English (GB)

5

4.1.3 Grundfos MMS6, MMS 8000, MMS 10000 and

MMS 12000 submersible motors

Filling procedure:

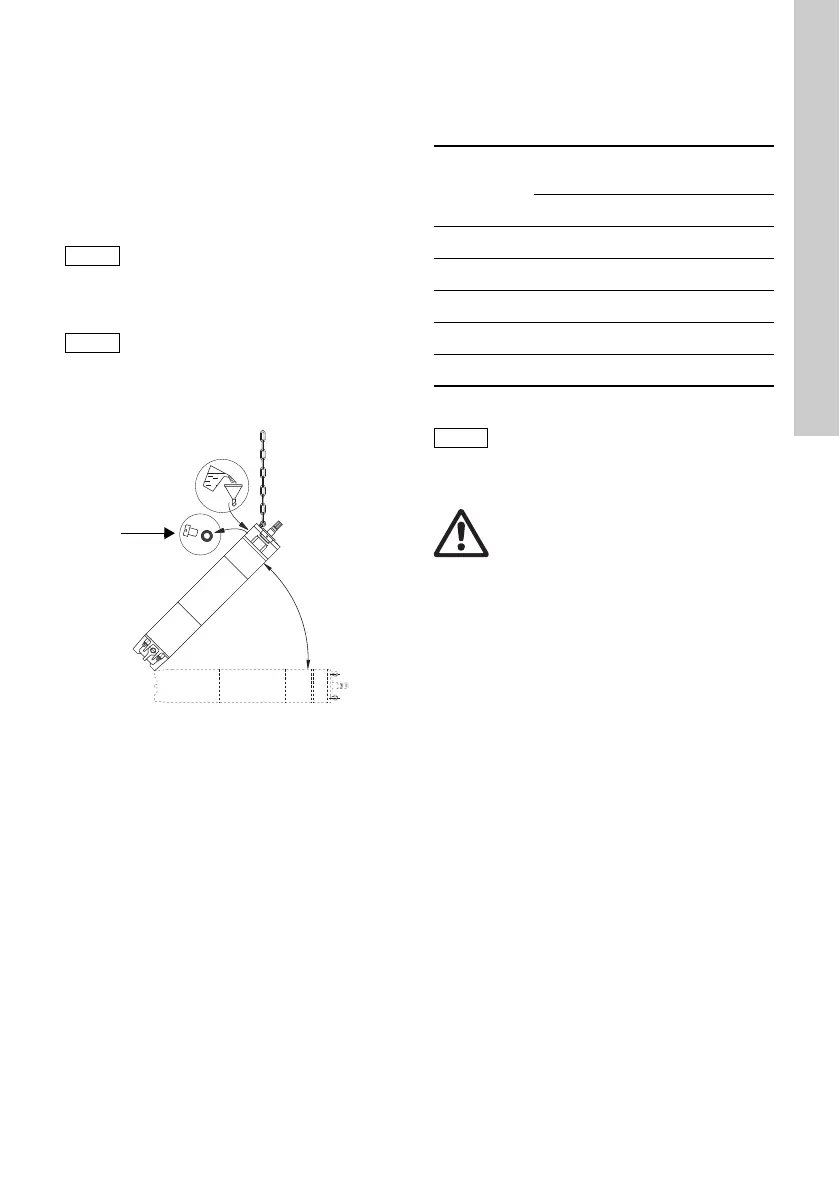

Place the motor at a 45 ° angle with the top of the

motor upwards. See fig. 5.

1. Unscrew the plug (A) and place a funnel in the

hole.

2. Pour tap water into the motor until the motor

liquid inside the motor starts running out at the

plug (A).

3. Remove the funnel and refit the plug (A).

The submersible motor is now ready for assembly

with the pump and ready for installation.

Fig. 5 Motor position during filling - MMS

4.2 Positional requirements

The motor can be installed either vertically or

horizontally.

4.2.1 Motors suitable for horizontal installation

Do not use motor liquid that contains oil.

Before fitting the motor to a pump after a

long period of storage, lubricate the shaft

seal by adding a few drops of water and

turning the shaft.

TM03 2065 3605

Motor type

Output power

50 Hz

Output power

60 Hz

[kW] [kW]

MS All sizes All sizes

MMS6 5.5 - 37 5.5 - 37

MMS 8000 22-92 22-92

MMS 10000 75-170 75-170

MMS 12000 147-190 -

During operation, the motor must always

be completely submerged in the liquid.

Please consult the pump manufacturer's

NPSH data.

Warning

If the motor is used in hot liquids

(40-60 °C), make sure that no one can

come into contact with the motor and the

installation, e.g. by installing a guard.

www.motralec.com / service-commercial@motralec.com / 01.39.97.65.10

Loading...

Loading...