English (GB)

8

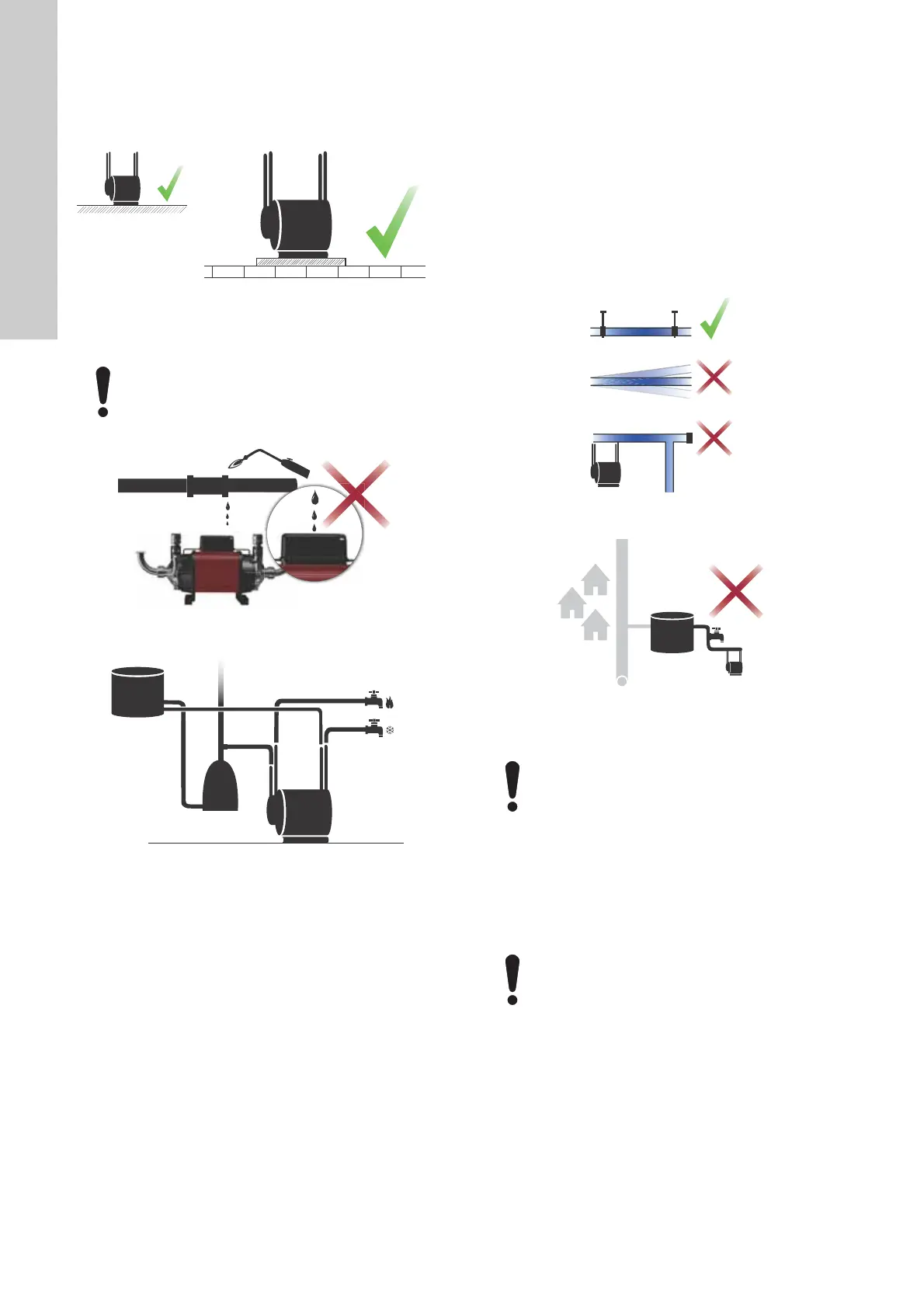

4.1.1 Foundation

Install the pump on a vibration-free foundation. In case of wooden

floors use a small concrete foundation of approx. 225 x 225 mm

and 40 to 50 mm thick.

Fig. 8 Foundation

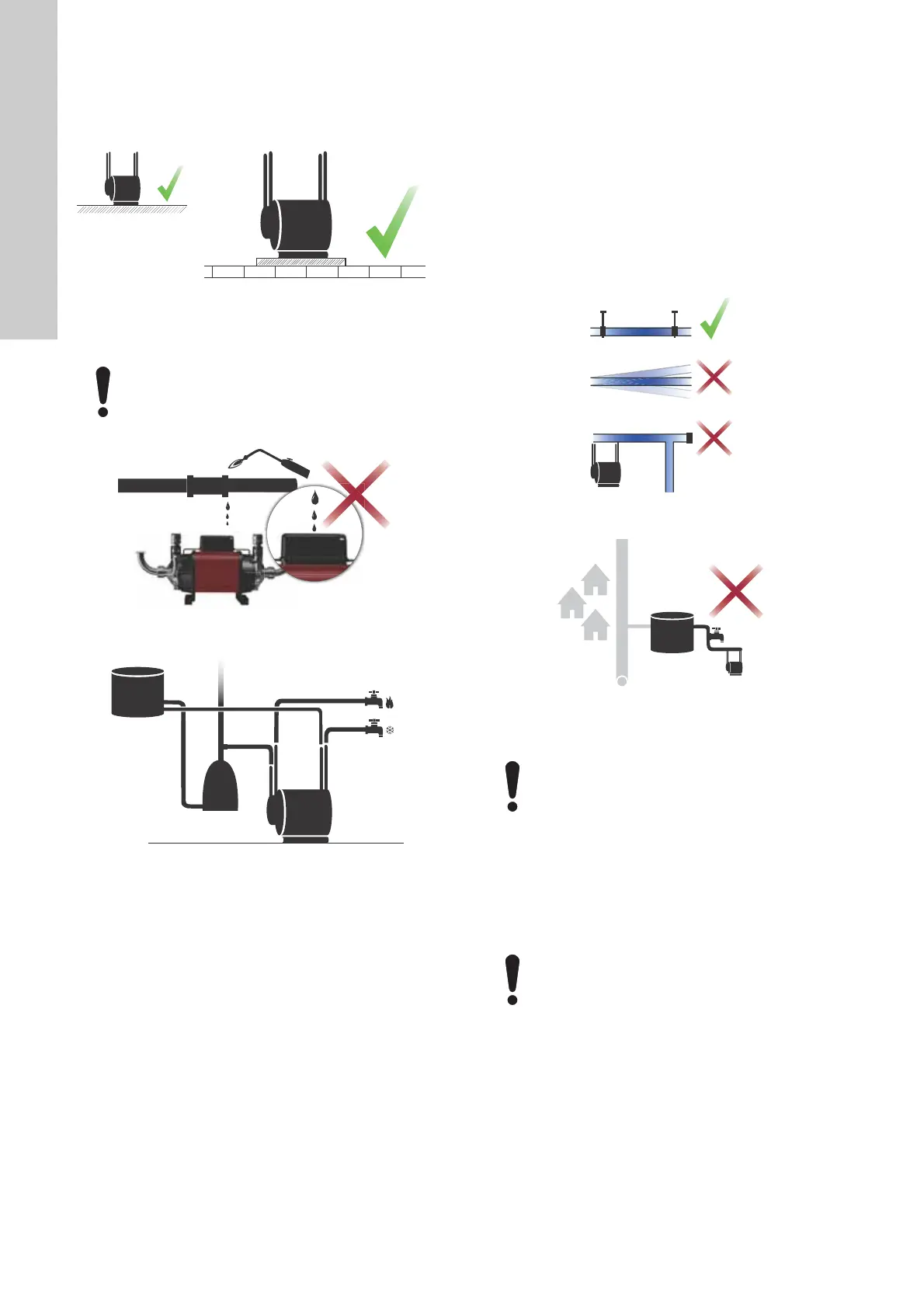

4.2 Pipes

Fig. 9 Solder flux causes damage to plastic parts

Fig. 10 Pipe connection to hot-water cylinder

Use 22 mm pipes to and from the pump.

• The expansion pipe from the hot-water cylinder should always

rise in order to prevent trapped air.

• The outlet pipe from the pump to the shower valve should rise,

where possible, to prevent trapped air.

• Pipes from the pump to the shower valve should go up and

over, rather than under floor.

• Do not fit any other outlets in the inlet pipes to the pump. See

fig. 12.

• Use dedicated supplies to hot and cold water.

• Avoid blanked-off pipes.

• Avoid restrictions in the flexible hoses.

• Secure down all pipes to minimise noise and vibration.

Fig. 11 Fixing the pipes

Fig. 12 Pipe installation examples

4.2.1 Hot-water cylinder connections

Connect the supply from the hot-water cylinder to the pump with a

dedicated supply.

Fit a surrey flange to minimise air in the hot-water supply to the

pump.

Use 22 mm pipe to ensure an adequate flow to the pump.

4.2.2 Cold-water supply

Connect the pump with a dedicated supply using 22 mm pipe

from the cold-water storage tank.

TM05 6987 0313 - TM05 6988 0313

Do not allow any solder flux to come into contact with

any of the plastic parts of the pump.

TM05 7319 1113TM05 6989 0313

> 227 litres

(50 gallons)

TM05 6974 0313TM05 6972 0313

Do not use any jointing compounds.

Do not connect the pump directly to the water mains

supply.

Do not use any jointing compounds or tape.

Loading...

Loading...