English (GB)

6

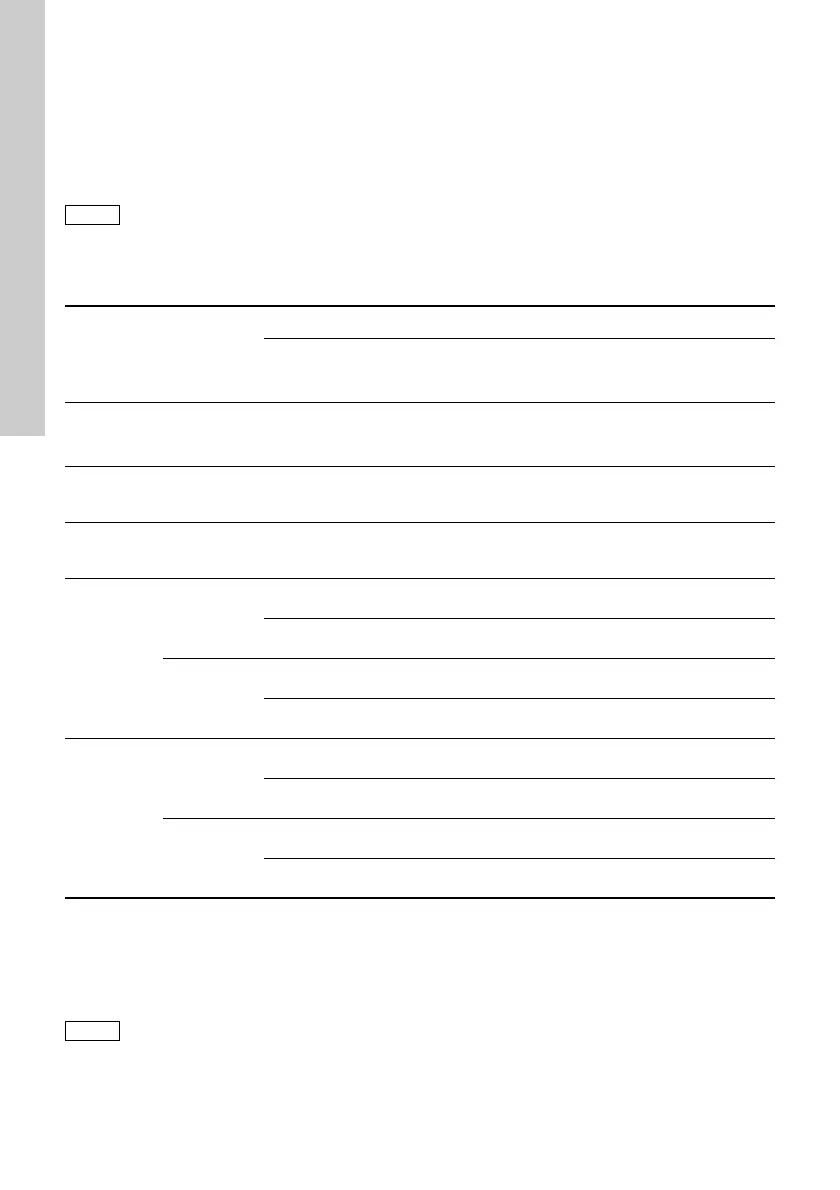

4.3 Liquid temperatures/cooling

The maximum liquid temperature and the minimum

flow velocity past the motor appear from the

following table.

Grundfos recommends installing the motor above the

well screen in order to achieve proper motor cooling

via liquid passing the motor.

If there is a risk of sediment build-up, such as sand,

around the motor, a flow sleeve should be used in

order to ensure proper cooling of the motor.

* At an ambient pressure of minimum 1 bar (0.1 MPa).

** At an ambient pressure of minimum 2 bar (0.2 MPa).

If the stated flow velocity cannot be

achieved in the borehole, a flow sleeve

must be installed.

Motor

Installation

Flow past the

motor

[m/s]

Vertical Horizontal

MS 402

MS 4000 (T40)

MS 6000 (T40)

0.15

40 °C

(~ 105 °F)

40 °C

(~ 105 °F)

MS 4000I (T60)*

MS 6000 (T60)*

1.00

60 °C

(~ 140 °F)

Flow sleeve recommended

60 °C

(~ 140 °F)

Flow sleeve recommended

MS 6000 (T60)** 0.15

60 °C

(~ 140 °F)

Flow sleeve recommended

60 °C

(~ 140 °F)

Flow sleeve recommended

MMS6

PVC

windings

0.15

25 °C

(~ 86 °F)

25 °C

(~ 86 °F)

0.50

30 °C

(~ 95 °F)

30 °C

(~ 95 °F)

PE/PA

windings

0.15

45 °C

(~ 113 °F)

45 °C

(~ 113 °F)

0.50

50 °C

(~ 122 °F)

50 °C

(~ 122 °F)

MMS 8000

to 12000

PVC

windings

0.15

25 °C

(~ 77 °F)

25 °C

(~ 77 °F)

0.50

30 °C

(~ 86 °F)

30 °C

(~ 86 °F)

PE/PA

windings

0.15

40 °C

(~ 104 °F)

40 °C

(~ 104 °F)

0.50

45 °C

(~ 113 °F)

45 °C

(~ 113 °F)

For 37 kW MMS6 (only PVC windings),

110 kW MMS 8000 and 170 kW

MMS 10000, the maximum liquid

temperature is 5 °C lower than the values

stated in the above table. For 190 kW

MMS 10000, 220-250 kW MMS 12000/50

Hz and MMS 12000/

60 Hz, the temperature is 10 °C lower.

www.motralec.com / service-commercial@motralec.com / 01.39.97.65.10

Loading...

Loading...