English (US)

8

7.5 EMC-correct installation

This section gives guidelines for good practice when installing the

CU331SP. Follow these guidelines to meet EN 61800-3, first

environment.

• Use only motor and signal cables with a braided metal screen

in applications without output filter.

• There are no special requirements to supply cables, apart

from local requirements.

• Leave the screen as close to the connecting terminals as

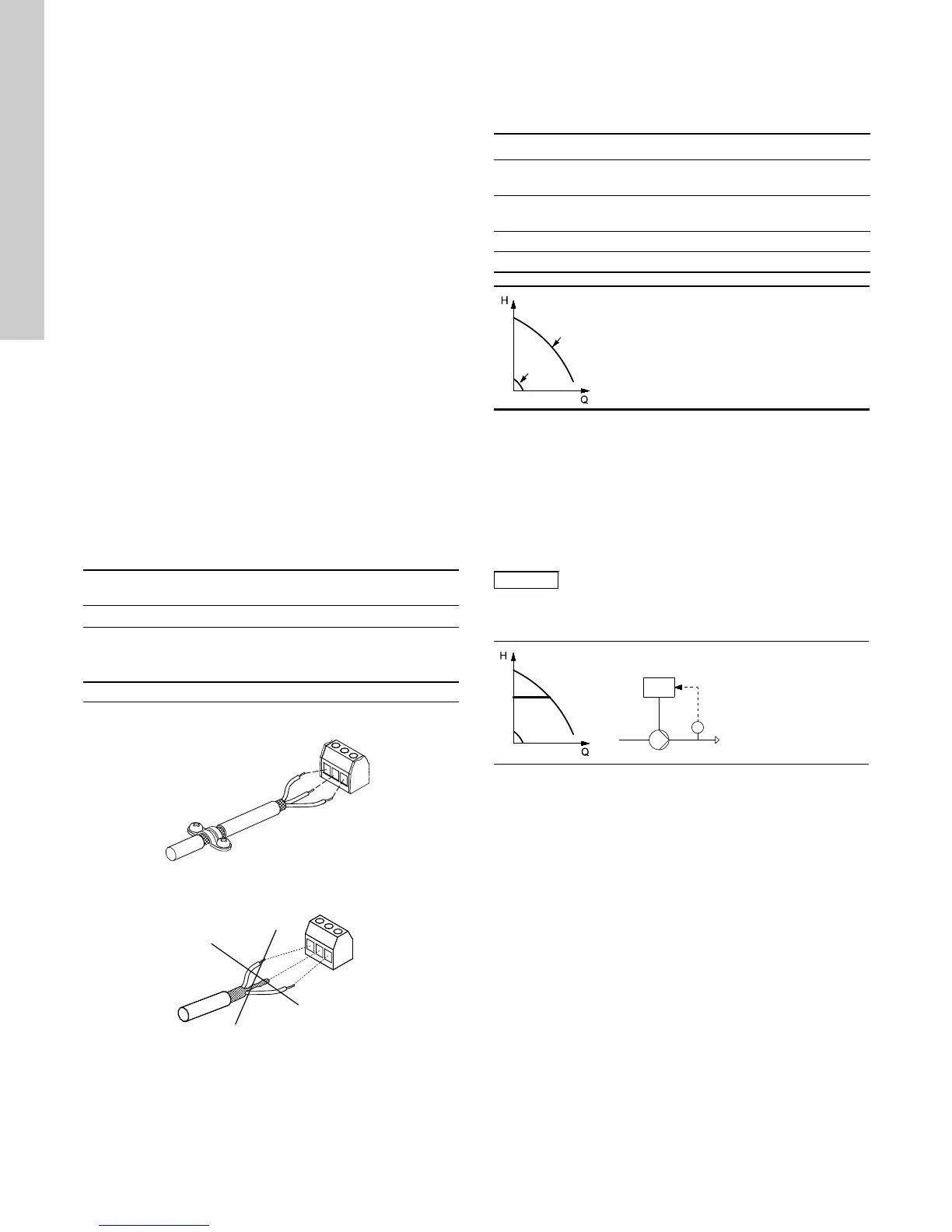

possible. See fig. 17.

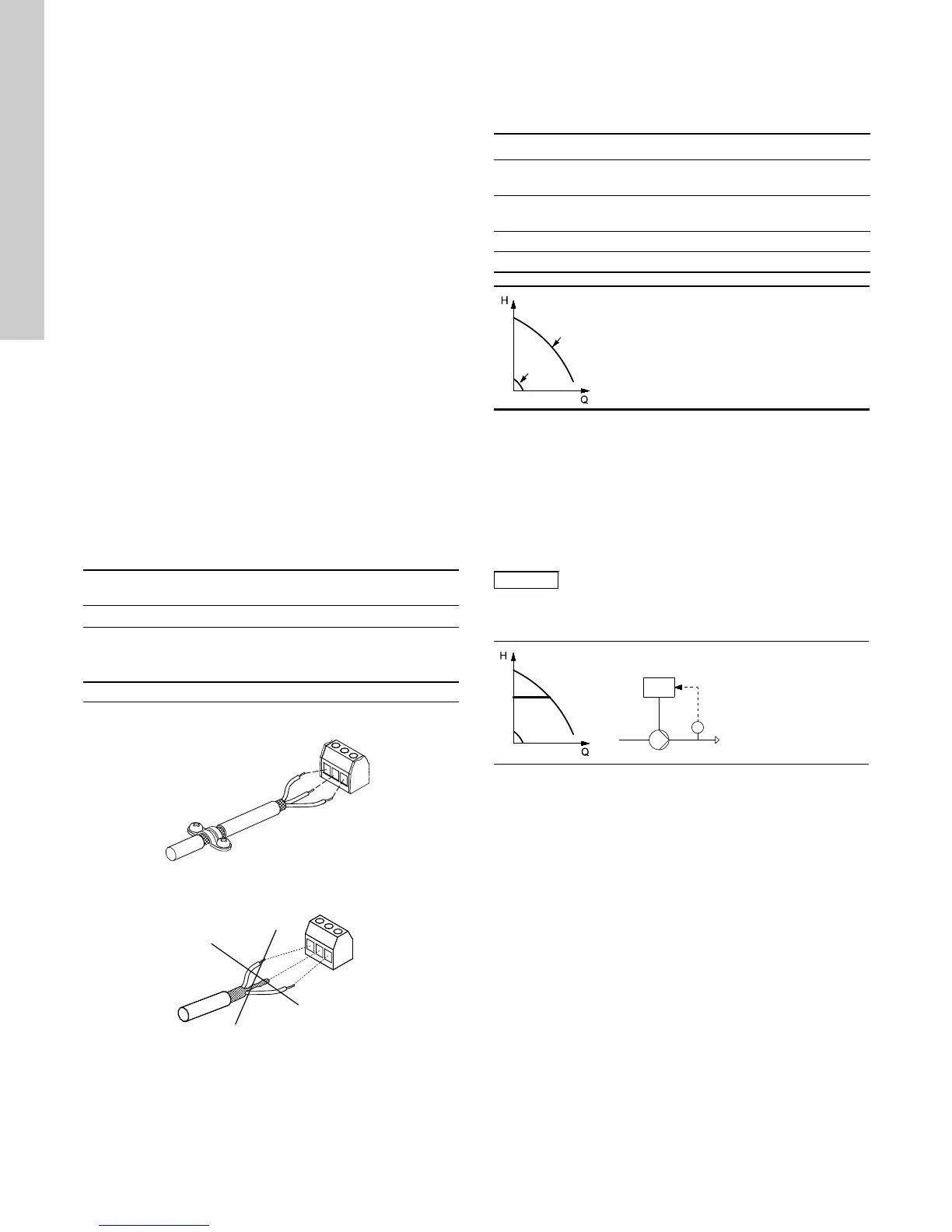

• Avoid terminating the screen by twisting the ends. See fig.18

18. Use cable clamps or EMC screwed cable entries instead.

• Connect the screen to frame at both ends for both motor and

signal cables. If the controller has no cable clamps, connect

only the screen to the CU331SP.

• Avoid unscreened motor and signal cables in electrical

cabinets with variable frequency drives.

• Make the motor cable as short as possible in applications

without output filter to limit the noise level and minimise

leakage currents.

• Screws for frame connections must always be tightened

whether a cable is connected or not.

• Keep main cables, motor cables and signal cables separated

in the installation, if possible.

Other installation methods may give similar EMC results if the

above guidelines for good practice are followed.

7.6 RFI filters

To meet the EMC requirements, the CU331SP comes with the

following types of built-in radio frequency interference filter (RFI).

*Single-phase input - three-phase output.

Description of RFI filter types

RFI filter types are according to EN61800-3

Fig. 17 Example of stripped cable with screen

Fig. 18 Do not twist the screen ends

8. Operating modes

The following operating modes are set on the control panel in

menu OPERATION, display 1.2. See 11.5.2 Operating mode

(1.2).

Example: Max. curve operation can for instance be used in

connection with venting the pump during installation.

Example: Min. curve operation can for instance be used in

periods with a very small flow requirement.

9. Control mode

The control mode of the CU331SP is:

• Controlled operation (closed loop) with a sensor connected.

9.1 Controlled operation (closed loop)

Voltage Typical shaft power P2 RFI filter type

1 x 200-240 V * 1.5 - 10 hp C1

C1: For use in domestic areas.

TM02 1325 0901TM03 8812 2507

Operating mode Description

Normal

The pump is running in the control mode

selected

Stop

The pump has been stopped (green indicator

light is flashing)

Min. The pump is running at minimum speed

Max. The pump is running at maximum speed

TM03 8813 2507

Min. and max. curves.

The pump speed is kept at a given

set value for minimum and maximum

speed, respectively.

This cannot be changed

TM03 8476 1607

TM03 8805 2507

Constant pressure.

The pressure is

kept constant,

independently of

the flow rate.

Loading...

Loading...