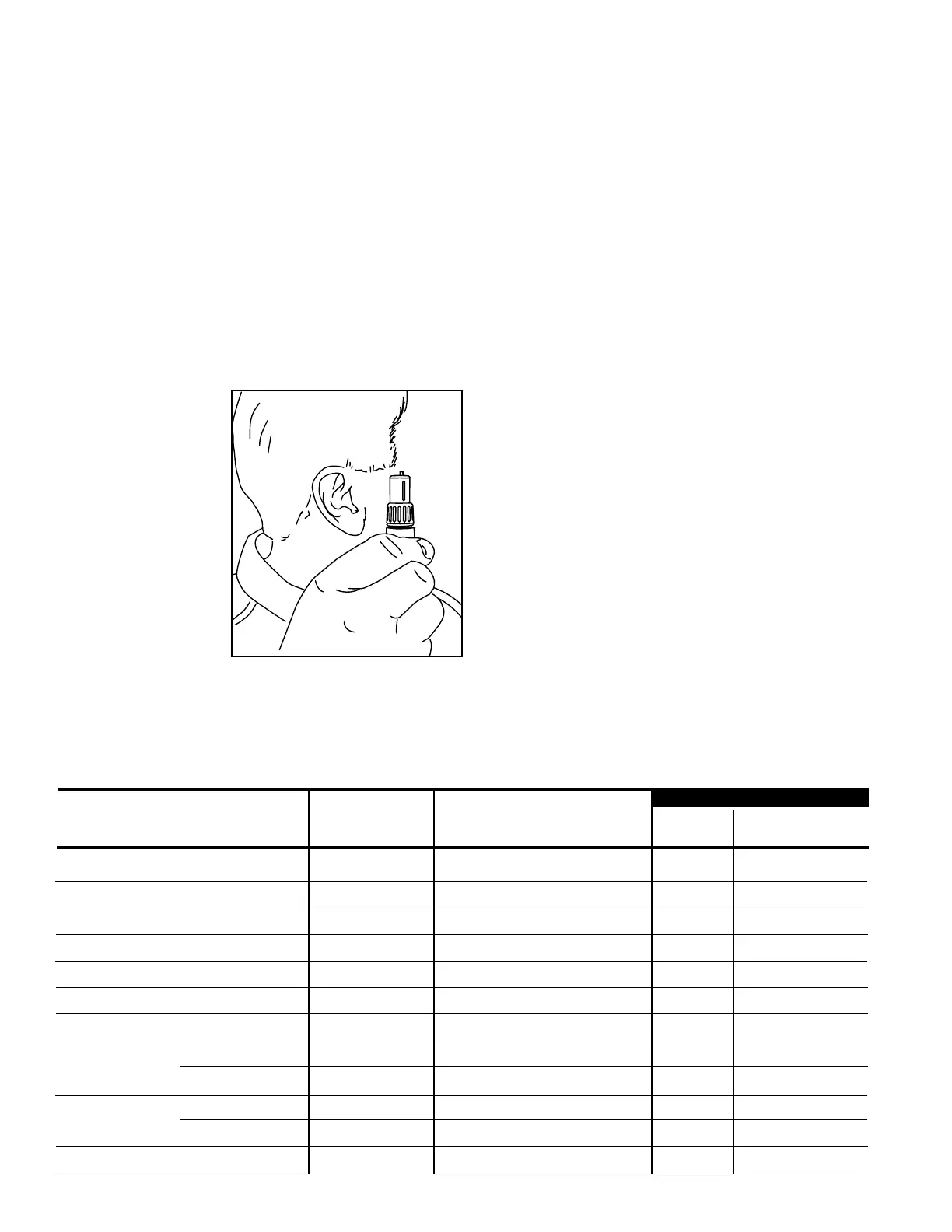

3. Hold the handpiece you

have selected to use

with the tool holder end

up (vertically) next to your ear FIG. 4).

4. WITHOUT depressing the foot control, SLOWLY increase

the air pressure until the handpiece begins to buzz. While

continuing to increase the air pressure, the handpiece will

vibrate, more air pressure will make it knock. Slowly add air

pressure and when the knocking barely stops and add 2 psi

(.13 bar), this is considered the perfect air pressure operating

range for any of the handpieces listed in the chart at the

bottom of the page.

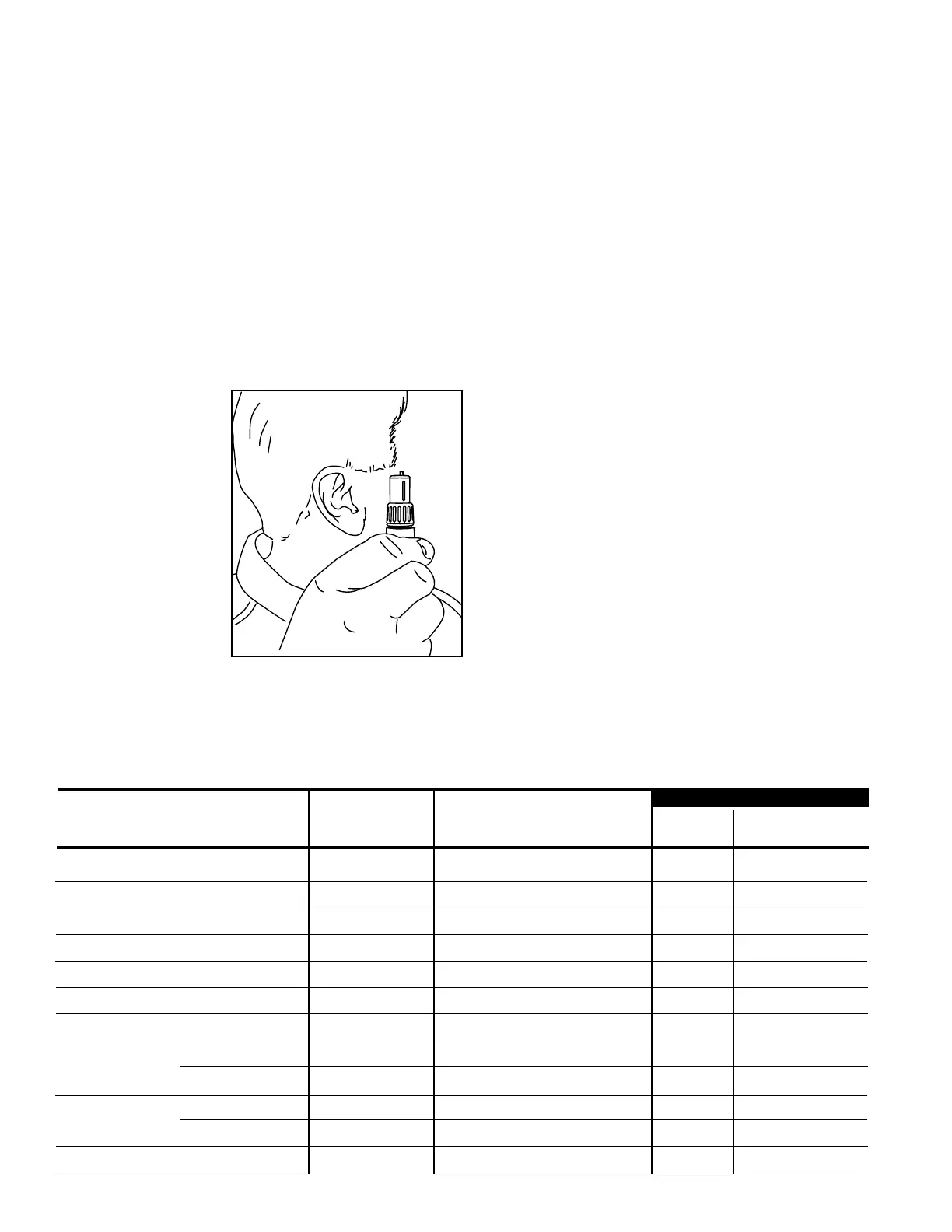

Another method of tuning (although not as precise) is to use

the initial setting shown in the chart below. Set the Strokes

Per Minute dial to the Recommended Initial Setting. Set the air

regulator knob to the middle of the Normal Air Pressure Range

for the handpiece you are using. The goal is to use the least air

pressure possible that will properly operate the handpiece.

Remember, if the handpiece vibrates without depressing the foot

control, the air pressure is probably too low. If the handpiece

fades out at full throttle, the air pressure is probably too low,

or the strokes per minute is too high for that handpiece. The

handpiece should start to operate within 3/8" (9,525mm) of

depression of the foot control, if it doesn’t the air pressure is

probably too high. Always make small adjustments in air pressure

or strokes per minute, not large ones, until you are familiar with

your machine.

If you have “tuned” your machine properly, the handpiece will

operate smoothly and predictably. New operators often use too

much air pressure or the incorrect strokes per minute range.

This can make your machine difcult to control for ne work.

The GraverSmith has excellent control for the smallest stone

setting and the nest engraving. But, you must learn to “tune” the

machine correctly to achieve this ne control! After a while, you

can experiment with variations in air pressure and stroke speed

to suit your work preference.

HANDPIECE Tuning Chart

004-506 Large 800 - 2400 20 - 30 psi (1.4 - 2.1 bar) 1400 24 psi (1.6 bar)

004-508 Standard 1000 - 2800 18 - 23 psi (1.2 - 1.6 bar) 2000 20 psi (1.4 bar)

004-563 Bulino 1600 - 4000 19 - 23 psi (1.3 - 1.6 bar) 3000 20 psi (1.4 bar)

004-610 / 609 Hammer 1000 - 2700 20 - 25 psi (1.4 - 1.7 bar) 1800 22 psi (1.5 bar)

004-710 Hammer 1000 - 2700 20 - 25 psi (1.4 - 1.7 bar) 1800 22 psi (1.5 bar)

004-801 / 810 1800 - 4000 21 - 25 psi (1.5 - 1.7 bar) 3000 22 psi (1.5 bar)

004-720 Heavy-Duty 800 - 2400 20 - 30 psi (1.4 - 2.1 bar) 1400 24 psi (1.6 bar)

Standard Spring 1400 - 3400 18 - 22 psi (1.2 - 1.5 bar) 2700 19 psi (1.3 bar)

004-901/9 10 - Fine Spring 1600 - 3600 12 - 15 psi (0.8 - 1.0 bar) 3000 13 psi (0.9 bar)

Standard Spring 2300 - 4000 11 - 14 psi (0.7 - 0.9 bar) 3600 12 psi (0.8 bar)

Fine Spring 2300 - 4000 5 - 9 psi (.34 - .62 bar) 3600 7 psi (0.4 bar)

004-940 Magnum 800 - 3400 20 - 23 psi (1.3 - 1.5 bar) 2400 21 psi (1.4 bar)

Normal Air

Pressure Range

psi (bar)

Normal

Operating Range

Strokes Per Minute

Recommended Initial Setting

Air Pressure

psi (bar)

Handpiece Type

Strokes

Per Minute

004-921

Monarch

004-901 / 910

FIG. 4

Loading...

Loading...